Application:

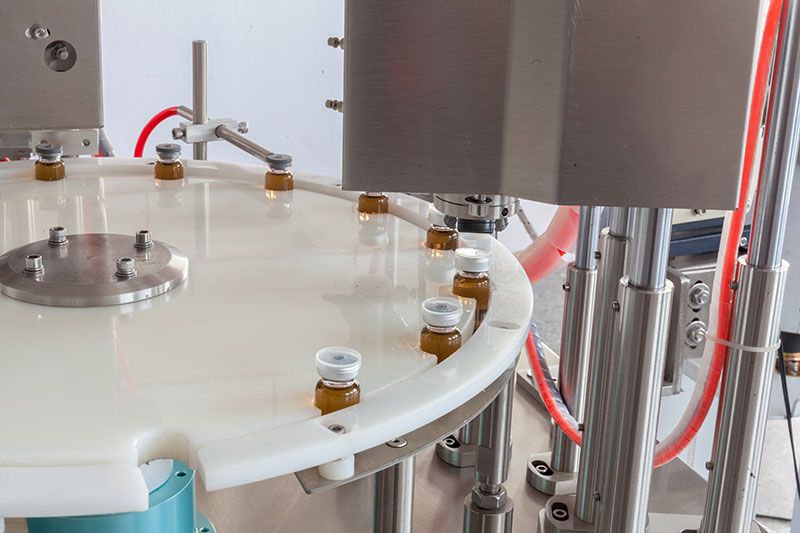

This tabletop vial filling and capping machine can automatically feed bottles, fill liquid into vials, and press bottle caps. It is designed for vials that a conveyor cannot vertically convey; the rotary table fixes the vials and smoothly transports them to the next working station. With a speed of up to 30 bottles/min, it is suitable for various pharmaceutical liquid industries, supporting small to medium-scale production with stable performance and high accuracy.

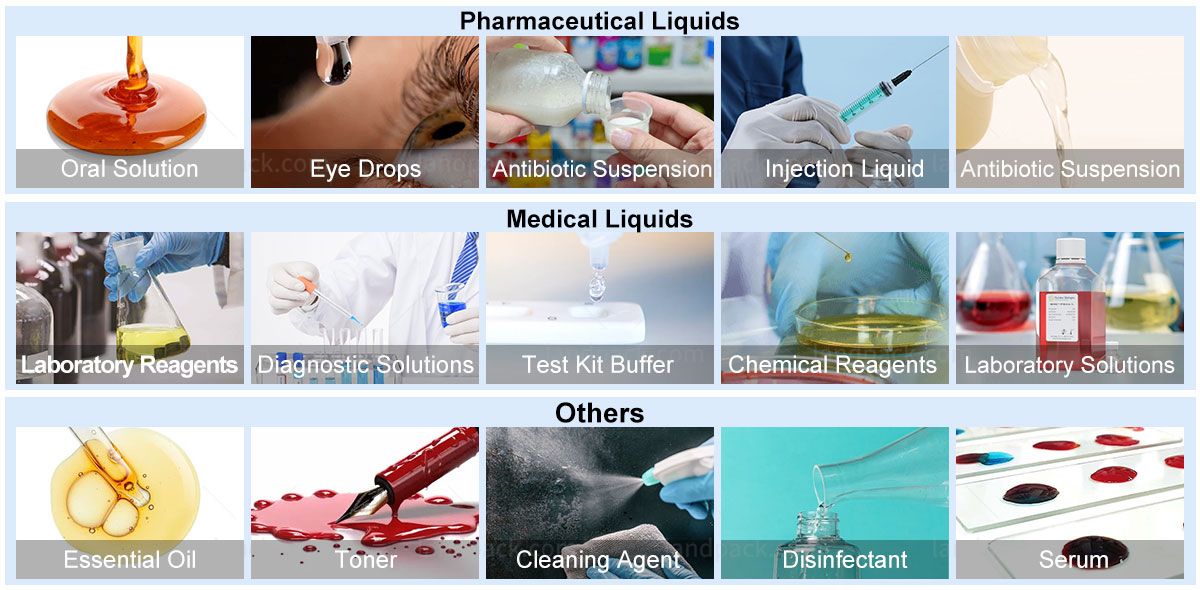

Suitable Products:

