Application:

Ideal for filling and sealing a wide range of fluid products — from food syrups like honey and tomato sauce, to viscous condiments like mayonnaise, and personal-care or cleaning liquids such as laundry detergent, shampoo, and lotion.

Package Type:

This syrup filling line accommodates a wide variety of container formats, such as bottles, jars, jugs, and larger pails. Its flexible design supports small retail packaging, medium-sized condiment containers, and bulk containers for foodservice or industrial use.

Suitable Products:

This high-precision liquid filling line is ideal for packaging a wide variety of viscous and free-flowing liquids across food and daily-chemical industries.

- Food & Beverage Syrups and Sauces: Syrups, honey, tomato sauce, ketchup, jam, salad dressings, fruit purees.

- Condiments & Thick Pastes: Mayonnaise, chocolate spread, peanut butter, mustard, barbecue sauce, mayonnaise-style sauces.

- Daily-Chemical Liquids: Laundry detergent, hand sanitizer, shampoo, body wash, liquid soap, lotion.

Workflow:

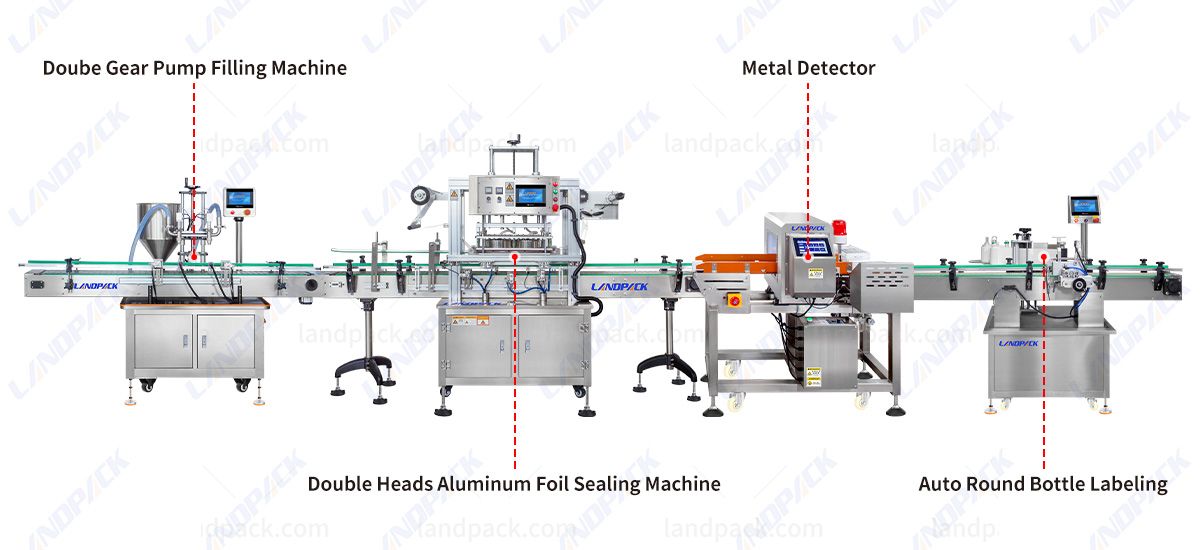

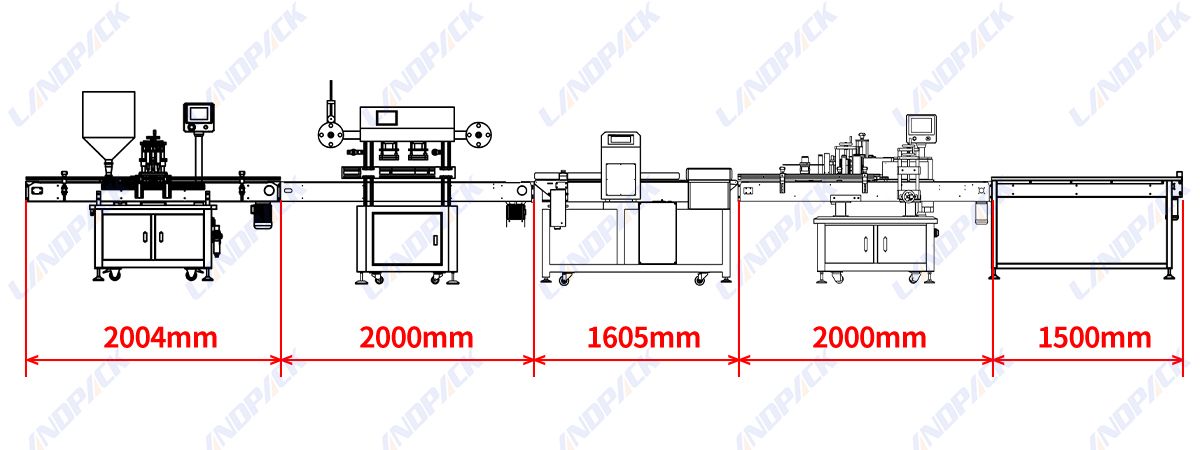

1. Container Feeding - Bottles, jars, or buckets are carried into the line through the conveyor, ensuring steady spacing for smooth downstream operations.

2. Dual-Head Gear Pump Filling - Precise gear-pump dosing fills each container with syrups, sauces, or daily-chemical liquids. The system handles different viscosities with stable, drip-free delivery.

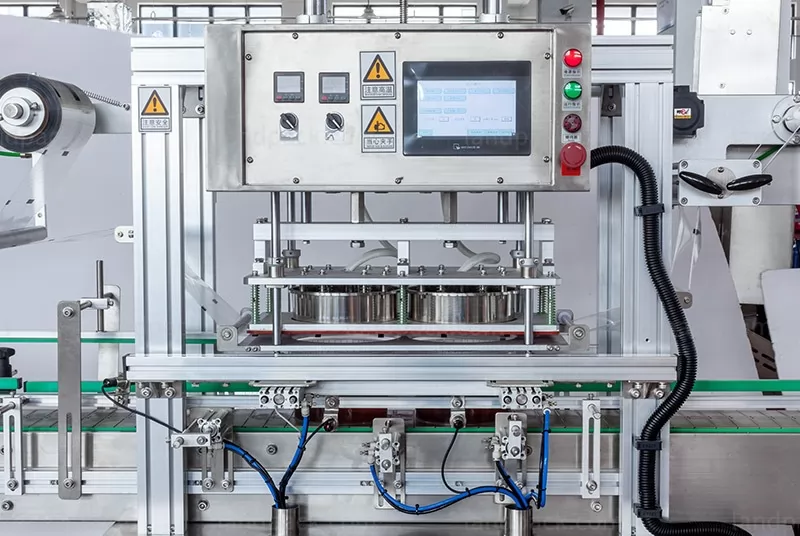

3. Aluminum Foil Sealing - The double-head foil sealer applies induction heat to bond aluminum foil securely onto the container mouth, preventing leakage and ensuring product freshness.

4. Metal Detection - Each filled container passes through a metal detector that removes any items contaminated with metal fragments, guaranteeing strict food-safety compliance.

5. Labeling - A high-accuracy round-bottle labeling system applies labels cleanly and consistently, maintaining alignment and ensuring premium product presentation.

6. Finished Product Output - Sealed and labeled containers exit onto the output conveyor, ready for final packing or carton loading, supporting efficient continuous production.