Application:

The horizontal cartoning machine is designed for efficient secondary packaging at a speed of 30–50 cartons/min. It automatically performs carton erecting, product grouping, horizontal end loading, and carton closing, and is ideal for packaging a variety of products such as pouches, sachets, stick packs, and wrapped items. This machine is widely used in industries including food, pharmaceuticals, cosmetics, daily chemicals, and consumer goods. It can operate independently or be integrated with packing and filling machines to form a fully automated packaging line.

Package Type:

This cartoning machine handles a variety of pre-glued cartons, including tuck-in flap, straight-tuck, and reverse-tuck styles, making it ideal for both retail-ready and protective secondary packaging needs.

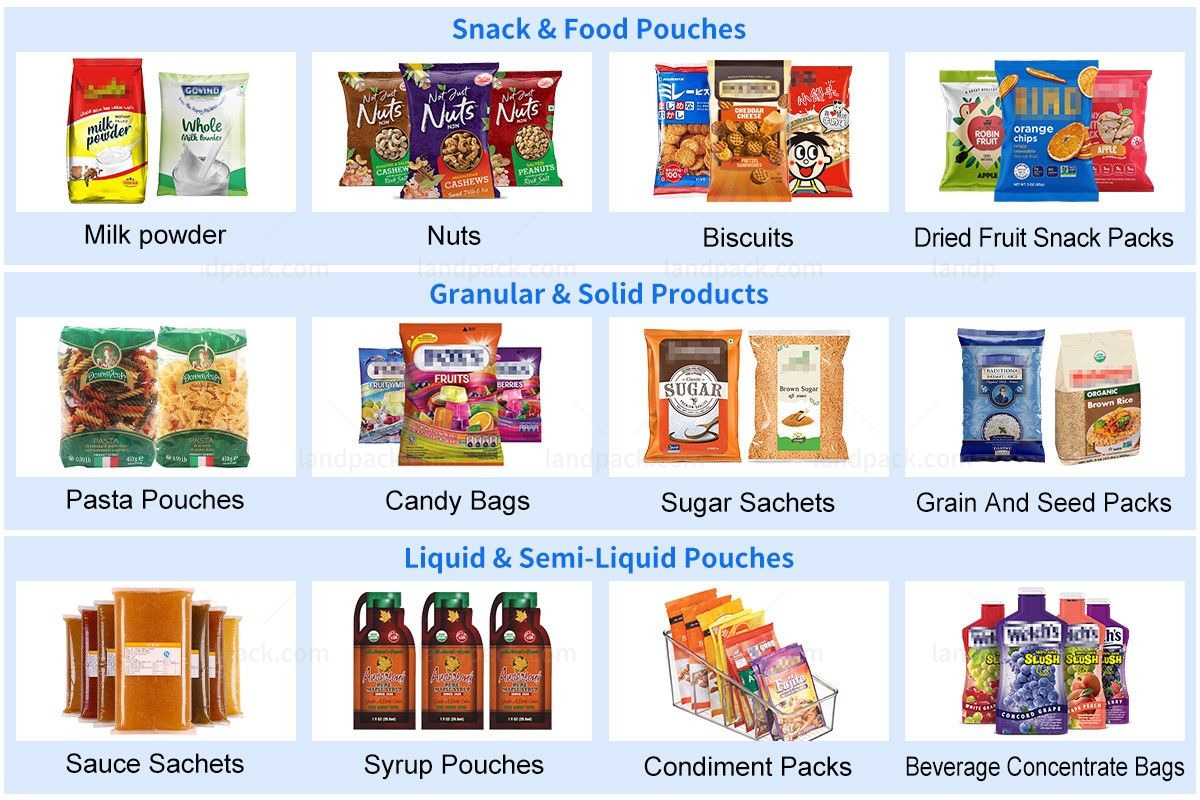

Suitable Products:

The Horizontal Cartoning Machine is designed for a wide range of industries, including food, beverage, pharmaceuticals, cosmetics, daily chemicals, and consumer goods. It efficiently packs a variety of products, such as bags, sachets, sticks, pouches, and pre-wrapped items into boxes for retail-ready or secondary packaging solutions.

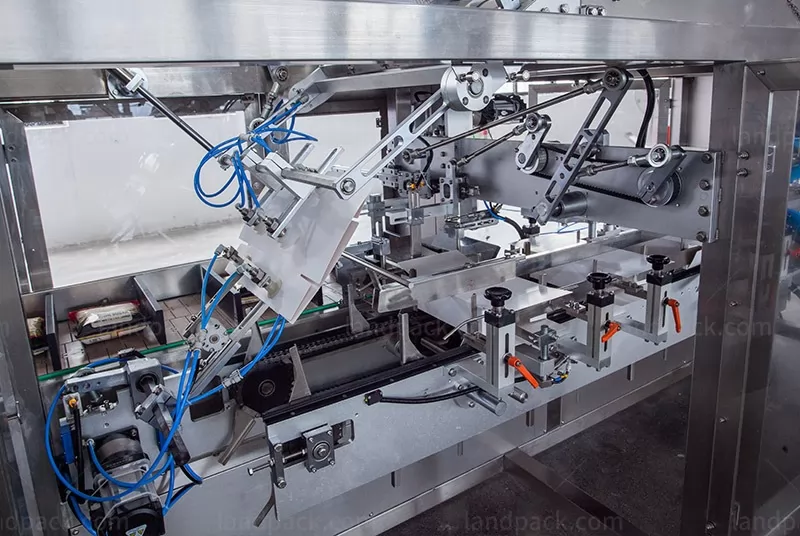

Workflow:

1. Product Conveying: Products are transported via an infeed conveyor to the cartoning area.

2. Counting & Sorting: Products are automatically counted and oriented for proper grouping.

3. Carton Box Pick-up & Forming: Pre-glued carton boxes are picked, erected, and positioned for loading.

4. Product Loading: Grouped products are horizontally pushed into the carton box.

5. Carton Box Closing: Folding and sealing carton flaps completes the packaging process.