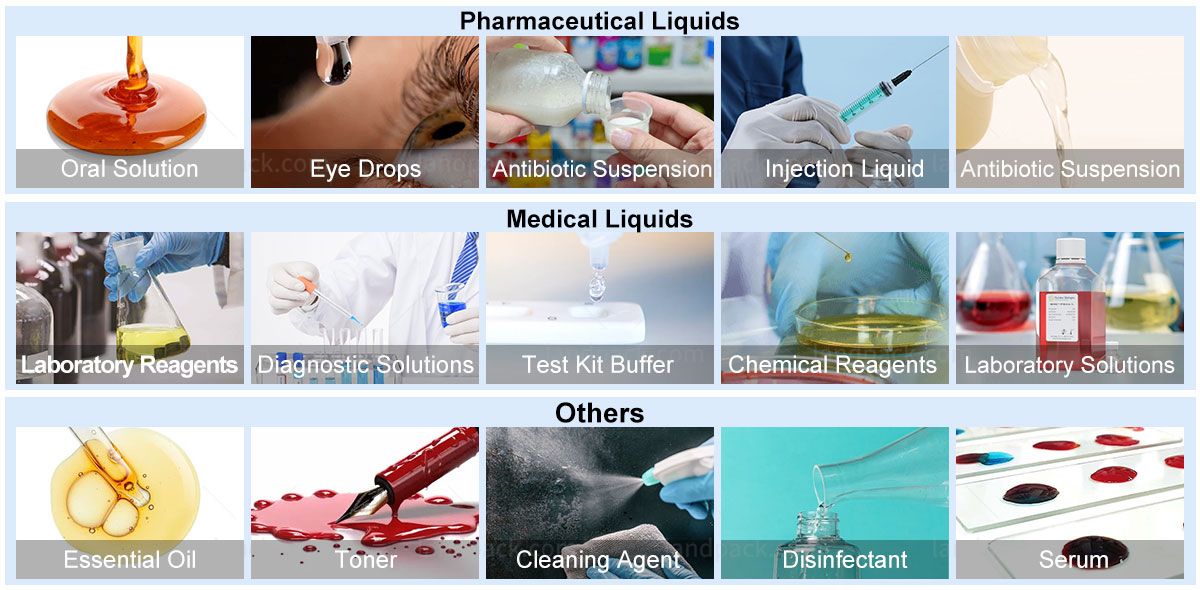

This vial filling and capping machine is versatile across multiple industries.

* Pharmaceutical Liquids: Oral Solution, Eye Drops, Antibiotic Suspension, Injection Liquid, etc.

* Medical Liquids: Laboratory Reagents, Diagnostic Solutions, Test Kit Buffer, Chemical Reagents, Laboratory Solutions, etc.

* Others: Essential Oil, Toner, Cleaning Agent, Disinfectant, Serum, etc.

Container Type:

Our vial liquid filling machine is designed to handle a wide range of vial types, ensuring flexibility for different industries and applications. It is suitable for Glass Vials, Plastic Vials (PET/PP/HDPE), Crimp-Neck Vials, Screw-Cap Vials, Flat-Bottom & Round-Bottom Vials, Small-Volume Micro Vials, etc.

