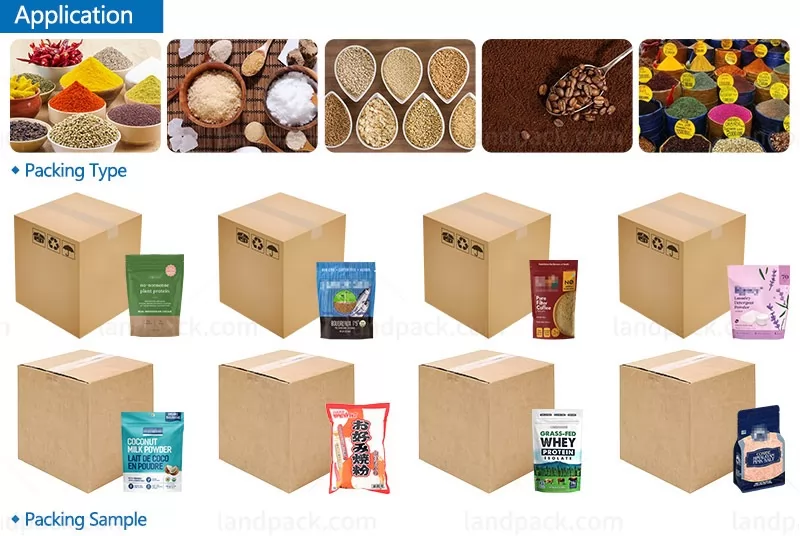

Application:

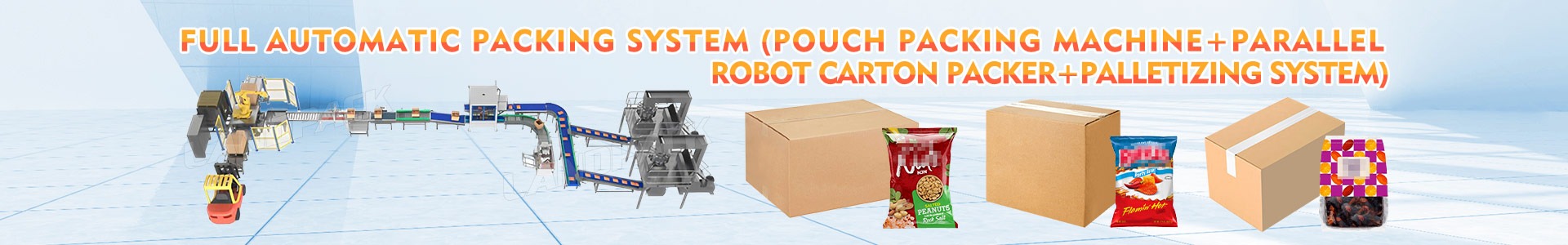

The Horizontal Premade Pouch Packaging Line With Case Packer is ideal for industries requiring both packing and cartoning solutions. It can efficiently handle food and snacks, confectionery products, pet food, frozen foods, as well as daily chemicals and non-food items. With speeds of up to 50 bags/min, it delivers a reliable and complete end-of-line packaging solution.

Wide Application Range:

The Horizontal Premade Pouch Packing Machine Line with Carton Erector and Sealer is widely used for packing different types of granule and powder material, ensuring efficient pouch packaging and secondary carton packaging. It is suitable for:

* Powder Seasonings: Curry powder, chili powder, pepper powder, five-spice powder, and other spice blends.

* Granule Seasonings: Salt granules, sugar granules, chicken essence granules, sesame seeds, and other granular condiments.

* Other Food Ingredients: Coffee powder, baking soda, starch powder, instant drink powder, and similar powdered or granulated raw materials.

This line of packaging offers secure pouch sealing as well as automatic case packaging, which makes it suitable for food, spice and ingredient industries that require primary pouch packaging as well as second-tier cartons for packaging.

Packaging Style:

The horizontal pouch packing machine combined with a carton erector and carton sealer is designed to handle a wide variety of packaging containers, offering maximum flexibility for different production needs. It is compatible with various premade pouch styles, including stand-up pouches, flat pouches, M-shape gusset pouches, and Doypacks, which are ideal for packaging powders, granules, and other food or non-food products.

