Application:

This automatic cartoning machine is suitable for packing a wide range of products such as blister packs, facial masks, data cables and glue sticks, as well as daily-use items like ointment tubes, cream jars, batteries and stationery sets.

Package Type:

Engineered for high-efficiency boxing and case packing, this system is compatible with an extensive array of paperboard formats, such as standard folding cartons, corrugated shipping containers, and retail-ready boxes.

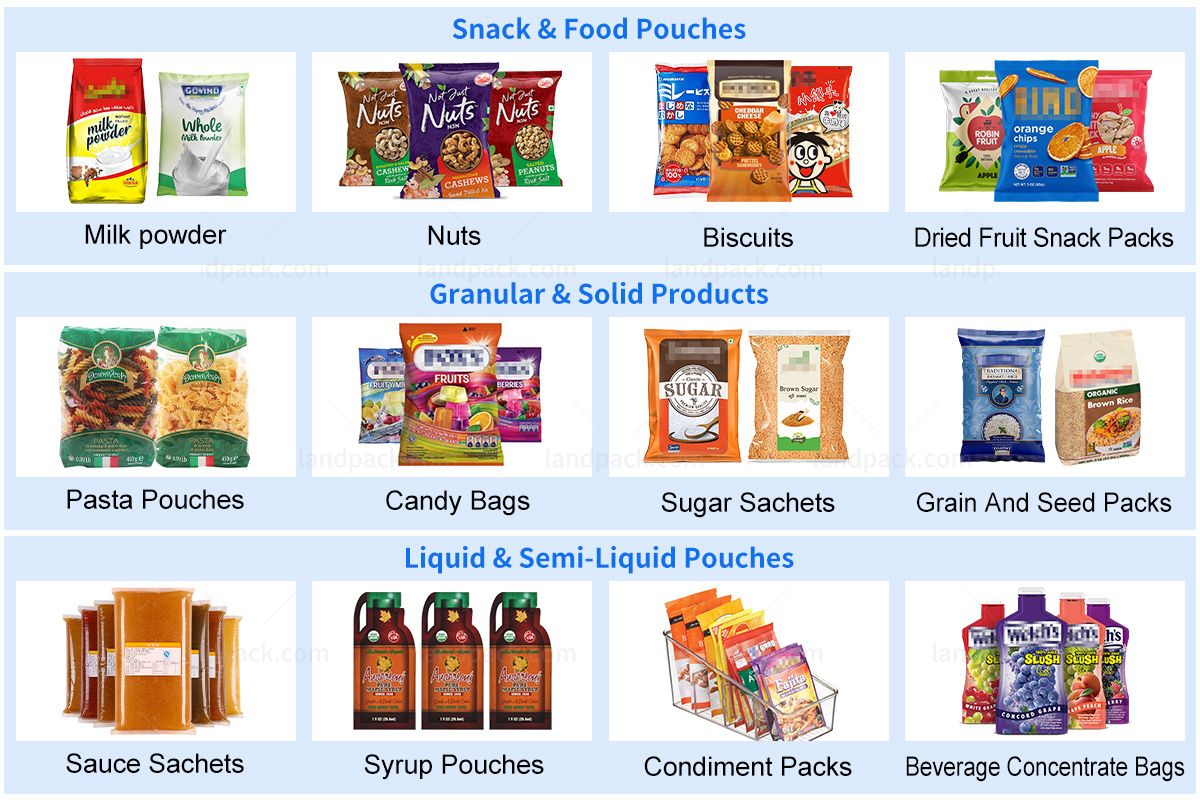

Suitable Products:

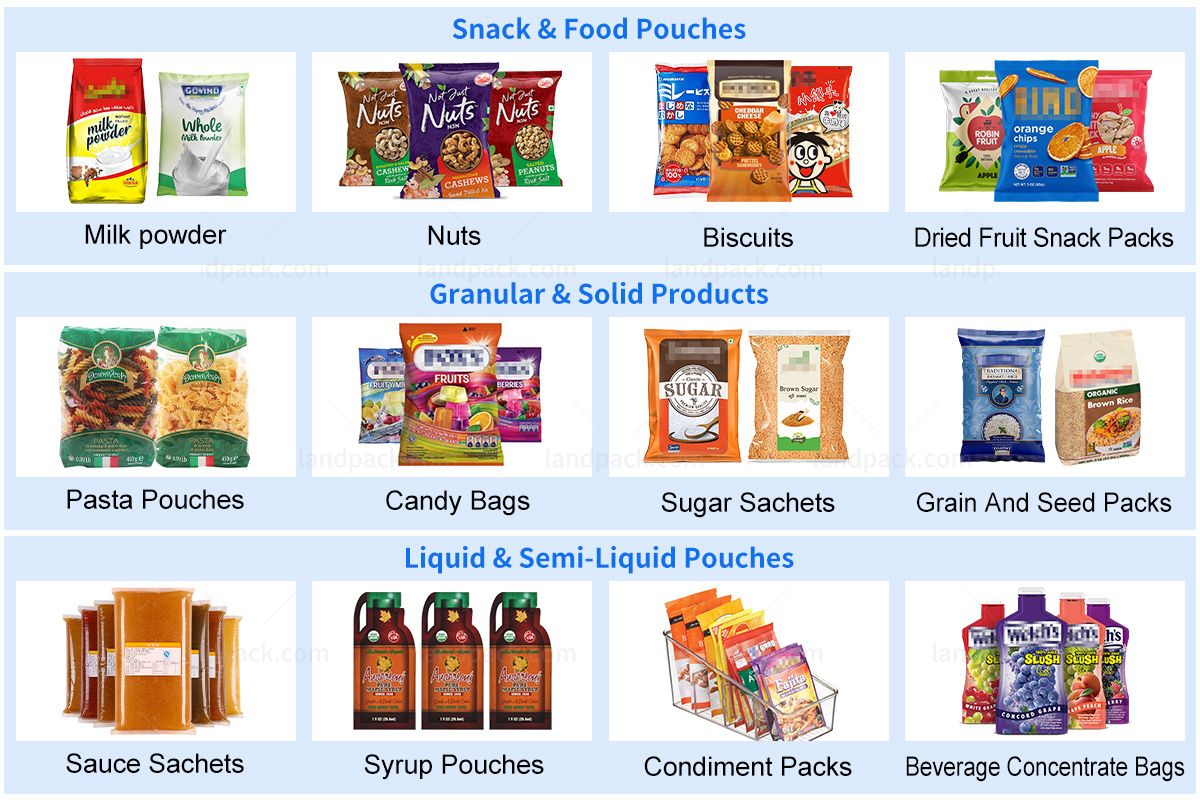

This horizontal cartoning machine features stable product collation, precise infeed positioning, and smooth carton forming and sealing. It is widely applied across multiple product categories, including

Food products: milk powder, nuts, biscuits and dried fruit snack packs

Granular & solid products: pasta pouches, candy bags, sugar sachets and grain packs

Liquid & semi-liquid items: sauce sachets, syrup pouches, condiment packs and beverage concentrate bags.

