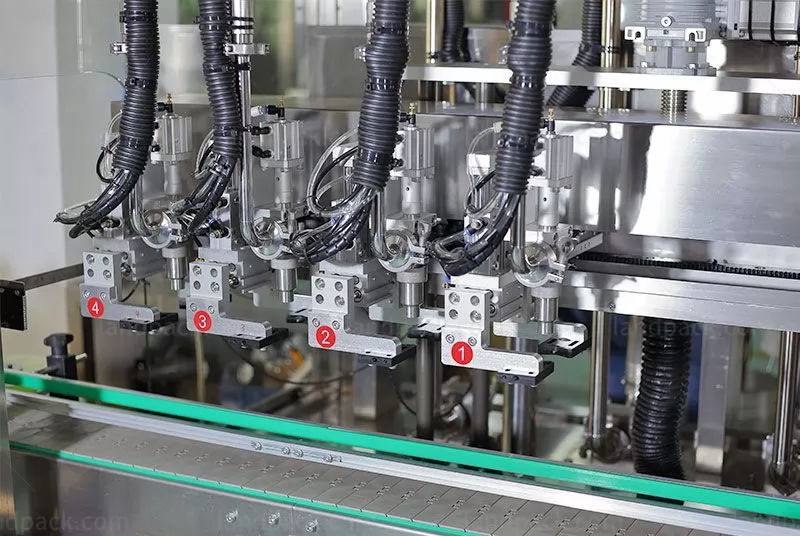

1. The filling system, lifting system and tracking system are all controlled by servo motor, with high precision; guardrail is controlled by stepper motor.

2. It is not necessary to use tools to replace products of different specifications in the whole process. The product size is controlled and debugged by the touch screen, and each product only needs to debug the formula parameters for the first time.

3. The filling head is controlled separately, and the two filling systems are separate.

4. The filling speed and filling volume can be directly input on the display screen, and the filling can be done without adjusting the mechanical parts.

5. It adopts three-speed filling or two-speed filling, and the three-stage speed and filling volume can be adjusted to prevent the liquid from splashing out after full.

6. Intelligent control, automatic photoelectric tracking, no bottle filling.

7. There is a clamping mechanism at the back end of the machine conveying; it can be connected to the back end for the transition of the back end conveying line.

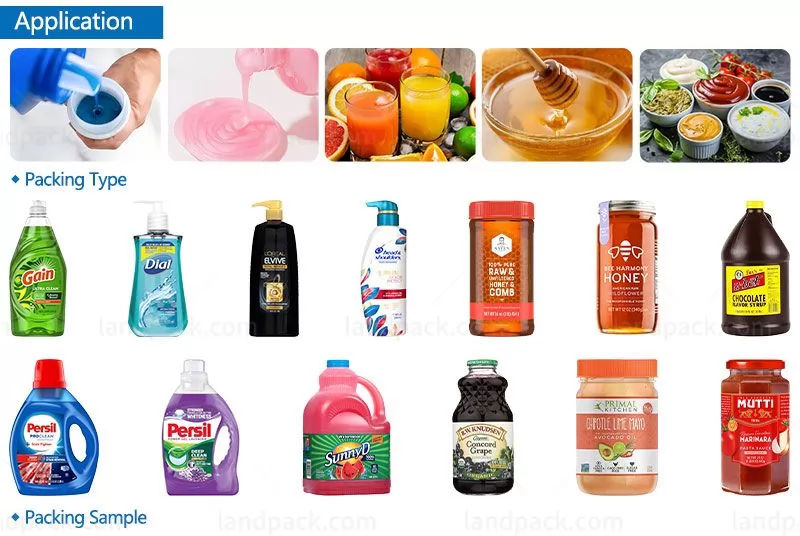

8. Fast and widely used in industries.

9. The main materials of the equipment are stainless steel and high-grade aluminum alloys, which conform to GMP production specifications. The overall structure is firm and beautiful.