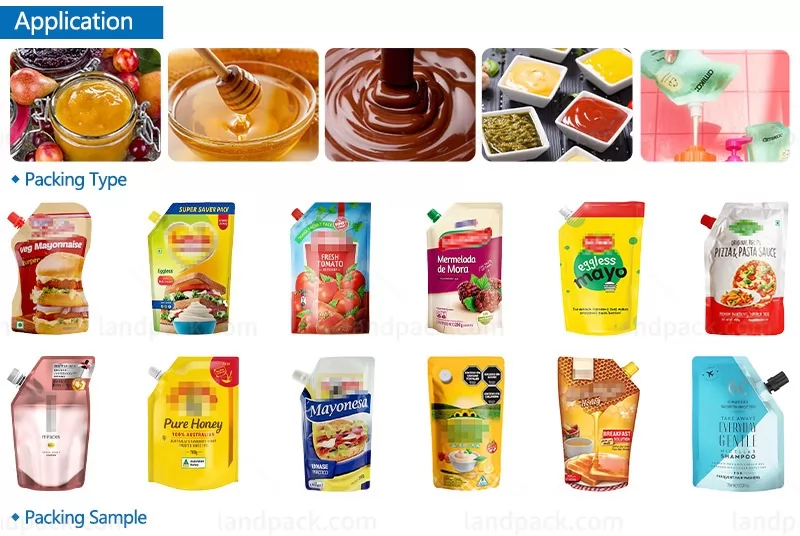

Application:

This pouch filling machine is generally used for filling and sealing stand-up pouch for packaging liquids and semi-liquid products. Suitable for banana sauce, ketchup, juice, jelly, soy milk, yogurt, seasoning, detergent, mineral water, juice, ice cream, edible oil, seasoning, laundry detergent, etc.

Package Type:

This machine supports a wide range of liquid-friendly pouch formats, including spout pouches, flat pouches, and stand-up doypacks designed for sauces, beverages, and personal-care liquids.

Suitable Products:

Built with a high-precision piston pump, this line is designed for smooth, accurate filling of liquids, semi-liquids, and viscous formulations.

- Sauces & Condiments: Tomato paste, chili sauce, salad dressings, honey, syrup, cooking oil, marinades, and other thick or flowable food sauces.

- Beverage & Daily Liquids: Fruit juice, energy drinks, concentrated beverages, flavored water, shampoo, shower gel, hand soap, and other personal-care liquids.

- Industrial & Household Liquids: Detergents, fabric softeners, lubricants, cleaning solutions, cosmetic creams, and chemical liquids compatible with piston-pump dosing.

Workflow:

