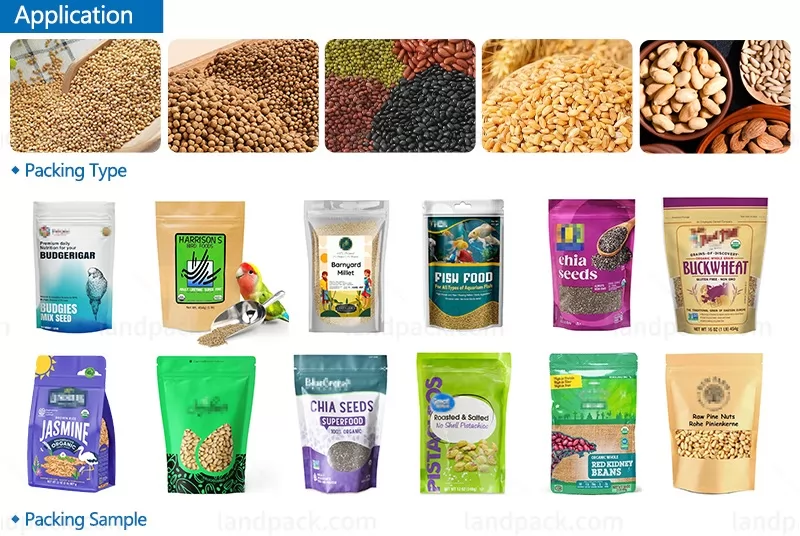

Application:

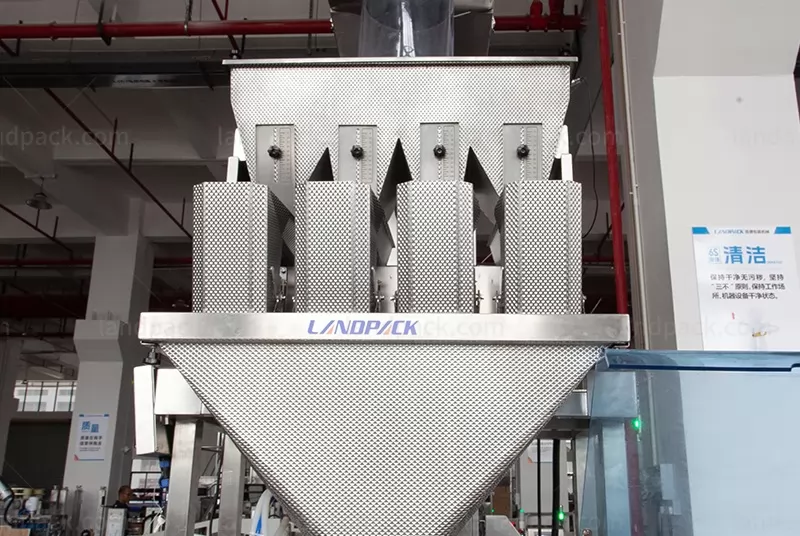

This pet food packing machine is designed for packaging various granular products such as dog food, cat food, fish feed, bird feed, snacks, and pellet materials. Equipped with a high-precision linear weigher, it ensures accurate dosing and stable performance. With a working speed of up to 50 bags/min, it is ideal for automatic granule packing machine production lines, pet food manufacturers, and packaging machine factory operations requiring high efficiency and consistent product quality.

Package Type:

This horizontal pouch packing machine is designed to handle a wide range of pouch formats, ensuring flexibility for different product types and market requirements. It supports the following bag styles: Stand-up Pouch (Doypack), Flat Pouch / 3-Side Seal Pouch, 4-Side Seal Pouch, Zipper Pouch, Pre-made Pouch in various sizes

Suitable Products:

This pet food packing machine is suitable for packaging various granular products such as:

- Food Industry: Snack Foods, Confectionery, Grains & Cereals, Dried Fruits

- Condiment & Ingredient Industry: Seasoning Granules, Salt & Sugar Products, Baking Ingredients, Baking Soda

- Other Granular Products: Pet Food, Health Supplements, Traditional Medicine, Plastic Parts

