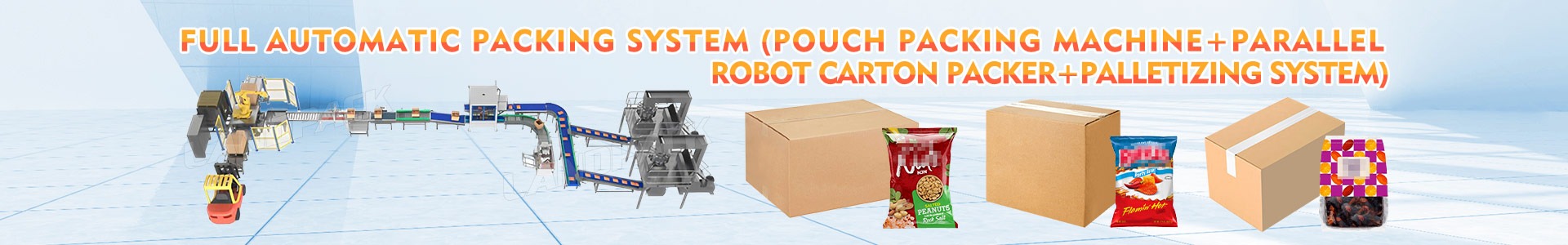

Application:

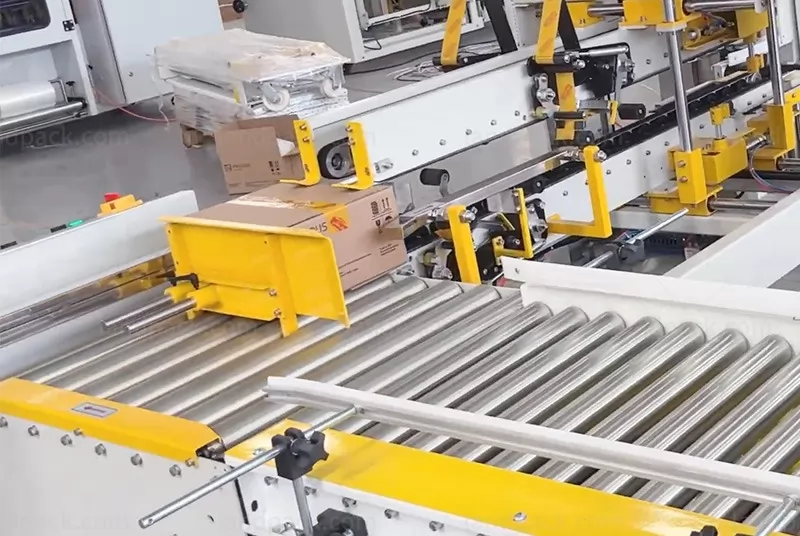

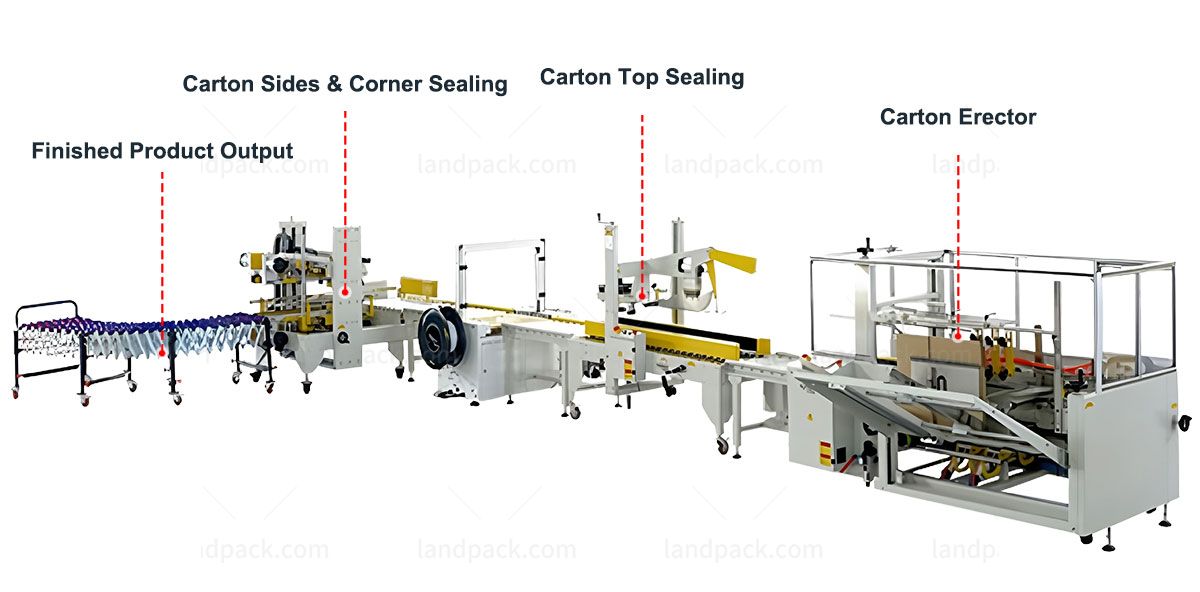

Our automatic case packing system combines Carton Erector, Carton Sealer, Labeling Machine, and Strapping Machine in one integrated line. Widely used in food, beverage, pharmaceutical, household, and logistics industries, it ensures reliable carton packaging, secure sealing, clear labeling, and efficient strapping for smooth production.

Wide Application Range:

The Carton Packing & Strapping Line is designed to handle a diverse range of products across different industries, ensuring safe, efficient, and reliable packaging.

* Food: Nuts (almonds, walnuts, cashews), cakes, instant noodles, bottled or canned drinks, etc.

* Daily Products: Detergents (powder, liquid, pods), shampoos, hair care products, toothpaste, disinfectant sprays and cleaners, etc.

* Medical Supplies: Health supplements, alcohol bottles, disposable gloves, medicine boxes and blister packs, etc.

Packaging Style:

Efficiently designed for all industries, this line automates carton packing and strapping in one seamless process. It saves labor, enhances efficiency, and ensures cartons are secure, stable, and transport-ready.

