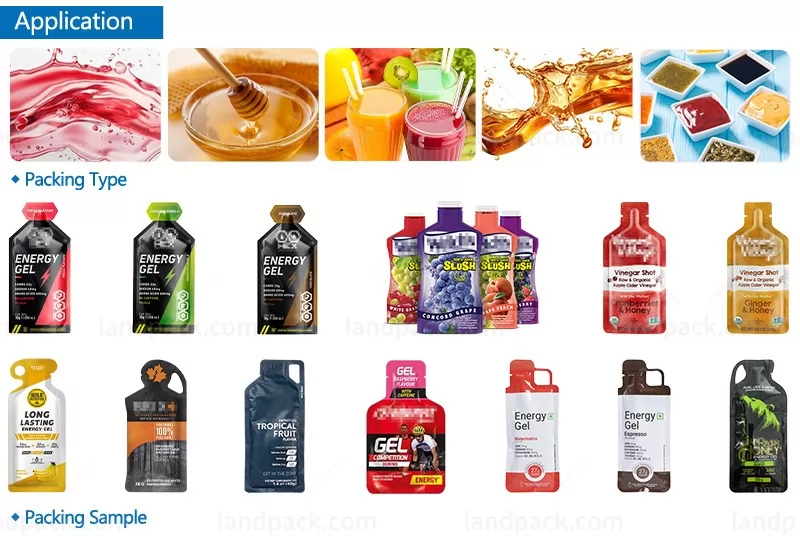

Application:

This machine can be used to fill a variety of liquids or semi-liquids including bags with custom shapes. This machine can be used to fill a variety of liquid products including cosmetics and beverages. It is also suitable for daily chemicals such as detergents, shower gels or hand washes. It is ideal for making sample bottles or sachets to use in marketing campaigns.

Package Type:

Supports numerous bag styles, offering excellent flexibility across applications.

Suitable Products:

Our bottle shaped sachet liquid packaging machine can handle a wide range of semi-liquid and liquid products. The equipment can handle a wide range of products from nutrition supplements to daily care and beverages. It is designed to ensure precise dosing and hygienic packaging.

