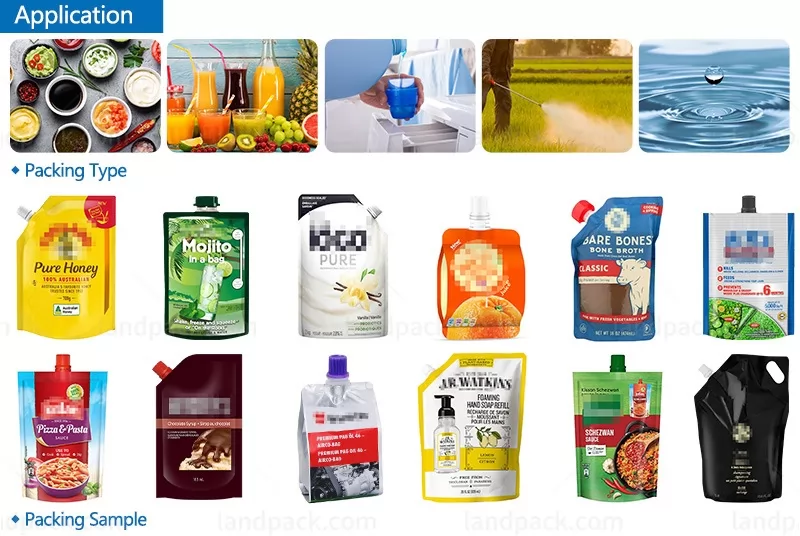

Application:

This 10-head spouted pouch filling and capping machine is fast, clean, and efficient, handling liquids, semi-liquids, and thick pastes. It works with both top and side spout pouches at 80–100 pouches/min, giving accurate fills and tight seals. Perfect for food, drinks, sauces, and daily chemicals, it helps increase output, cut waste, and keep products fresh.

Suitable Products:

This spouted pouch filling machine is versatile across multiple industries.

*Paste products: Ideal for thick and creamy fillings such as peanut butter, chocolate paste, honey, ketchup, and other viscous spreads.

*Juice/Sauce products: Perfect for fluid and semi-viscous sauces, including fruit juice, syrup, chili sauce, oyster sauce, salad dressings, and more.

*Other applications: Widely used for non-food liquids like laundry detergent, disinfectant, pesticide, paint, lubricants, and other chemical solutions.

It ensures clean, precise filling for diverse products while maintaining high-speed production and hygienic standards.

Package Type:

This 10 head filling capping machine compatible with spout pouches featuring either top or side spouts, providing flexible packaging options for various liquid and semi-liquid products.

Workflow:

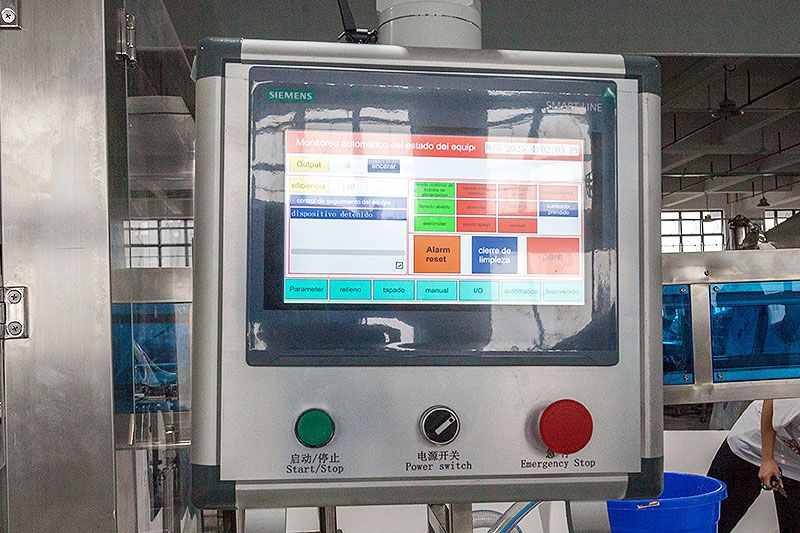

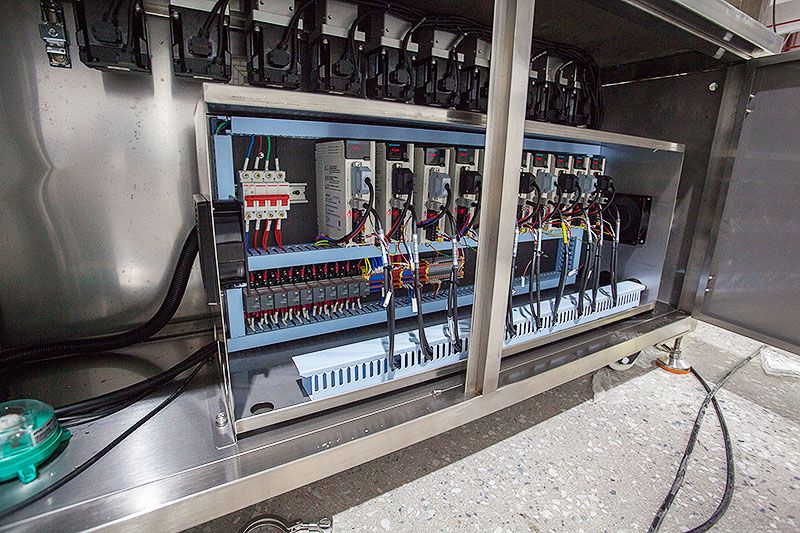

This is a fully automated spout pouch filling capping machine for liquid/paste products in spout pouches. Here's how it works step-by-step:

1. Automatic Bag Feeding Device: Empty spout pouches are automatically fed into the line one by one.

2. Diaphragm Pump Automatic Loading Liquid: Liquid product is pumped automatically from a supply source into the main hopper using a diaphragm pump.

3. 300L Custom-made Feeding Hopper: The liquid/paste is stored in a large, custom-built 300-liter hopper ready for filling.

4. 10 Heads Gear Pump Filling: The product is precisely measured and filled into 10 spout pouches simultaneously using accurate gear pumps.

5. Automatic Cap Lifting and Vibrator Cap Feeding Machine: Caps are handled automatically in two stages:

- Caps are lifted from a bulk supply.

- A vibratory feeder then aligns and feeds the caps individually to the capping stations.

6. 10 Heads Capping: Caps are automatically placed and screwed/tightened onto the 10 filled spout pouches at the same time.

7. Outlet and 3 Meter Finish Pouch Collection Belt: The finished, sealed pouches exit the line onto a 3-meter long collection conveyor belt. This belt transports the finished products for easy boxing or further handling.