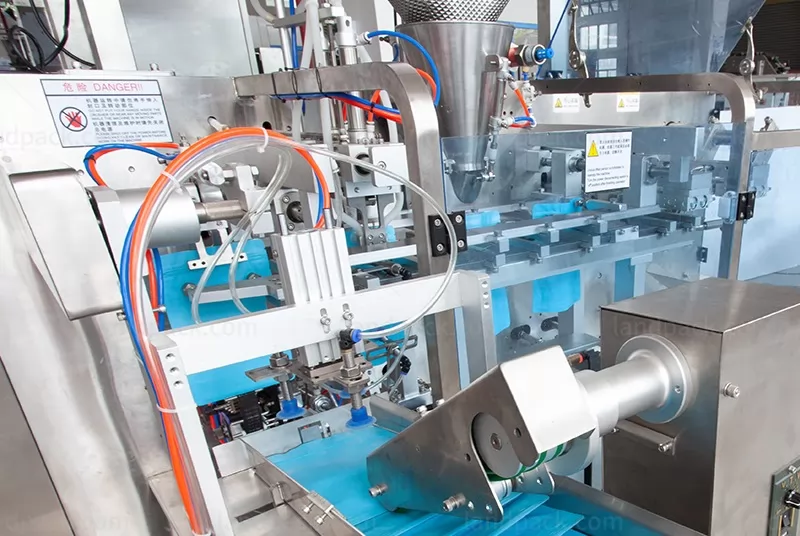

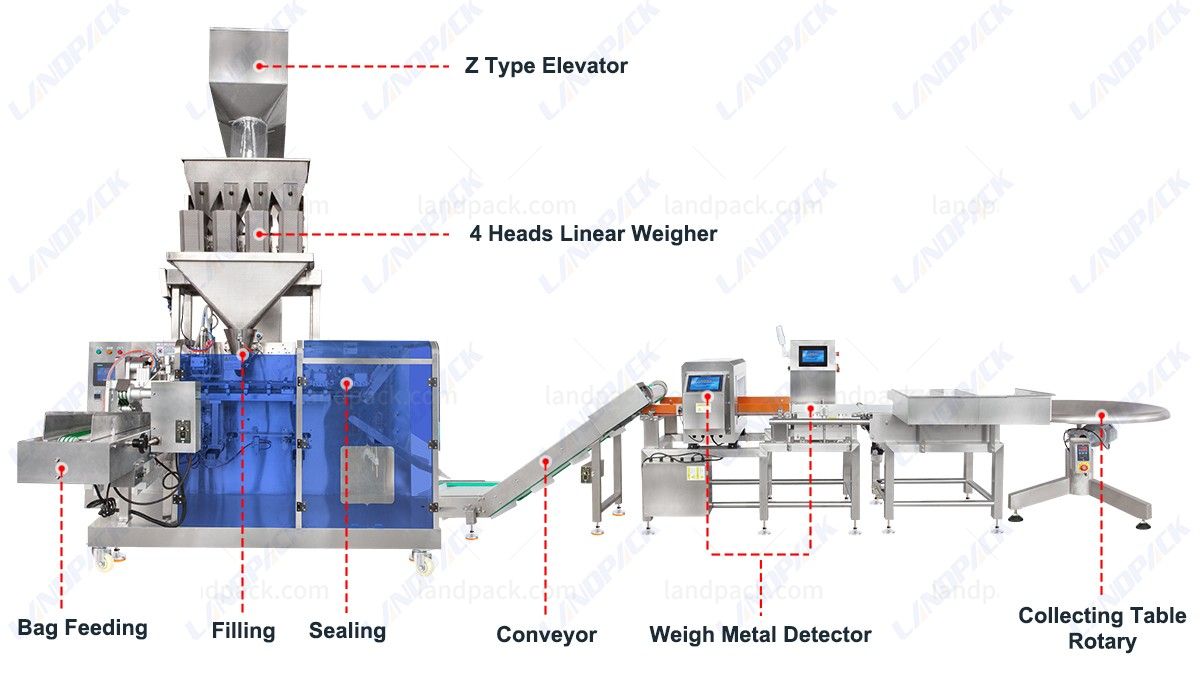

Workflow:

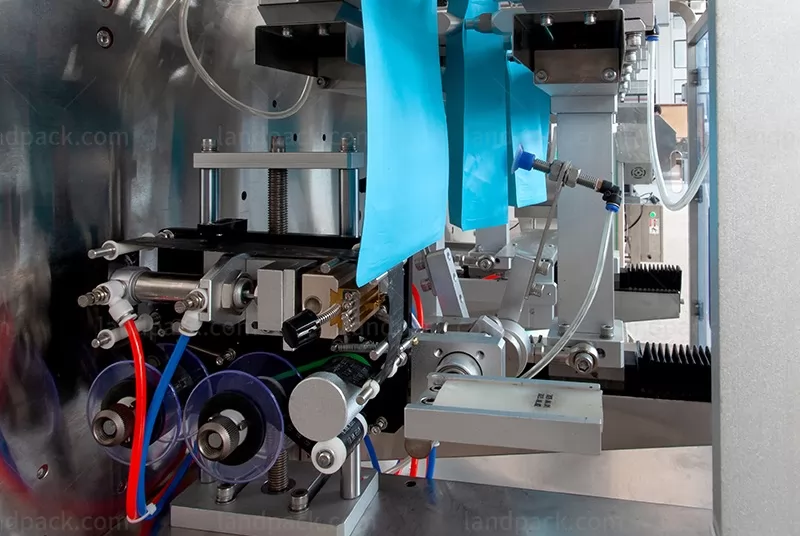

- Bag Feeding: Premade pouches are automatically picked and placed onto the machine for the next steps.

- Date Printing: The system prints production date or batch code accurately on each pouch.

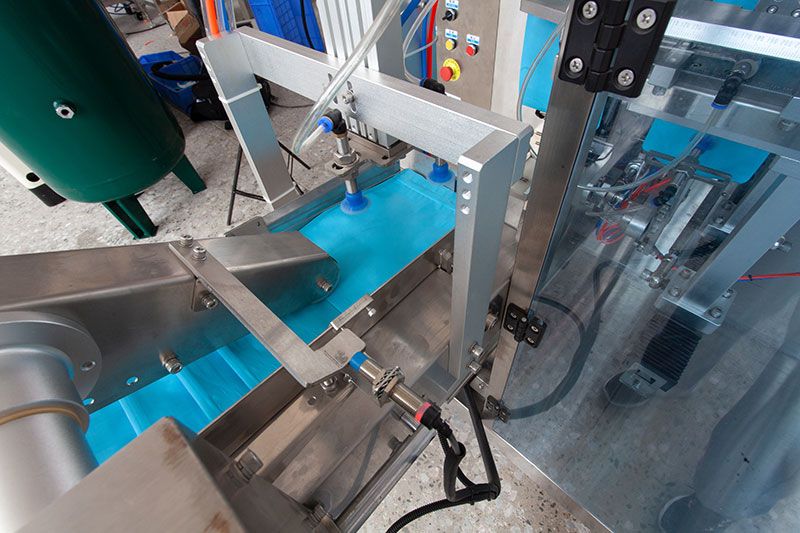

- Bag Opening: Double grippers open the pouch smoothly, ensuring stable filling performance.

- Filling: The linear weigher dispenses pet food or granules in the pouch.

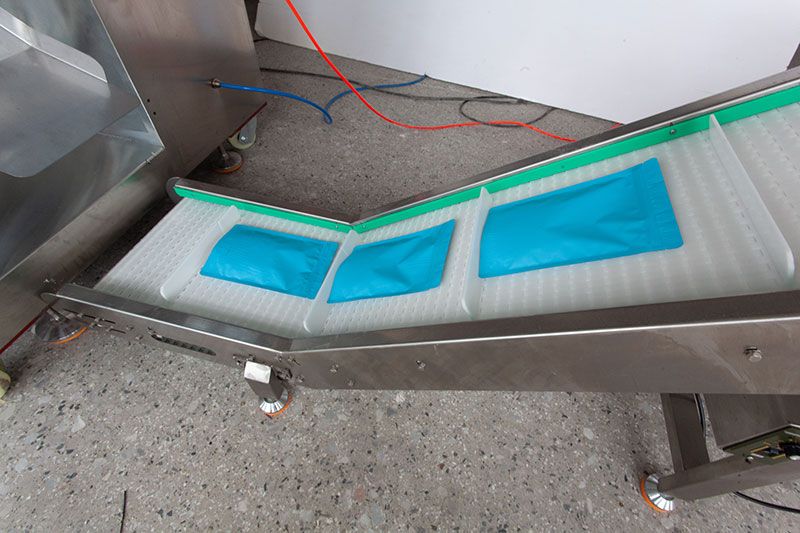

- Sealing: Heat-sealing the pouch ensures freshness and leakproof packaging.

- Output: The finished pouches are neatly discharged to the output conveyor, either for collection or for the next step.