Application:

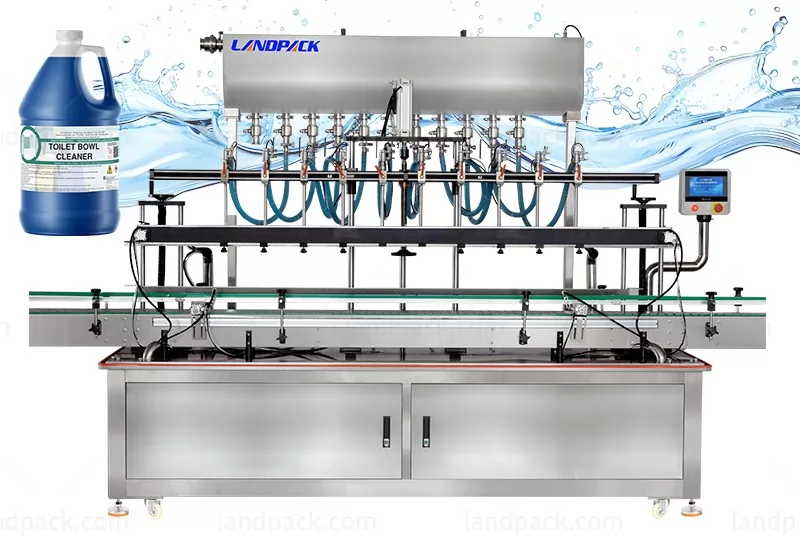

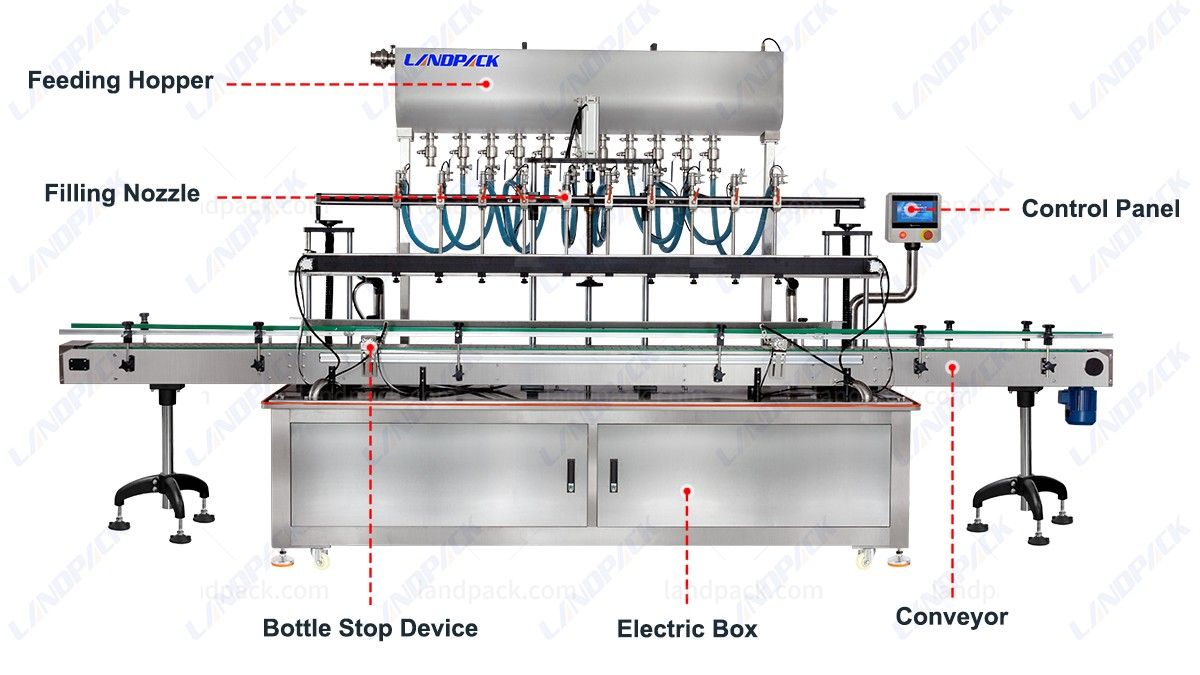

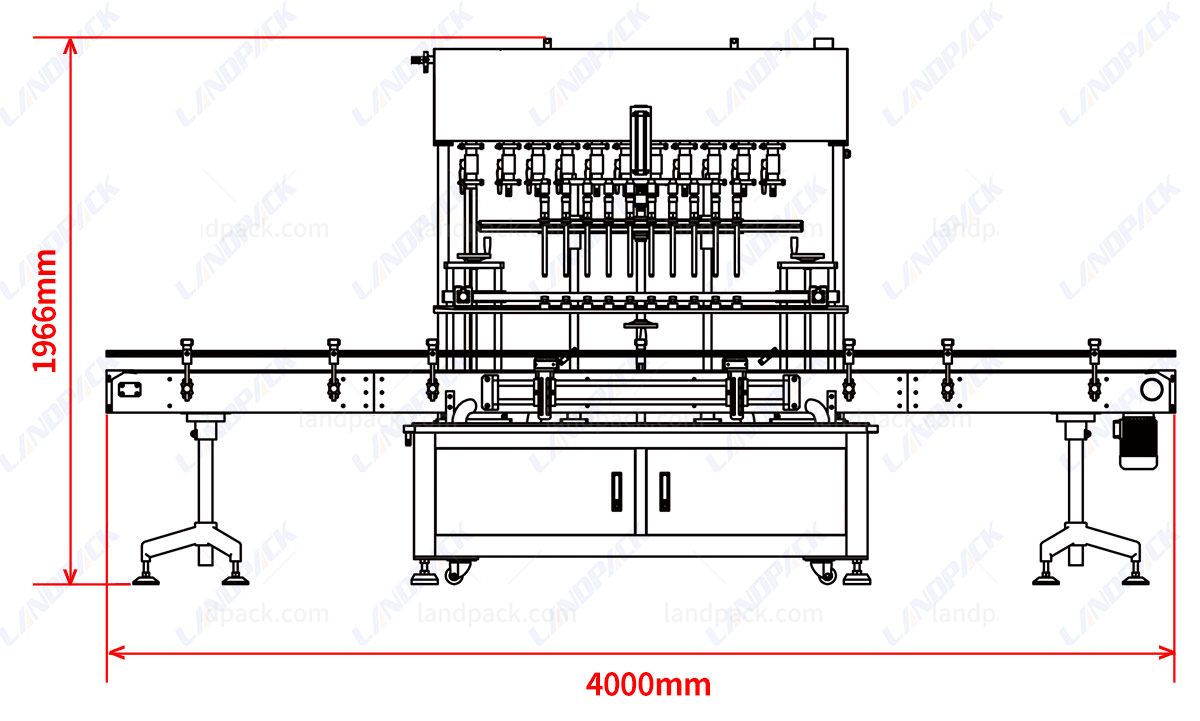

This Automatic 10 Heads Liquid Linear Bottle Filling Machine is designed to ensure accurate and efficient filling of liquids in a variety of products. It is extensively used in the production of household chemicals (detergent cleaner) as well as cosmetics (shampoo lotion, soap toner) and food and beverages (juice oil, syrup, juice) and pharmaceutical liquids. Compatible with glass bottles, plastic bottles, PET bottles and other containers that are rigid it offers reliable 60 bottles/min performance on medium-to-high production lines.

Package Type:

This machine is compatible with a wide range of liquid packaging containers, including: Plastic Bottles (HDPE / PET / PP), Glass Bottles, Round Bottles, Square Bottles, Flat & Oval Bottles, Small to Medium Volume Bottles (50ml–5L)

