1. Fully Automatic Packaging Process: From filling and bag forming to sealing and date coding, the machine operates fully automatically, significantly reducing labor costs.

2. Unique Irregular Bag Mold: Creates attractive, non-standard bag shapes that enhance product presentation and market appeal.

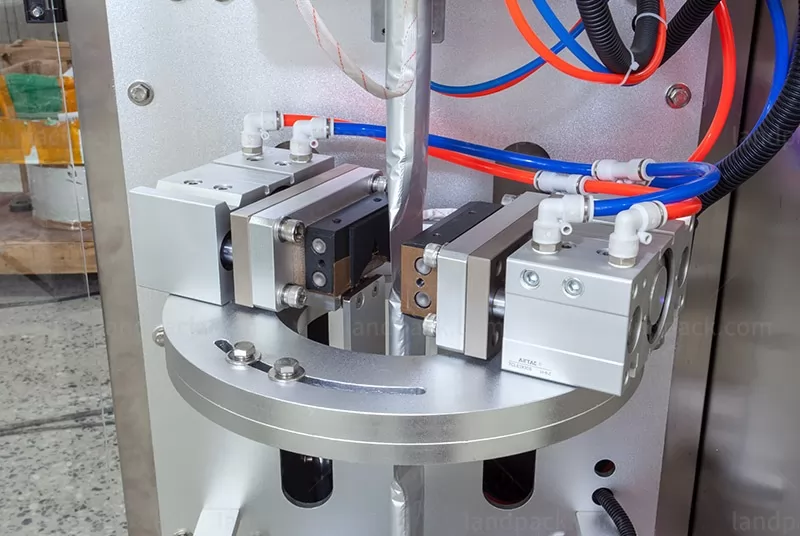

3. Precision Piston Pump Dosing: Utilizes a piston pump system, ideal for filling thick, viscous, or non-free-flowing liquids with high accuracy.

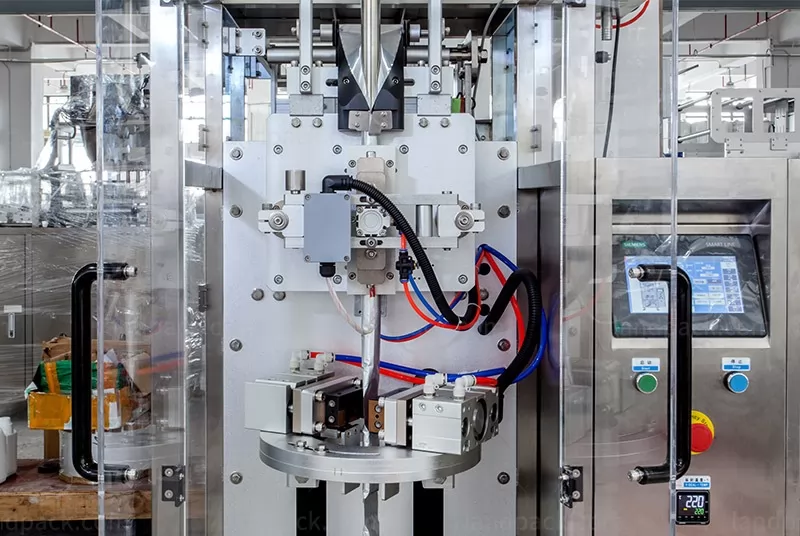

4. Siemens Touch Screen Control: Equipped with a Siemens touch screen for smart, user-friendly interface and flexible parameter setting.

5. High Sealing Quality: Ensures firm, leak-proof seals even for challenging liquids, maintaining hygiene and reducing waste.

6. Durable Stainless Steel Structure: Made with food-grade stainless steel for long-term durability, easy cleaning, and compliance with hygiene standards.

7. Adjustable Filling Volume: Supports a wide range of volume settings, making it versatile for various product packaging needs.

8. Compact Design with Efficient Footprint: Space-saving layout without compromising performance—ideal for small to medium-sized production lines.

Workflow:

1. Heating & stirring hopper

2. Piston pump to measure the weight

3. Filming

4. Coding

5. Bag forming

6. Filling

7. Sealing

8. Customize mold punching