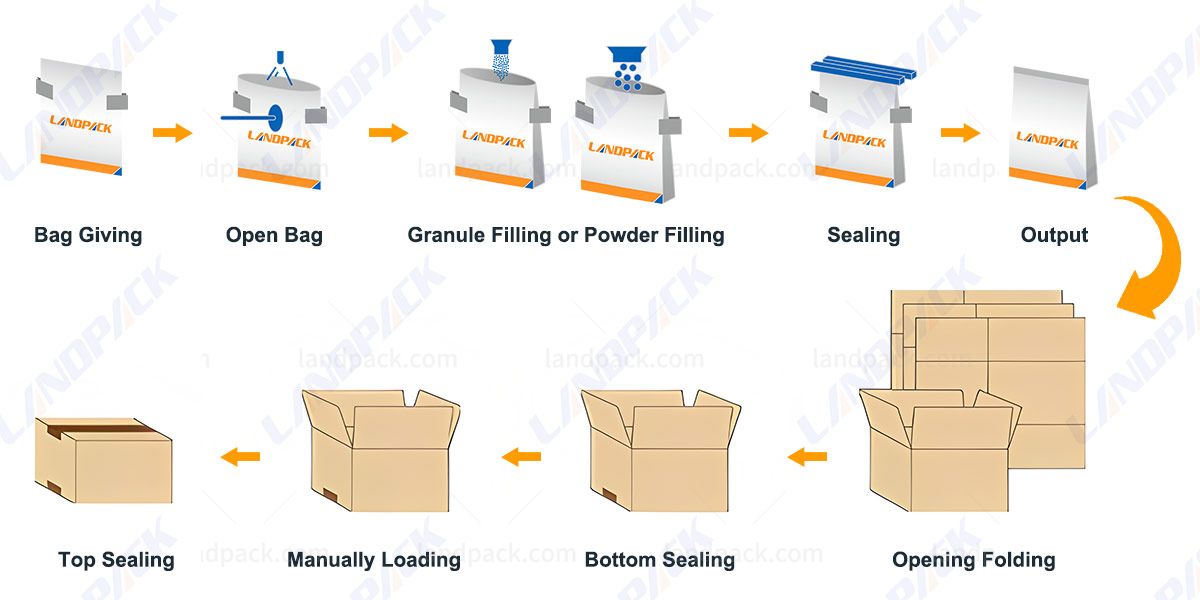

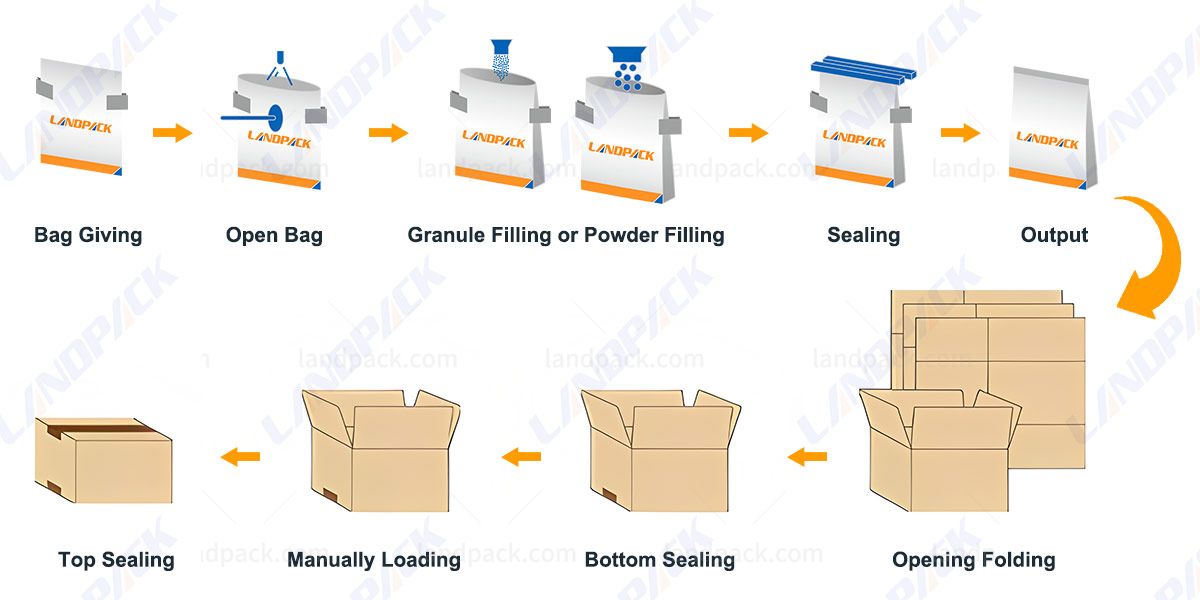

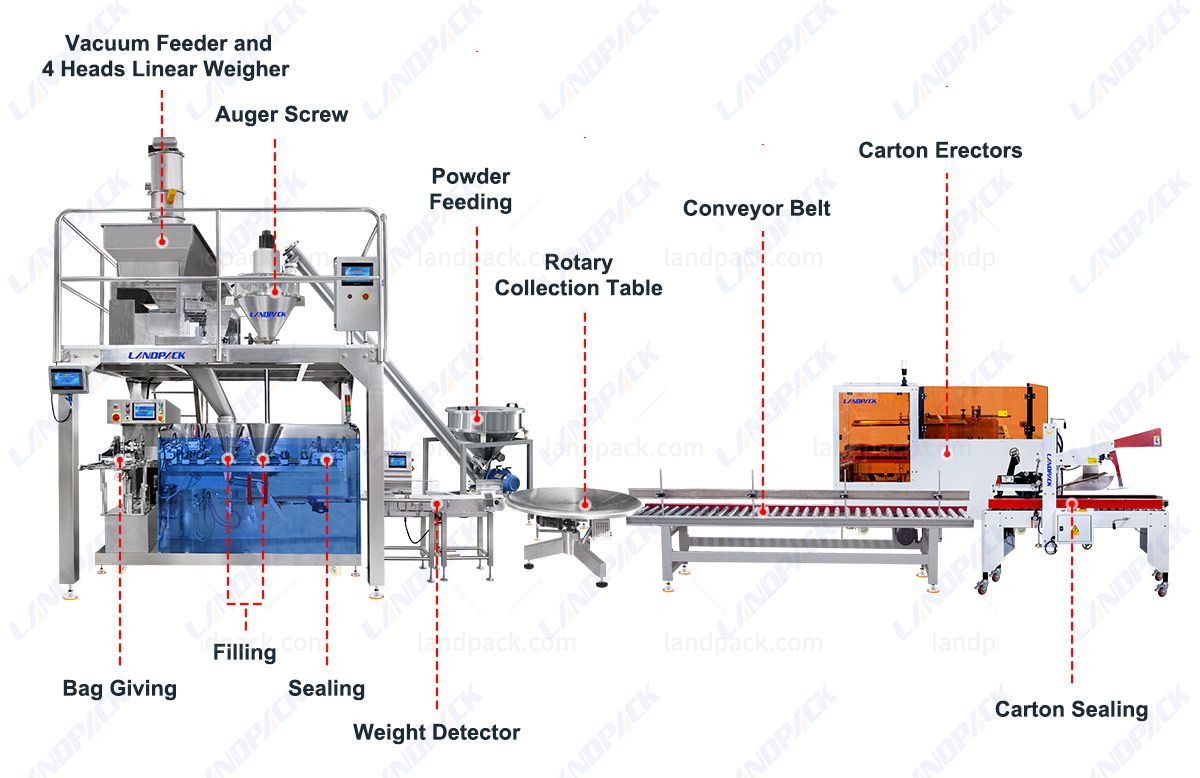

Process Workflow:

1. Automatic Vacuum Feeder Device – Materials are automatically fed into the system, ensuring a clean and efficient supply.

2. 4 Heads Linear Weigher – Accurately measures product weight with high precision.

3. Auger Filler – Consistently delivers powder into each pouch without leakage.

4. Bag Giving – Pre-made pouches are automatically placed into the machine.

5. Date Print – Production date or batch code is clearly printed on the bag.

6. Open Bag – The pouch is opened smoothly, ready for filling.

7. Filling – Product is filled into the pouch with precise dosing.

8. Dust Removal – Removes dust from the pouch opening and body for a clean finish.

9. Heat Sealing – The pouch is sealed tightly to keep the product fresh.

10. Finished Bag Output – Completed pouches are discharged neatly for collection.

11. Weight Detector – Each pouch is checked to ensure it meets weight standards.

12. Rotary Collection Table – Collects finished pouches in order for easy handling.

13. Case Opening – Cartons are automatically opened for secondary packaging.

14. Case Sealing – Filled cartons are sealed securely, ready for shipping.