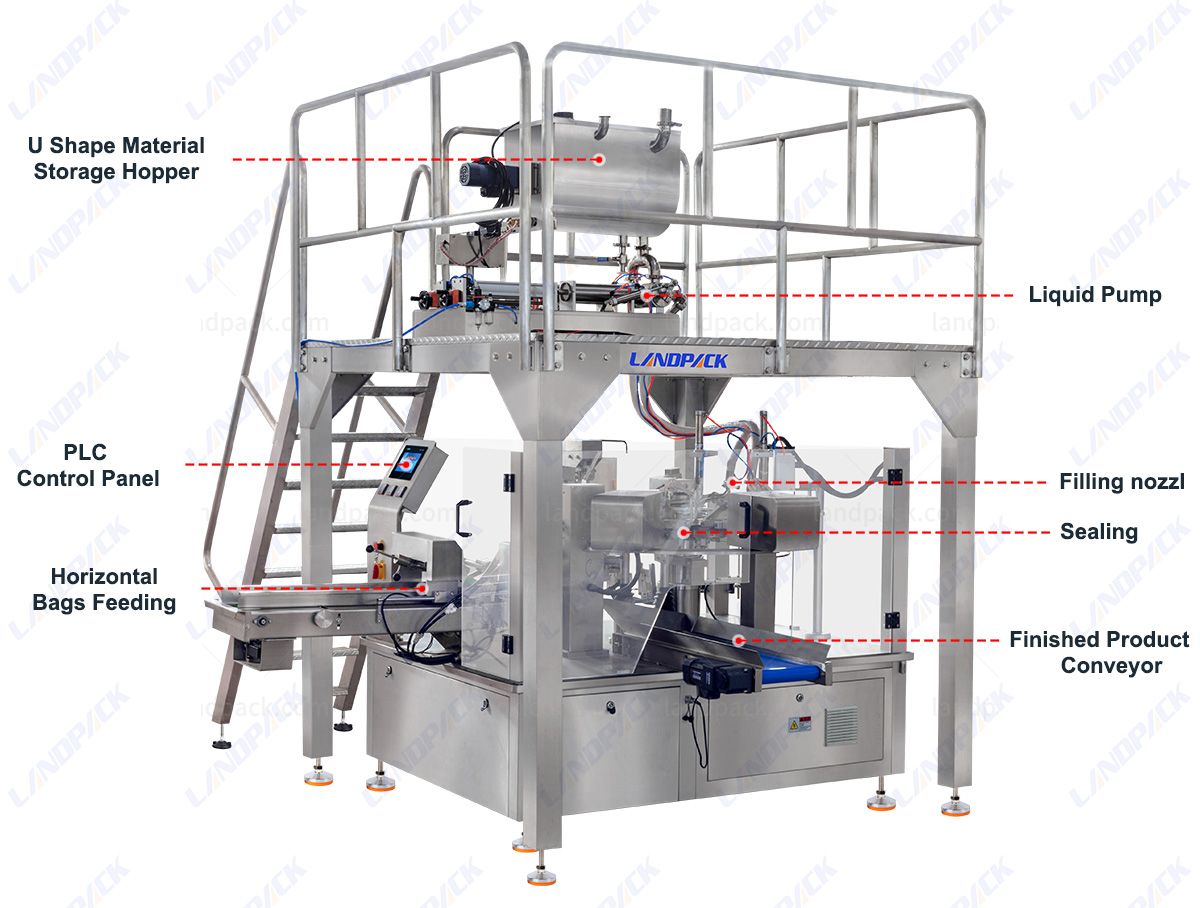

Application:

This Spout Pouch Filling Machine is widely used for various liquid and semi-liquid products, including juice, energy drinks, edible oil, condiments, sauces, detergents, shampoo, cosmetics, and household chemicals. It is ideal for industries requiring hygienic, leak-proof, and high-speed premade spout pouch packaging.

Package Type:

Compatible with a wide range of premade flexible pouches, including corner-spouted pouches, stand-up pouches, doypack bags, flat-bottom pouches, and other premade laminated bags designed for liquid or semi-liquid products.

Suitable Products:

This pouch filling machine works for a range of jams, sauces and viscous liquids. It ensures safe, precise, and efficient filling of manufacturers of condiments and food products.