Suitable Products:

The liquid bottle filling machine can be used for a range of high- and low-viscosity liquids, which include:

1. Cleansing products for the home: Disinfectant, detergent, hand sanitiser, floor cleaner

2. Industrial & Chemical Liquids: Engine oil, insecticide, coolant, alcohol

3. Food & Beverage: Liquids Soy sauce, vinegar and juice concentrate, Whisky

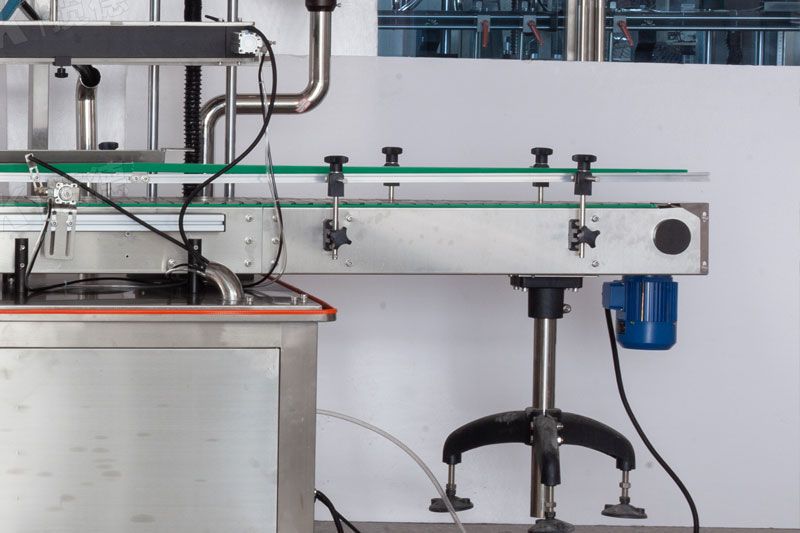

Workflow:

This is liquid filling machine for liquid products in bottles/cans. Here's how it works step-by-step:

- Bottle/Cans Feeding – Containers are automatically fed into the filling line.

- Filling – The 10-head linear system accurately fills liquid into each bottle.

- Capping/Seaming (Optional) – Automatic bottle capping or can seaming.

- Labeling (Optional) – Optional labeling for finished containers.

- Finished Product – Completed products are discharged for packing.