1. Nutritional and health products: energy gels, protein drinks, Vitamins, Oral liquid medicine

2. Drinks Industry: Flavored drinks and juices, yogurt, liquid concentrates

3. Daily Care & Cosmetical Liquids: Shampoos, conditioners, lotions, liquid soap

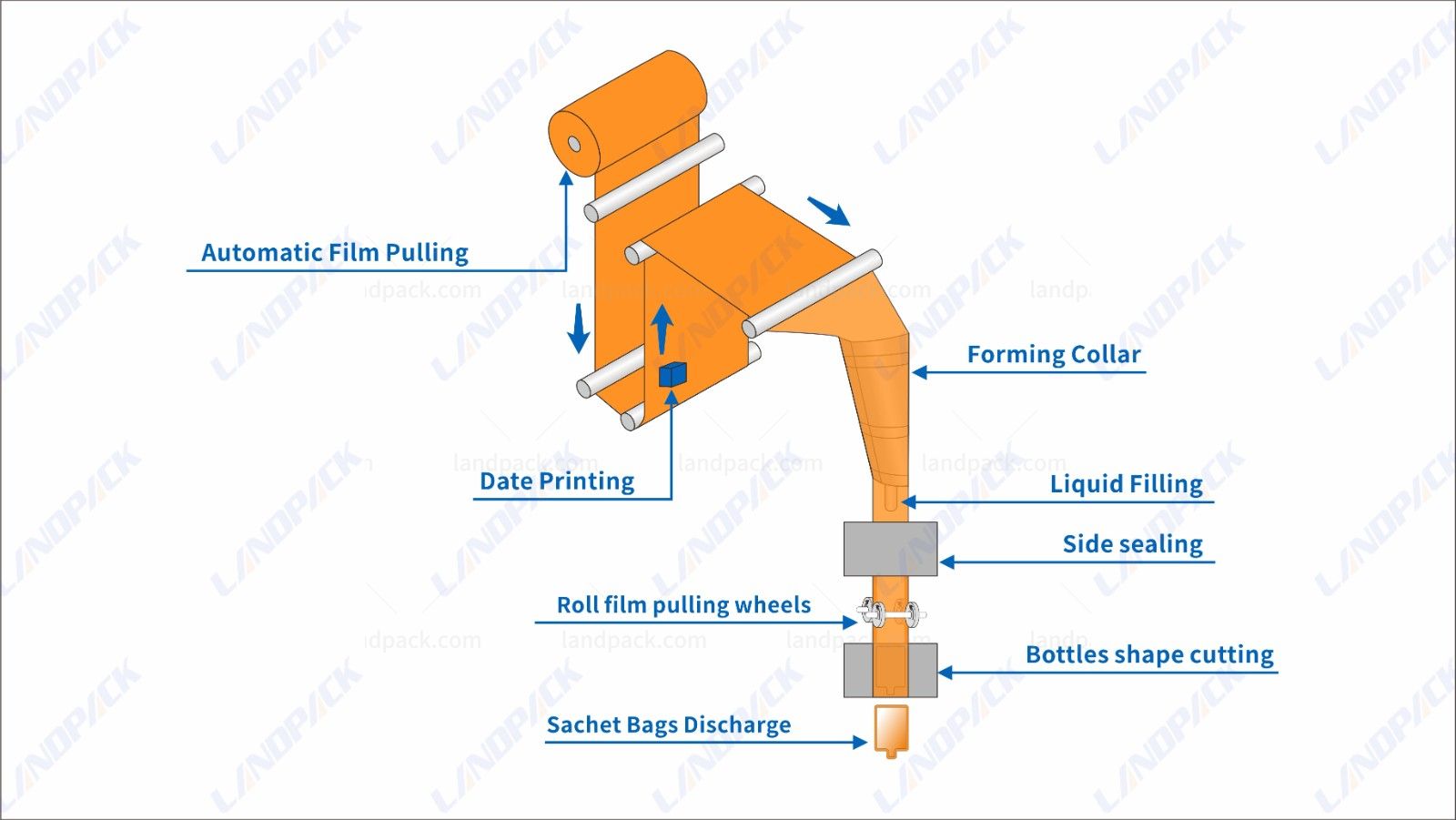

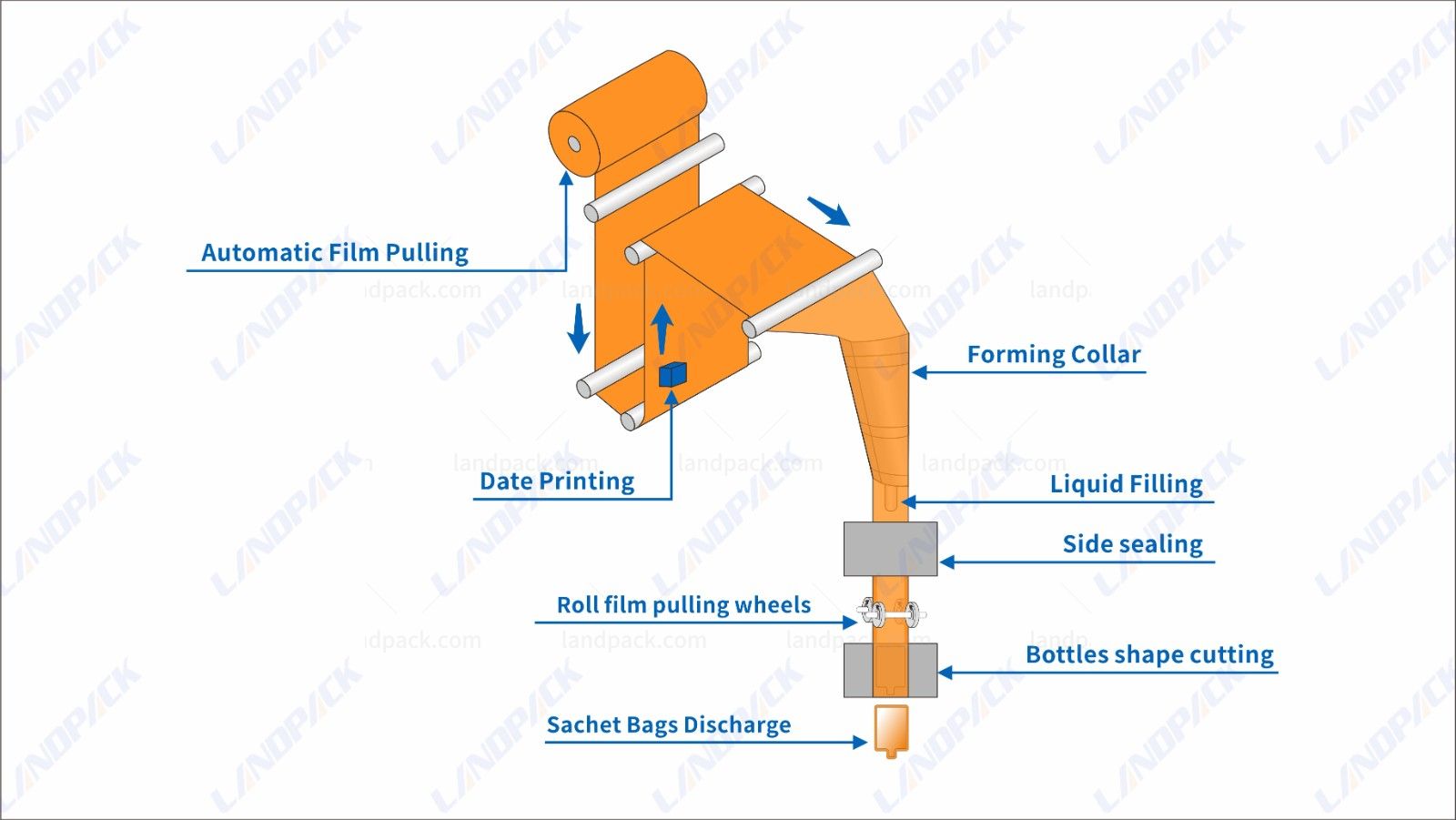

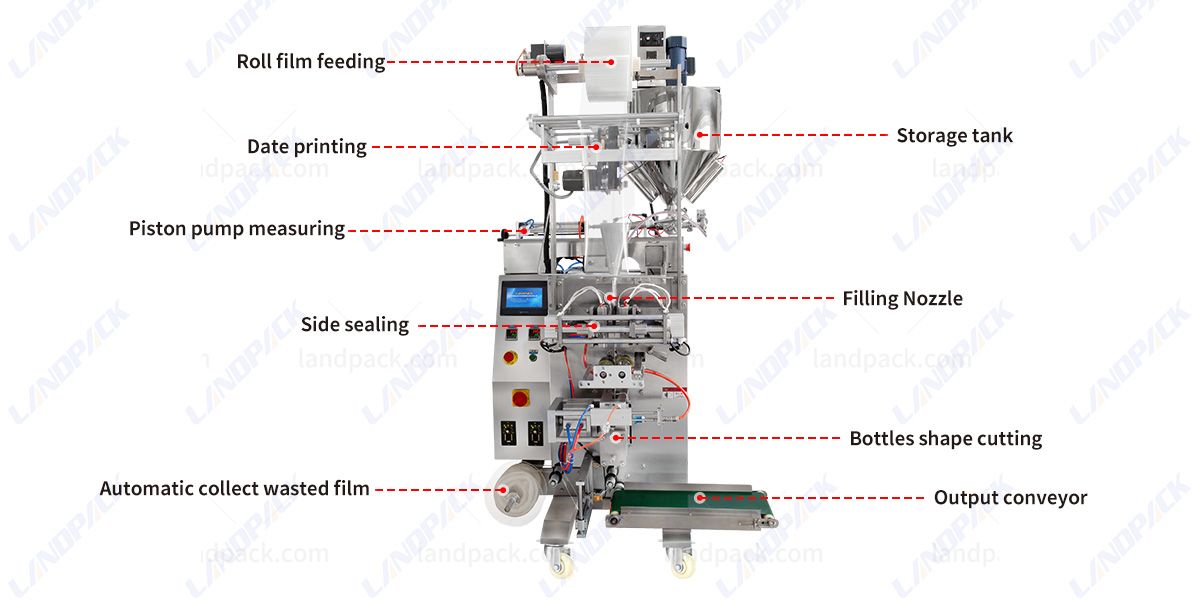

