Application:

The spout pouch packing machine is suitable for a broad range of product—including ketchup, chili sauce, soy sauce, curry paste, salad dressing, honey, fruit purée, dessert sauce, and condiment blends—as well as non-food viscous products such as detergent gel, cosmetic creams, and household cleaning pastes.

Package Type:

This machine is compatible with a wide range of premade pouch types, including stand-up pouches, zipper pouches, spout pouches, and premade pouches, allowing manufacturers to choose the most suitable style for product presentation and shelf display.

Suitable Products:

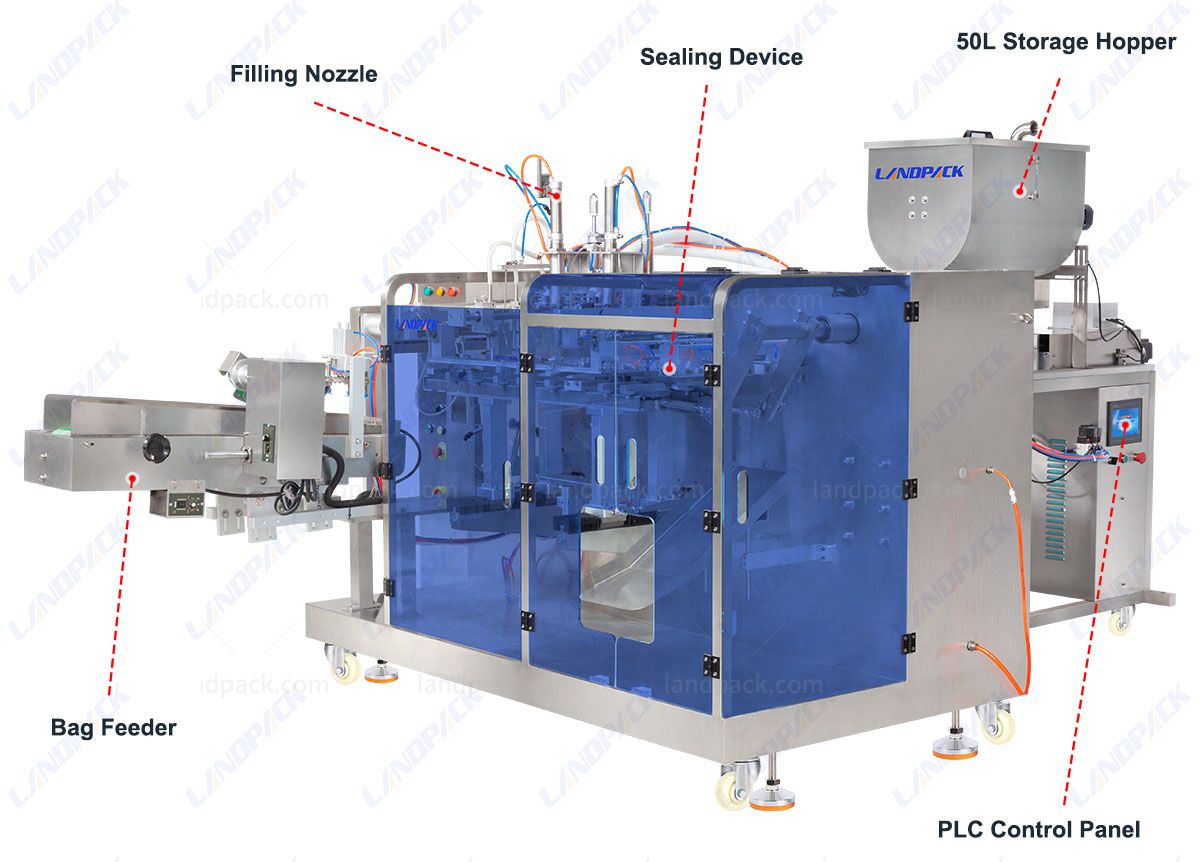

The spout pouch packing machine, equipped with dual filling nozzles and a 50L U-shaped hopper, is designed for efficient, clean, and precise packaging of viscous and semi-liquid products. It is widely used across multiple industries, including

- Sauces & Condiments: ketchup, chili paste, tomato sauce, salad dressing, mayonnaise.

- Liquid Foods: honey, syrups, fruit jam, concentrated juice), Ready-to-Eat Meal.

- Personal Care Liquids: shampoo, shower gel, liquid soap.

Workflow:

1. Pouch Feeding: The machine automatically picks and transfers premade pouches from the pouch magazine to the running stations.

2. Date Coding: The printer marks production dates or batch numbers onto the pouch before filling begins.

3. Pouch Opening & Detection: The grippers open the pouch while sensors verify proper opening to ensure safe and accurate filling.

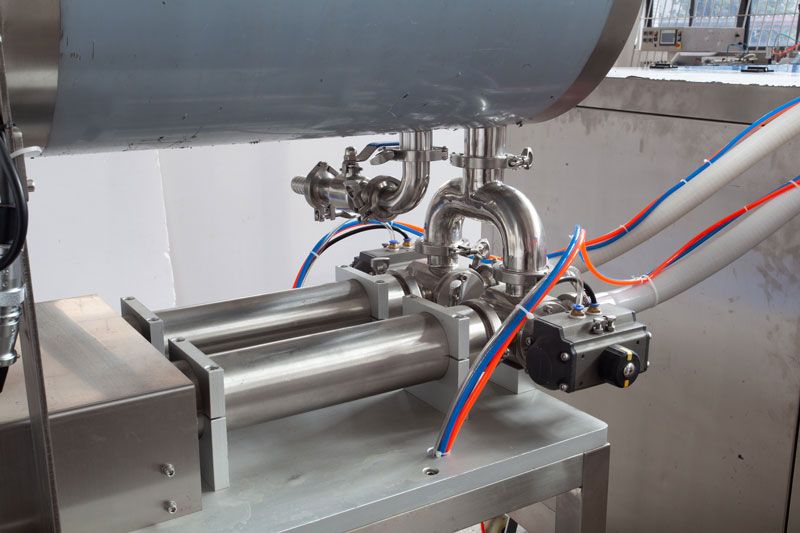

4. Precision Piston Dosing: The piston pump draws and dispenses precise volumes of liquid, handling everything from thin juices to thick sauces.

5. Dual-Nozzle Filling: Two servo-controlled filling nozzles inject the liquid or sauce simultaneously.

6. Air-Blow Drip Prevention: A built-in air-blowing function clears residue from the nozzles to prevent dripping and keep pouch mouths clean.

7. Double Heat Sealing: The pouch is sealed twice—primary and secondary sealing

7. Cooling & Discharge: The sealed pouch is cooled and then conveyed to the output belt for collection and packing.