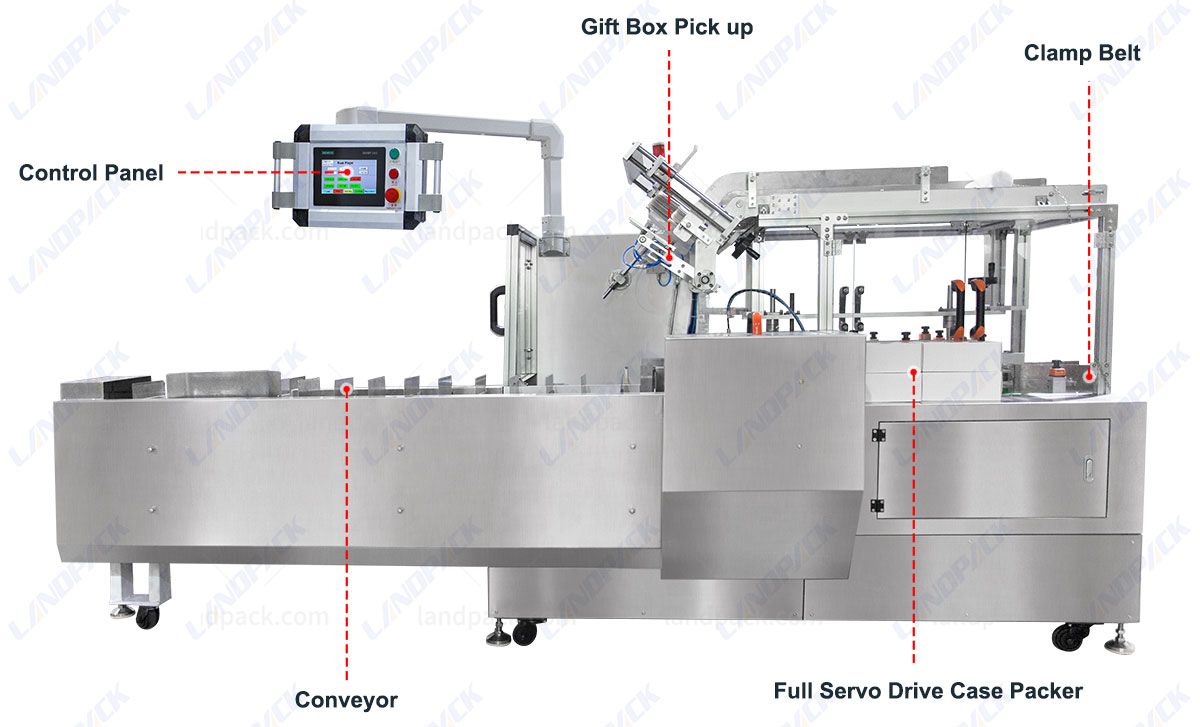

Workflow:

1. Product Infeed: Completed items are transported from the preceding stage in a systematic and organized sequence.

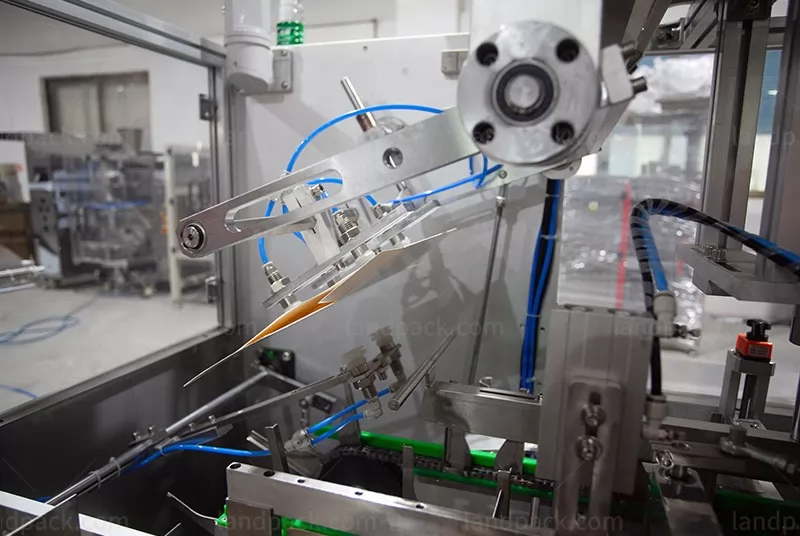

2. Carton Erecting: Flat-packed cartons are automatically retrieved, expanded, and securely aligned for the loading phase.

3. Product Loading: Pre-collated products are transitioned gently into the pre-formed boxes through a smooth pushing mechanism.

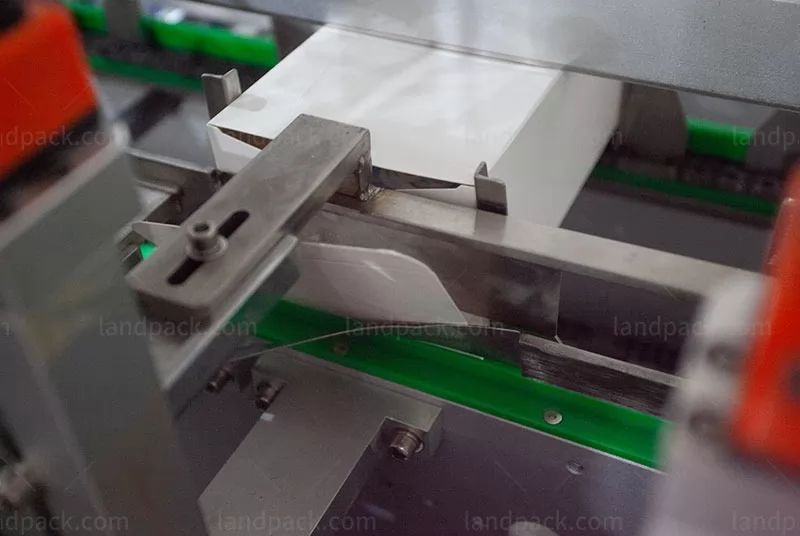

4. Carton Closing & Sealing: The carton flaps are folded and secured to create a clean, professionally finished package.

5. Finished Carton Output: Closed boxes are exited from the machine, ready for subsequent secondary packing, robotic palletizing, or warehouse placement