Application:

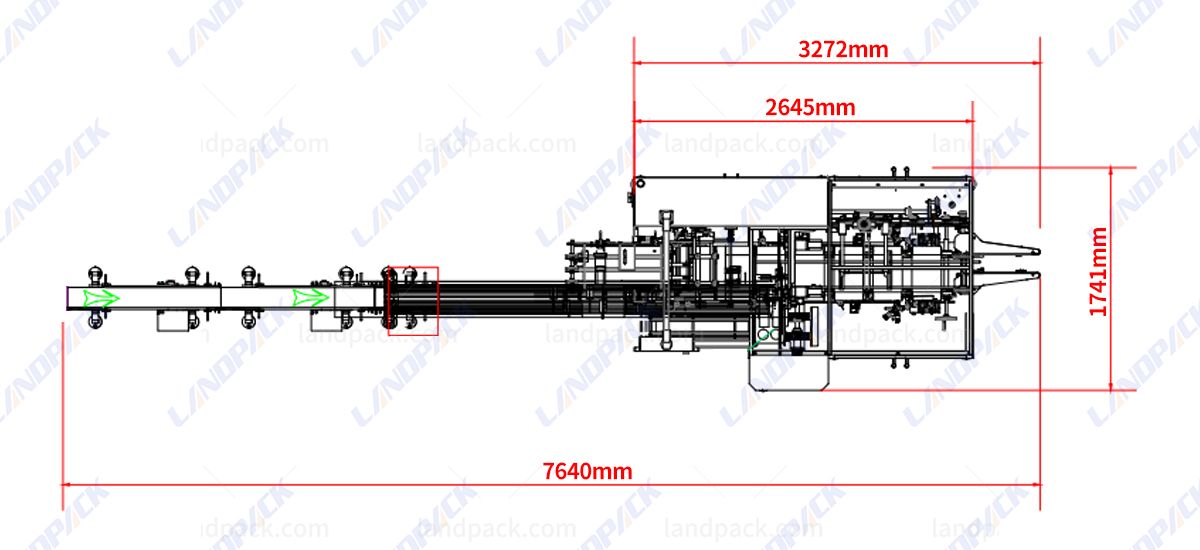

This packing system supports automatic bag counting and cartoning in continuous production lines, built for operations that value rhythm and reliability. It combines accurate counting, steady conveying, and consistent cartoning through a well-matched conveyor layout and a dependable cartoning machine. In day-to-day production, that integration cuts manual handling and keeps the line moving at a predictable pace. The system fits naturally into food, pharmaceutical, daily chemical, and consumer goods applications, where counting accuracy matters just as much as speed. With output reaching up to 60 cartons/min, it suits manufacturers who need efficient cartoning without sacrificing control. In most cases, it's a practical choice for lines that demand both precision and throughput, not one at the expense of the other.

Package Type:

This Packing System supports various flexible packaging formats for automatic counting and cartoning operations. Such as bag, pouch, sachet, stick pack, pillow pack.

Suitable Products:

This Packing System is suitable for counting and cartoning a wide range of pouch products with different forms, including solid, granular, liquid, and semi-liquid materials. With stable conveying and accurate counting performance, it ensures efficient and reliable packing for various industries.

- Snack & Food Pouches: Milk Powder, Nuts, Biscuits, Dried Fruit Snack Packs

- Granular & Solid Products: Pasta Pouches, Candy Bags, Sugar Sachets, Grain and Seed Packs

- Liquid & Semi-Liquid Pouches: Sauce Sachets, Syrup Pouches, Condiment Packs, Beverage Concentrate Bags

Workflow:

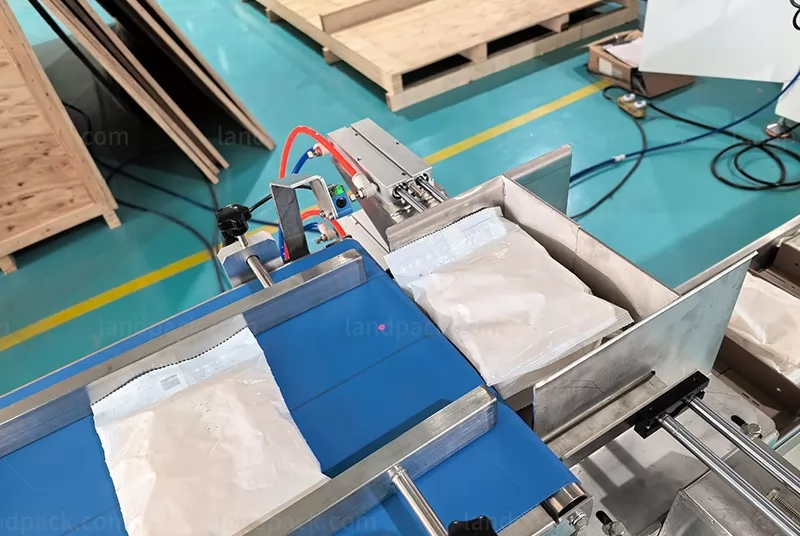

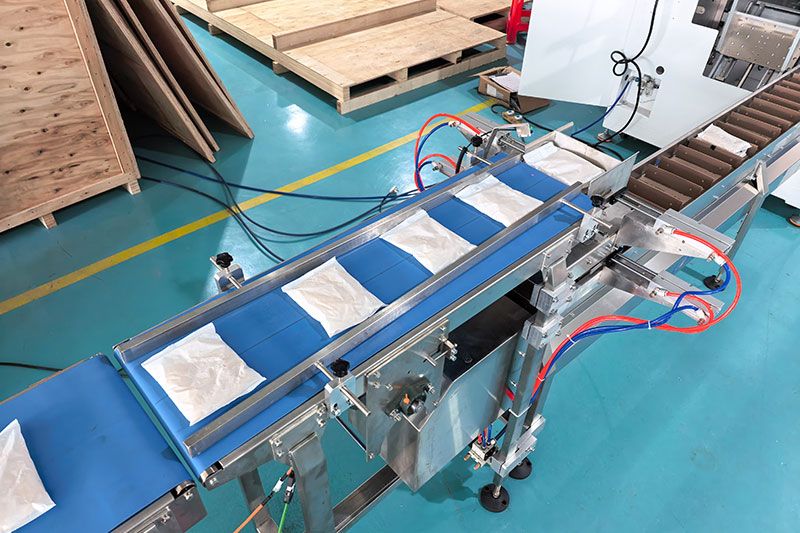

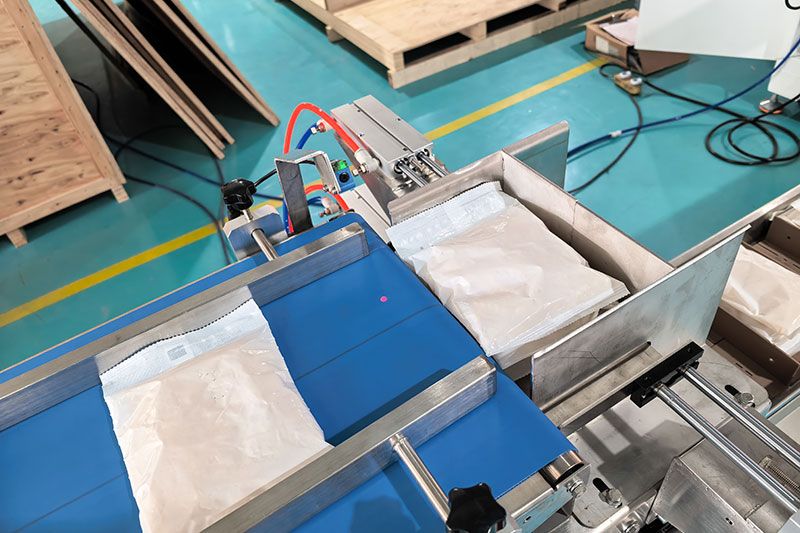

1. Conveying Bag Materials: Bag, pouch, or sachet products are smoothly conveyed through the conveyor packaging system for continuous feeding.

2. Counting: Automatic counting system ensures accurate quantity control before cartoning, reducing errors and labor costs.

3. Pack into Box: Counted products are automatically packed into boxes by the cartoning packing machine.

4. Box Lid Sealed: Box lids are sealed securely, completing the packing process and preparing products for storage or shipment.