- Sauces: Mayonnaise, Barbecue Sauce, Ketchup, Chili Sauce

- Jams: Strawberry Jam, Mango Jam, Blueberry Jam, Marmalade

- Viscous Foods: Chocolate Sauce, Peanut Butter, Honey Paste, Garlic Paste

Workflow:

This is automatic spout pouch filling machine for liquid/paste products. Here's how it works step-by-step:

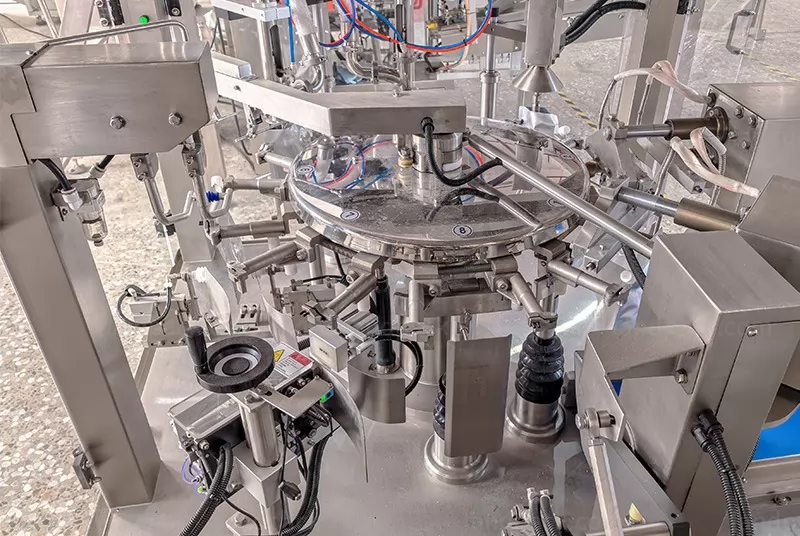

1. Bag Feeding – The gripper automatically picks up premade pouches and places them onto the rotary station.

2. Date Coding – Inkjet or hot stamp coding is applied to the pouch.

3. Bag Opening – Vacuum suction as well as mechanical clamps work in tandem to allow the pouch mouth to be opened safely.

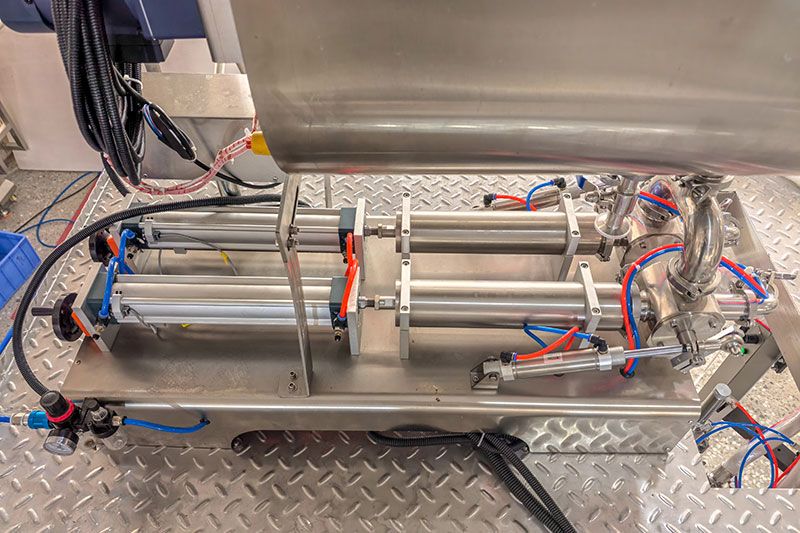

4. Liquid Filling – The filling nozzle precisely doses sauces, liquids or viscous items in the bag.

5. Bag Mouth Cleaning – The mouth of the pouch is cleaned to get rid of any residues of the product before sealing.

6. First Heat Sealing – The pouch is given the first heat seal in order to close the spout.

7. Second Heat Sealing – A strengthened sealing procedure ensures sturdy pouch seals that are leak-proof.

8. Finished Product Discharge – Completed pouches are automatically discharged on the conveyor for packing downstream.