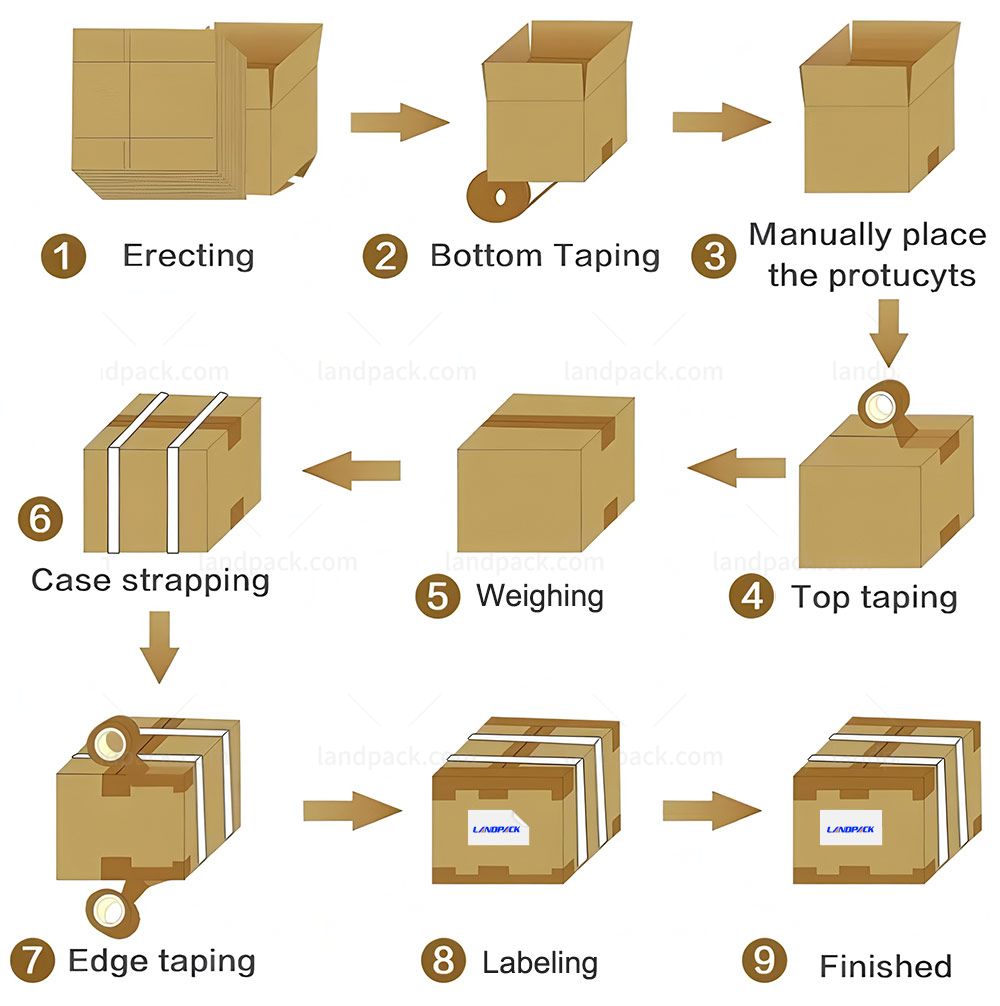