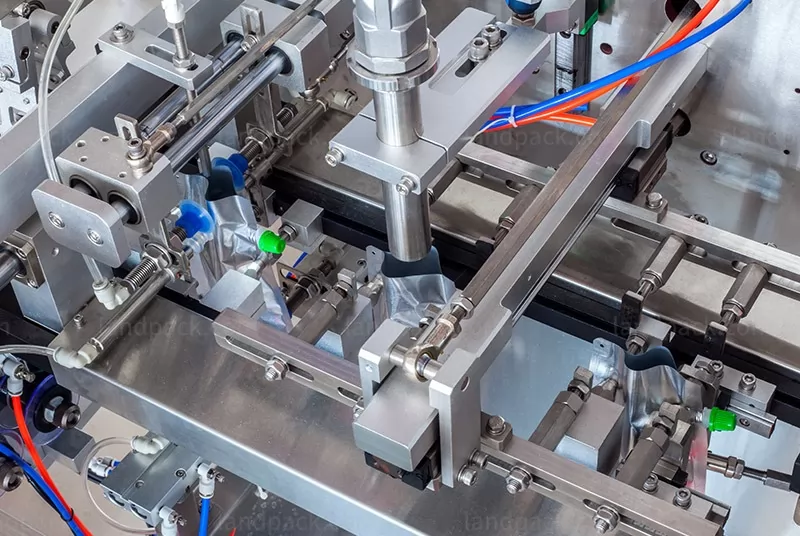

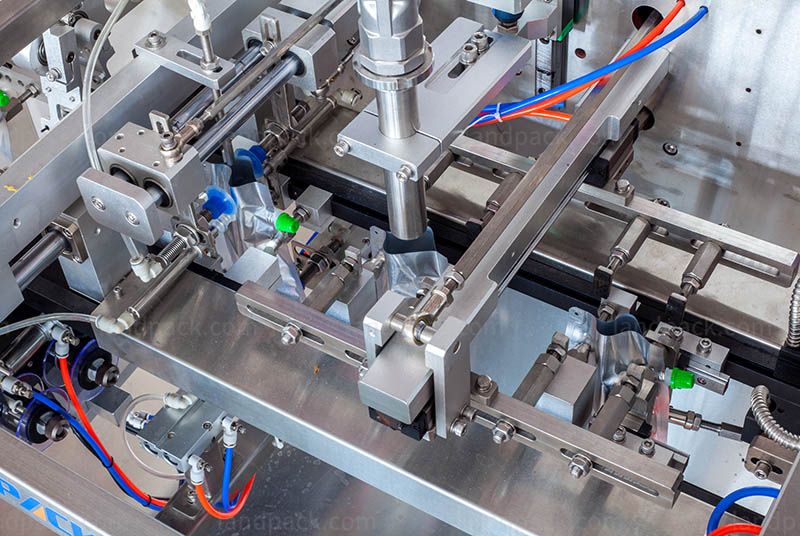

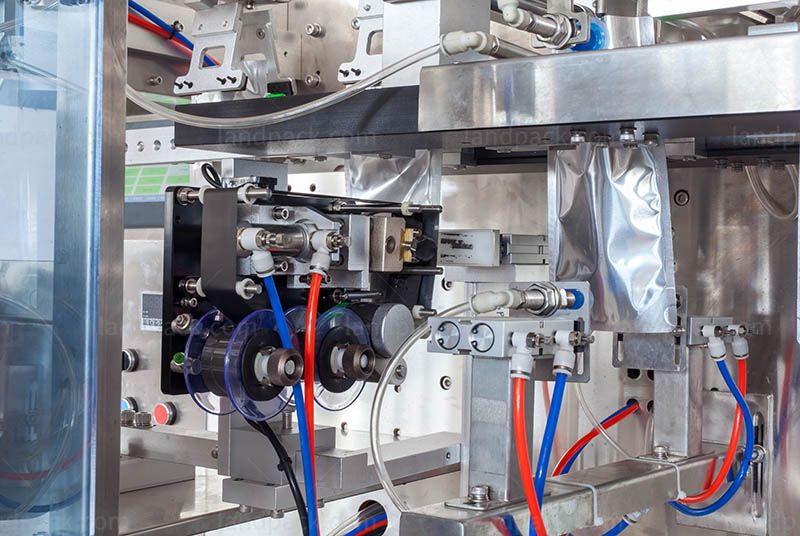

1. Pouch Feeding: Premade pouches are automatically picked from the magazine and placed onto the horizontal conveyor.

2. Coding: Before filling, the coding unit applies clear production dates, batch numbers, or traceability marks onto each pouch.

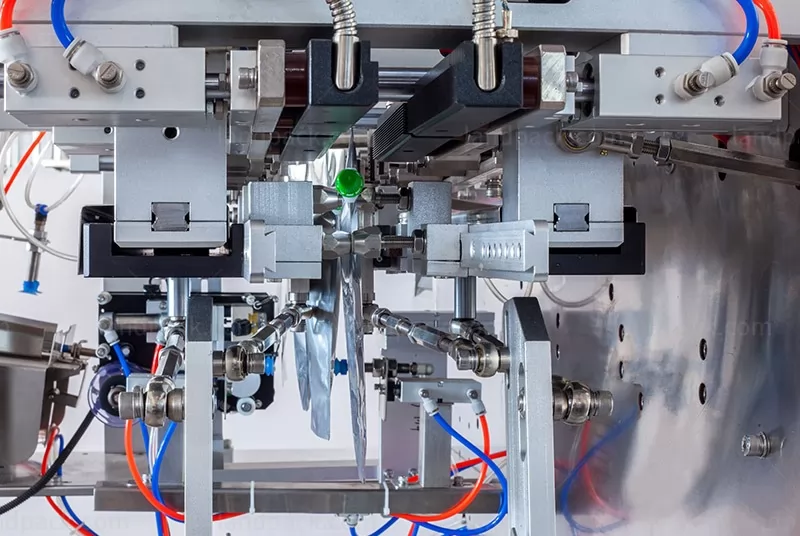

3. Pouch Opening & Detection: Dual suction pads gently open the pouch mouth while sensors confirm successful opening.

4. Precision Piston Dosing: The piston pump draws and dispenses precise volumes of liquid, handling everything from thin juices to thick sauces.

5. Nozzle Filling Process: The filling nozzle moves smoothly into position to reduce splashing and avoid product contact with the sealing area.

6. Sealing: The sealing jaws apply controlled heat and pressure to form a firm, leak-proof seal.

7. Finished Pouch Discharge: Completed pouches are released onto the output conveyor.