Application:

This automatic packing system is designed for high-efficiency production lines that require fully automated handling of doypack pouches—from pouch filling & sealing, output feeding, cartoning, and robot case packing to palletizing and stretch wrapping. It is widely used in food packaging systems, snacks, powder products, dairy items, beverages, pet food, household goods, and personal care products. Integrating carton erectors, robot case packers, palletizer machines, and stretch wrapping machines, this complete solution offers improved speed, stability, and labor-saving performance for medium to large-scale factories seeking a fully automated packaging workflow.

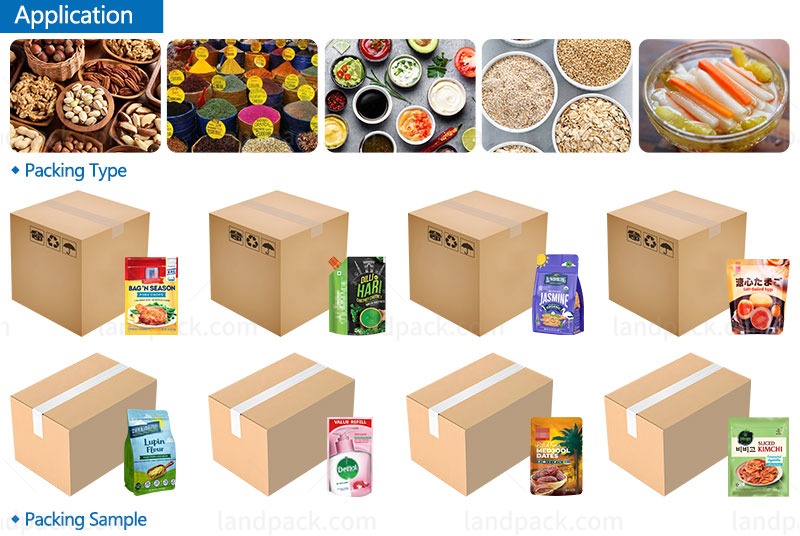

Package Type:

This automatic packing system is compatible with a wide range of premade pouches and carton boxes, making it ideal for flexible retail packaging and final secondary packing. It supports doypack stand-up pouches, zipper pouches, flat pouches, spout pouches, quad-seal bags, and other premade flexible bags. After pouch filling and sealing, the system automatically performs carton forming, product loading, and box sealing, delivering a complete pouch-to-carton packing solution.

Suitable Products:

This integrated packaging line is designed for medium- to high-output production of bagged food and non-food products. The horizontal pouch machine handles a wide variety of materials, while the robotic cartoner and palletizer support stable downstream automation. Typical applications include:

-Food Products: snacks, nuts, beans, pasta, grains, dried fruits, powders, sauces in spout pouches, pet food

-Daily & Chemical Products: detergent pods, dishwasher powder, cleaning granules, cosmetic refills

-Industrial & Miscellaneous Goods: small parts, hardware kits, agricultural seeds, chemical granules

Its flexible pouch compatibility and carton loading capability make it suitable for factories producing multiple SKU formats in large volumes.

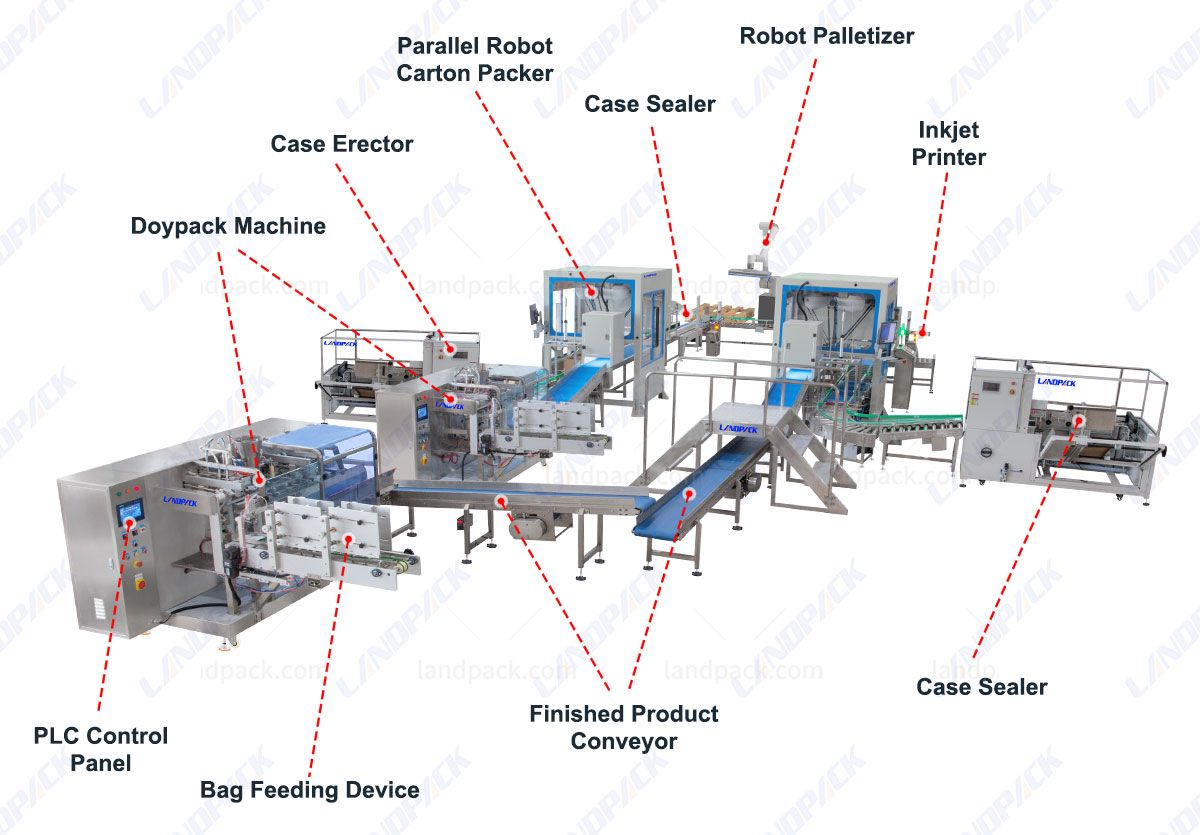

Workflow:

1. Doypack Pouch Packaging – First filling and sealing your products into premade pouches.

2. Carton Opening –Automatically forms and opens boxes for packing.

3. Carton Packing – Neatly load finished pouches into the opened cartons.

4. Weight Detection – Weighing the carton to ensure the weight is accurate.

5. Carton Sealing – Automatically closes and seals the carton.

6. Coding – Printing date, batch, or barcode information on the sealed cartons.

7. Palletizing – Stacked finished cartons onto pallets by a robotic palletizer for the next step or shipping.