Application:

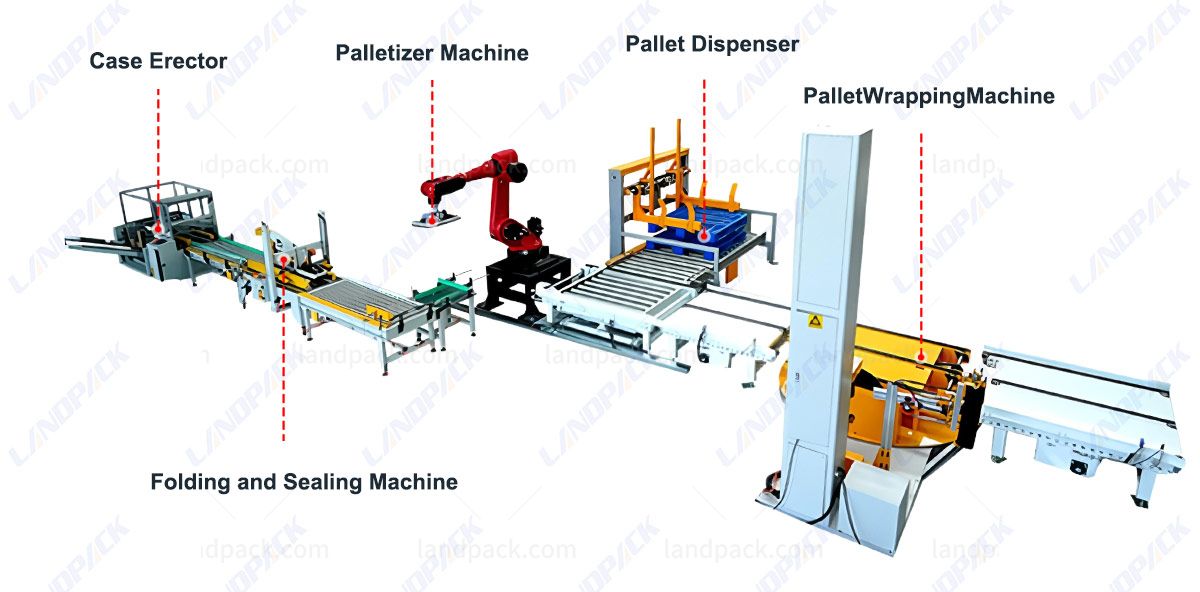

The automatic carton palletizing system is composed of six main sections: the carton erecting and sealing unit, pallet dispenser, robotic palletizing unit, automatic wrapping machine, and integrated conveying system. These modules can be flexibly combined according to production needs and can also be seamlessly connected with a delta robot for a fully automated end-of-line solution.

Suitable Industry:

*Food Industry: Biscuits, cookies, chocolate, potato chips, puffed foods, candy, nuts, dried fruit, bread, cakes, instant noodles, frozen foods

*Beverages: Bottled water, juice, functional drinks, coffee drinks

*Daily Chemical Products: Laundry detergent, dishwashing liquid, soap, shampoo, shower gel

*Pharmaceuticals and Health Products: Tablets, capsules, protein powder, disposable masks, gloves

*Agrichemicals: seeds, feed, fertilizers, coatings/paints, lubricants

Packaging Style:

This Robot Case Packer With Palletizing System is suitable for loading boxed products from different industries into cases.

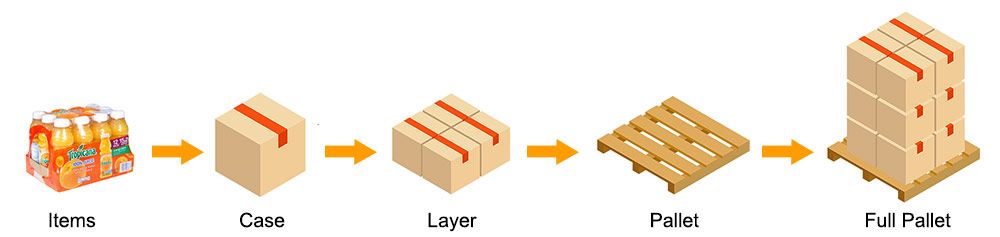

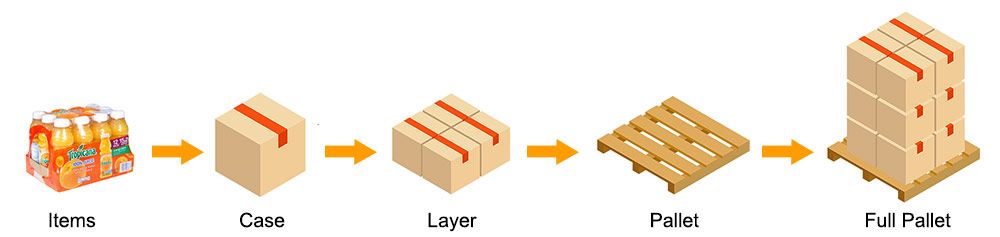

Process Workflow:

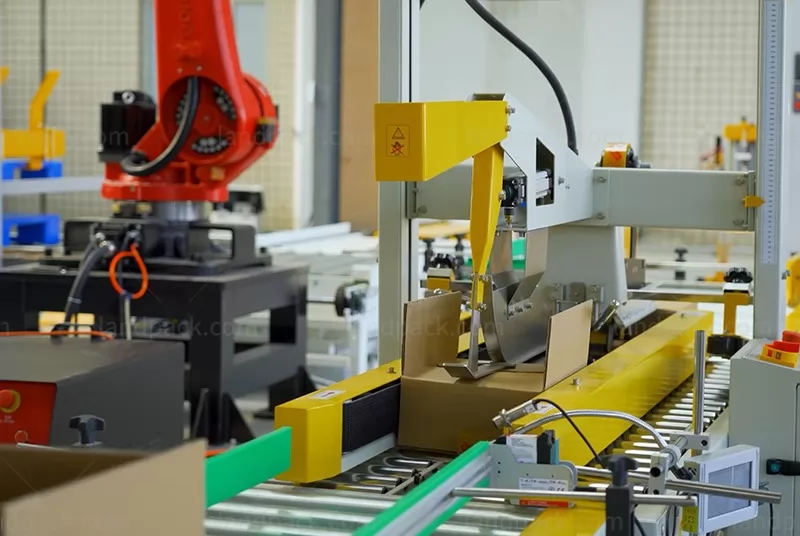

1. Carton Formation - Using advanced forming mechanisms, flat blanks are separated, folded into cartons, and sealed at the bottom—preparing them promptly for filling.

2. Loading and Sealing - Cartons are filled with products—either manually or robotically—and then sealed, ensuring secure containment before moving further.

3. Robotic Palletizing - Cartons continue along the conveyor to the robotic palletizing station.

4. Stretch Wrapping - Completed pallets are automatically transferred to the wrapping station, where stretch film is applied.