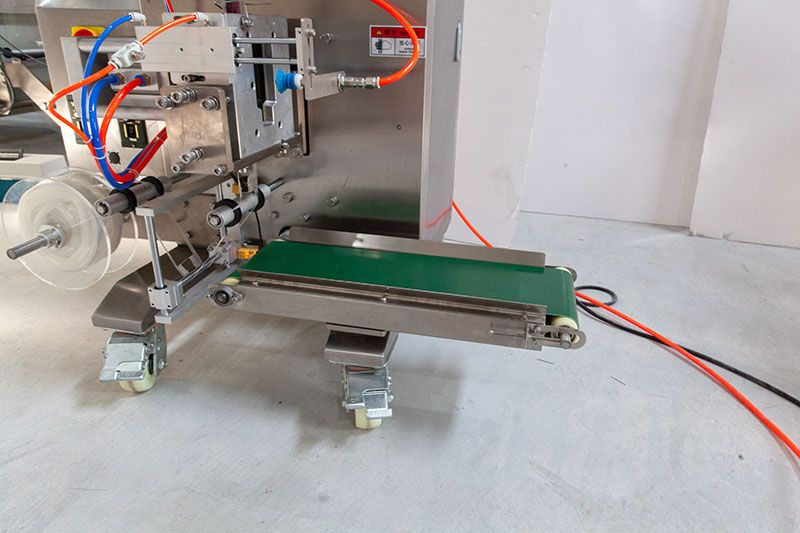

Workflow:

The machine completes the entire bottle-shaped sachet packaging process automatically through the following steps:

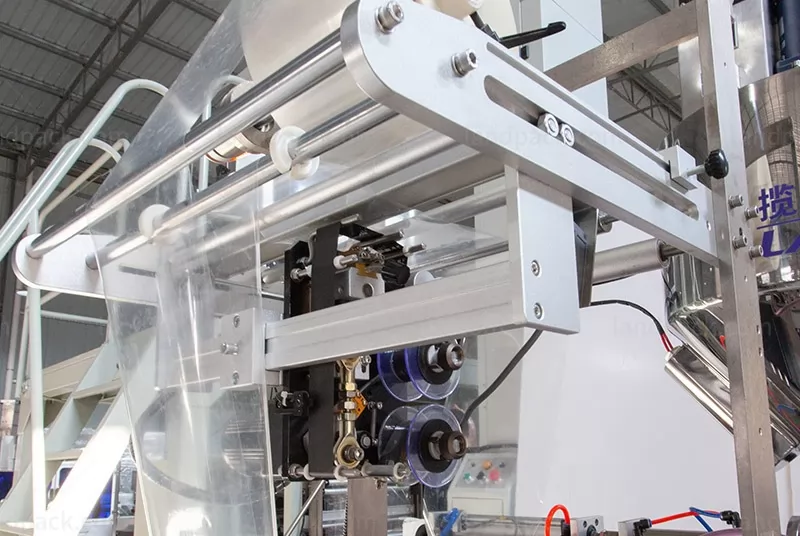

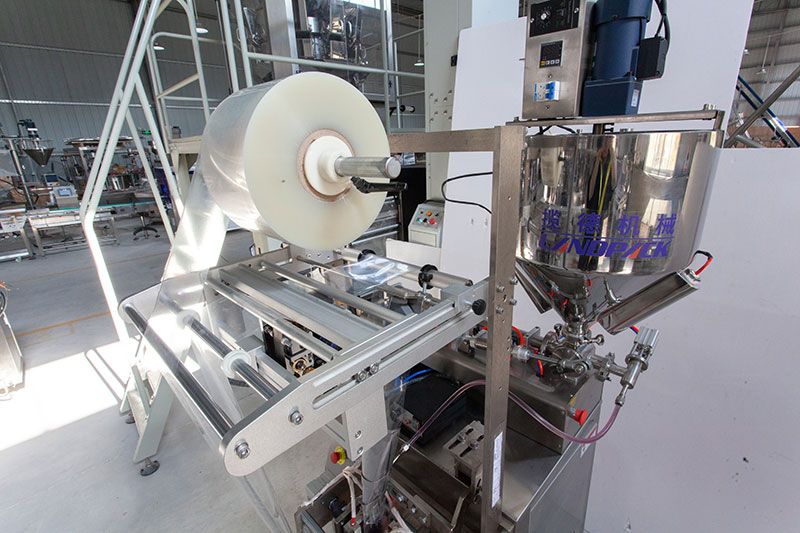

1. Automatic Film Pulling – The film roll is unwound smoothly and then pulled into the form area.

2. Date Printing – The printer marks production dates, batch codes, or other information on the film.

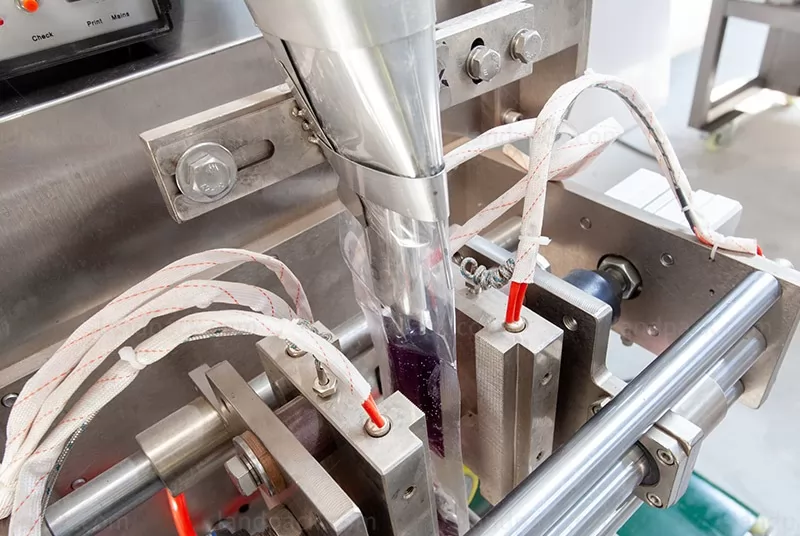

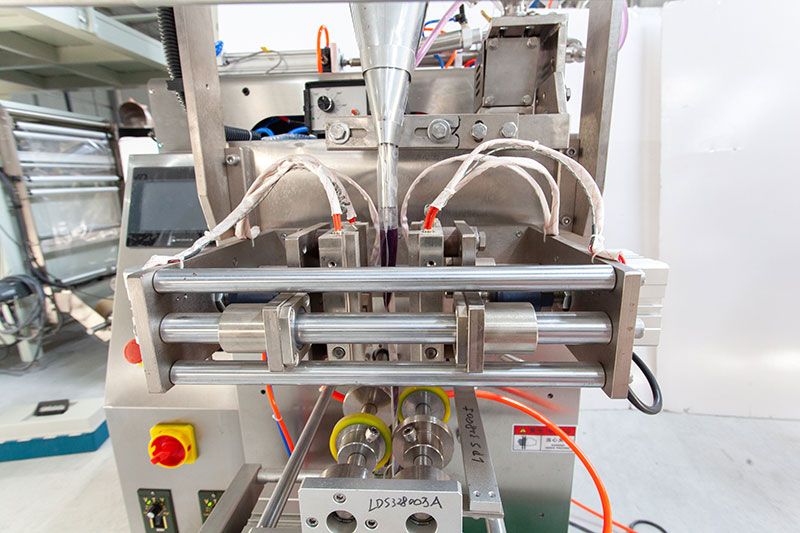

3. Forming Collar – The film passes through the forming collar and is shaped into the bottle-type sachet structure.

4. Liquid Filling – The dosing system precisely fills the required amount of liquid into each pouch.

5. Side Sealing – The side sealing unit applies heat sealing to create strong and secure pouch edges.

6. Roll Film Pulling Wheels – Pulling wheels continuously draw the film downward toward the cutting section.

7. Bottle Shape Cutting – A custom die cuts the film into the unique bottle-shaped outline.

8. Sachet Bags Discharge – Finished shaped sachets are automatically discharged from the machine.