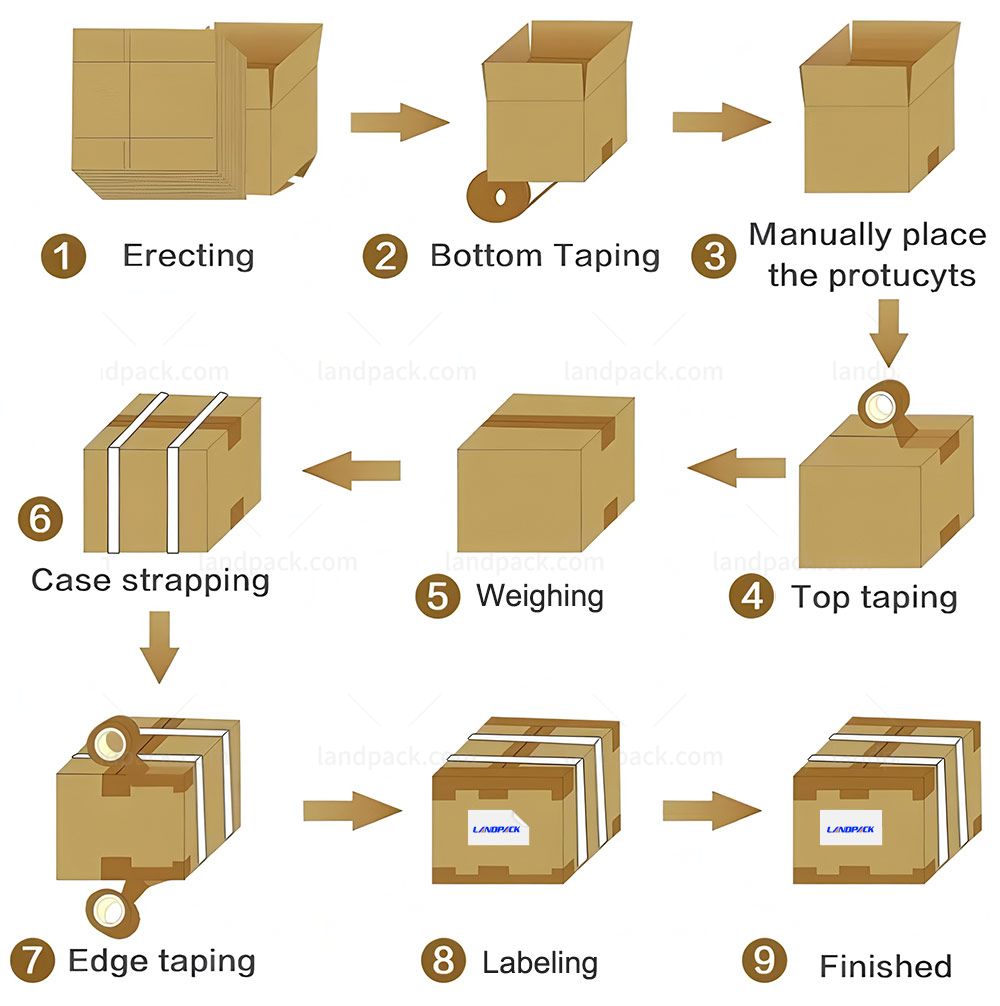

Process Workflow:

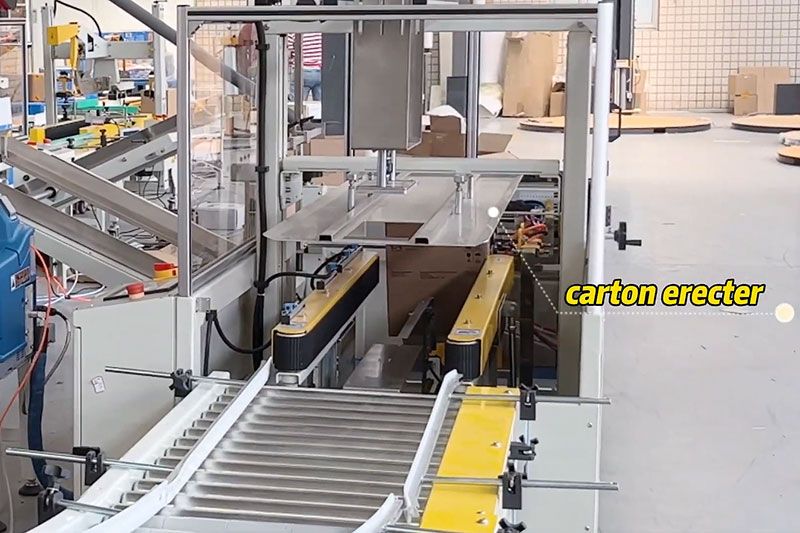

1. Erecting: Flat cardboard boxes are built automatically into boxes, ready to be packed.

2. Bottom Taping: It is sealed at the bottom by tape to ensure it is stable and secure.

3. Product Loading: Items are put manually in the boxes in an orderly manner to ensure safe transportation.

4. Top Taping: It is taped to the top with tape, which protects the contents within.

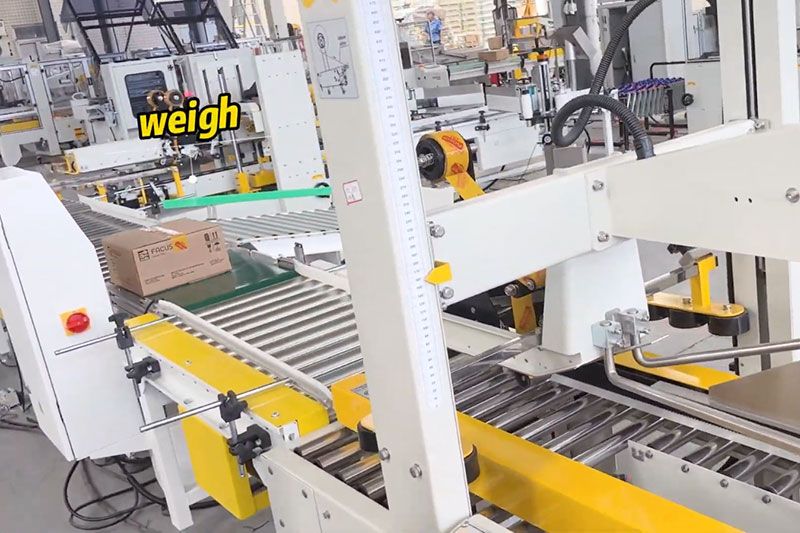

5. Weighing: Each box is weighed to ensure that the packaging is correct and meets the shipping specifications.

6. Case Strapping: Strong straps are positioned around the carton to secure it and stop it from opening during handling.

7. Edge & Corner Taping: Edge & corner taping is also applied to provide a more secure seal and protection.

8. Labeling: Labels are used to provide information about the product, tracking or for shipping identification.

9. Finished: The box is now sealed, packed and is ready to be delivered.