Application:

This automatic spout pouch filling machine is fast, clean, and efficient, designed for liquids, semi-liquids, and thick pastes. It works with side spout pouches at a speed of 50 pouches/min, ensuring accurate filling and reliable sealing. Ideal for food, beverages, sauces, and daily chemical products, it helps boost productivity, reduce waste, and keep products fresh.

Suitable Products:

This automatic spout pouch filling machine is versatile across multiple liquid industries.

* Food: Widely used for food liquids like juice, soy sauce, ketchup, peanut butter, etc.

* Daily Chemicals: Ideal for shampoo, hand soap, laundry detergent, lotion, etc.

* Medical: Perfect for fluid and semi-viscous liquids like antiseptic liquid, syrup, nutrient solution, oral liquid, etc.

Package Type:

This automatic spout pouch filling machine compatible with spout pouches, stand up pouches, flat pouches, providing flexible packaging options for various liquid and semi-liquid products.

Workflow:

This is automatic spout pouch filling machine for liquid/paste products in spout pouches. Here's how it works step-by-step:

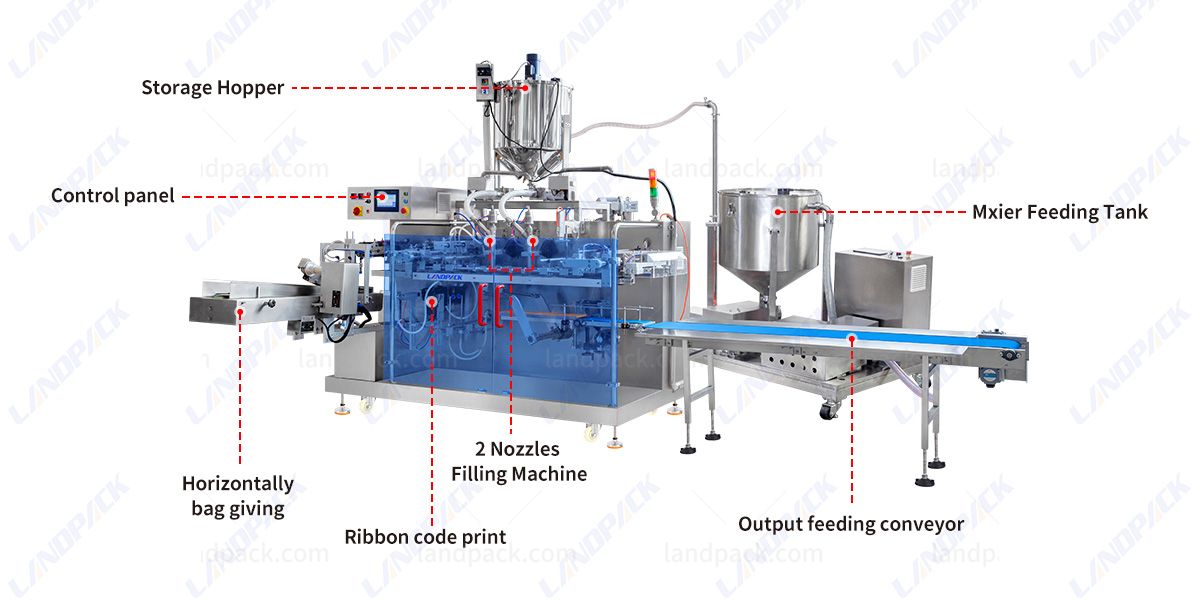

1. Mixer Feeding Tank – The product is evenly mixed and transferred into the system, ensuring stable quality.

2. Automatic Empty Pouch Feeding Device – Pouches are automatically placed, saving time and labor.

3. Bag Opening Device – Each pouch is precisely opened, ready for filling.

4. 2 Nozzles Filling Machine – Dual nozzles work simultaneously for faster speed and stable performance.

5. Automatic Nitrogen Filling Device – Extends shelf life and keeps products fresh by flushing out oxygen.

6. Double Sealing Station – Ensures tight, secure, and durable seals for perfect packaging.