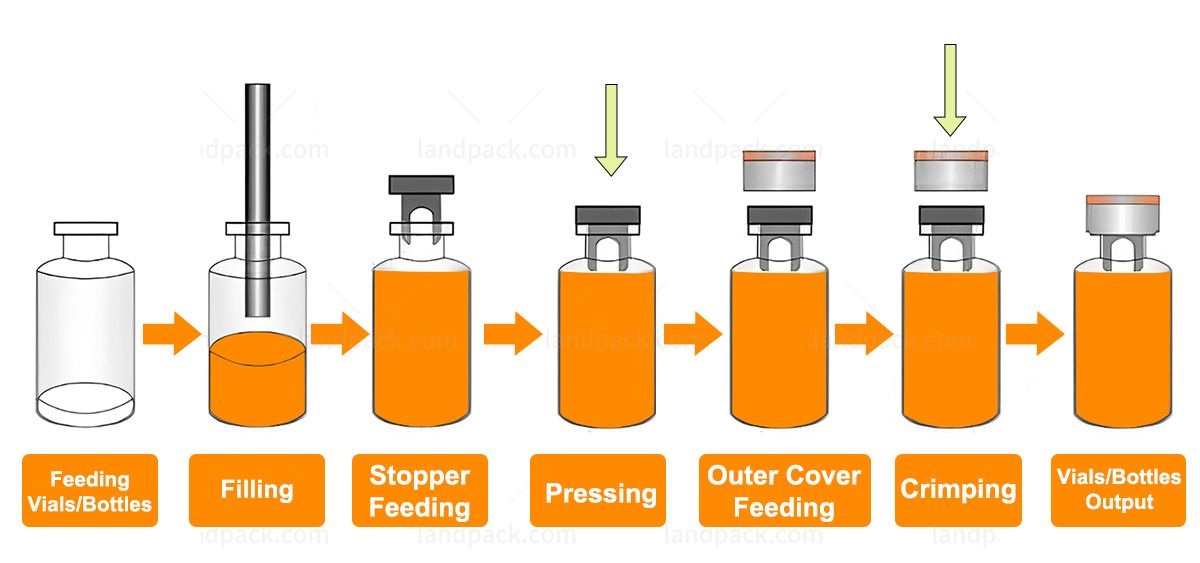

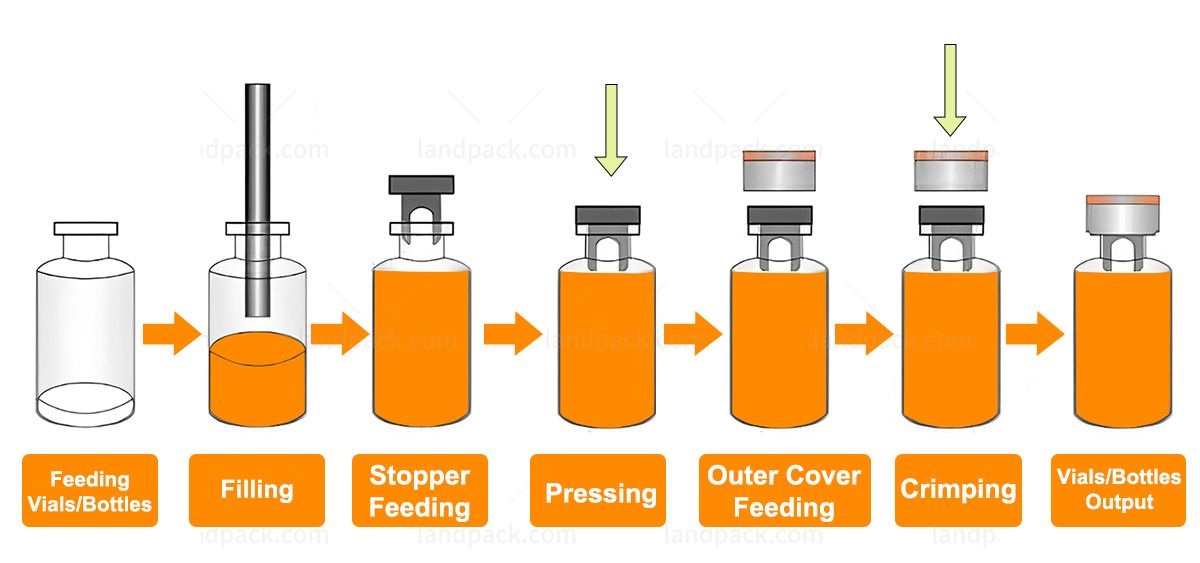

Workflow:

Smart Vial Filling & Capping Process

* Bottle Turntable System – Vials are automatically sorted and fed into the line smoothly, ensuring continuous operation.

* Peristaltic Pump Filling – Single-head filling system delivers accurate and hygienic liquid dosing with minimal waste.

* Inner Cap Automatic Feeding – Inner stoppers are automatically fed and placed into each vial for a secure seal.

* Stopper Pressing System – Ensures stoppers are firmly pressed into place, guaranteeing product safety.

* Outer Cap Automatic Feeding – Outer caps are automatically supplied and placed onto each vial.

* Cap Calibration Device – Aligns and positions caps precisely for consistent quality.

* Cap Crimping System – Securely crimps the outer cap, ensuring a tight and professional seal.

* Finished Bottle Output – Completed vials are smoothly conveyed out, ready for packaging or distribution.