Application:

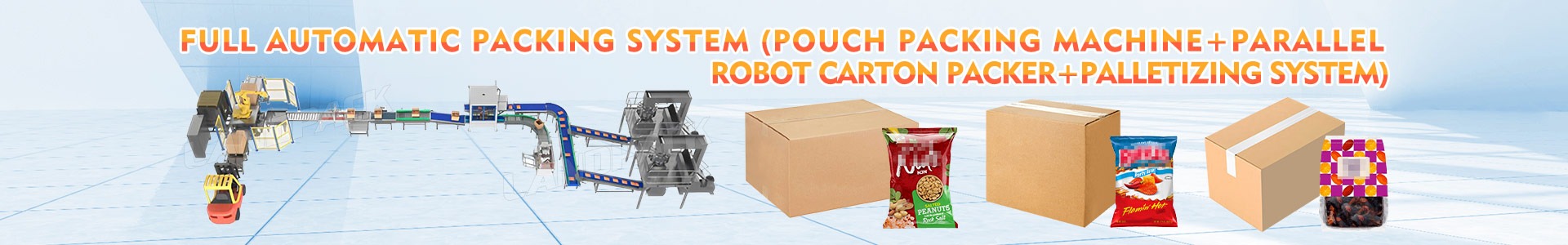

Our automated food packaging systems with robotic packers and palletizers are ideal for food factories, especially pickled and canned food production, ensuring consistent cartoning and stable palletizing at high speed.

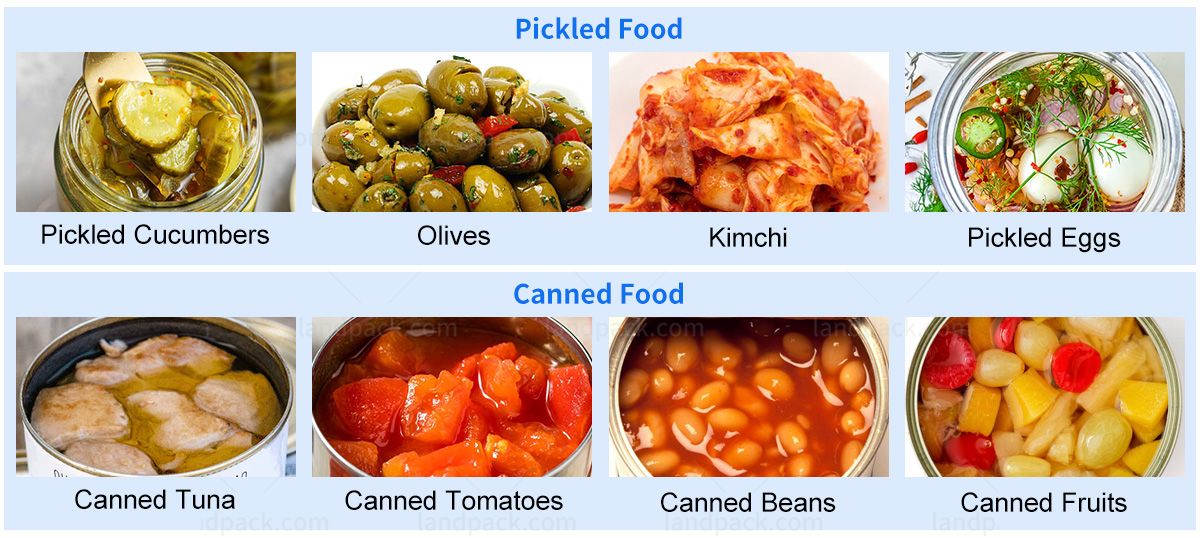

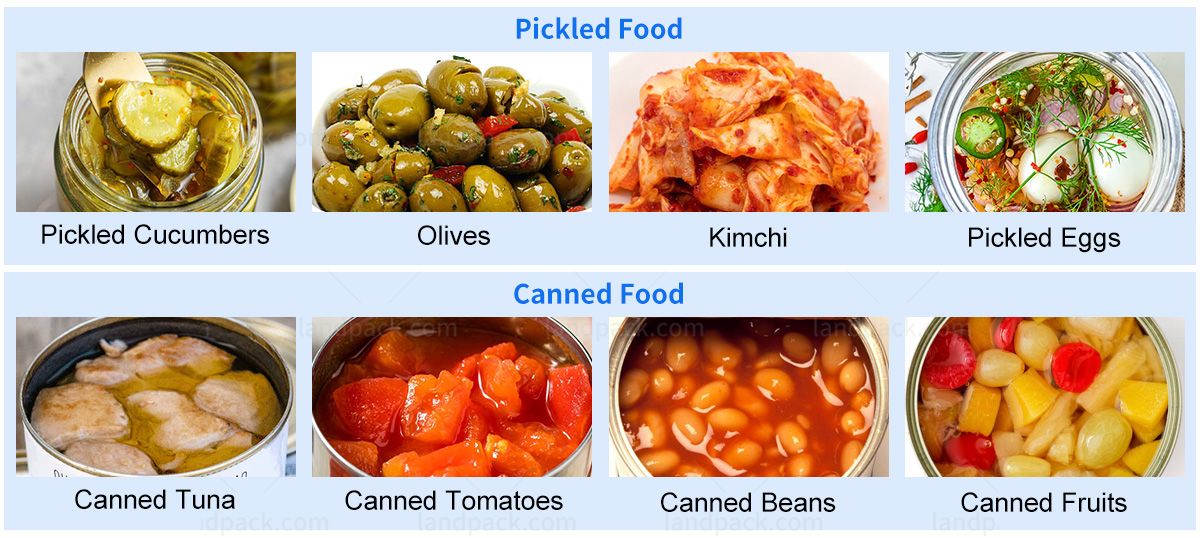

Wide Application Range:

This filling, packing and palletizing line has been specifically designed for canned and pickled food items to ensure an efficient packing process, safe transportation and a long shelf life.

* Pickled Foods: It is ideal for packaging products made of pickled ingredients, such as olives, cucumbers, pickled eggs, kimchi and pickled onions.

* Canned Foods: A wide variety of canned food items are used in production, such as canned tuna and canned tomatoes canned soup, canned beans and canned fruit.

With its high level of automation and reliability, this line is perfect for companies looking to increase efficiency and improve the quality of their products for the processing of food and in the packaging industries.

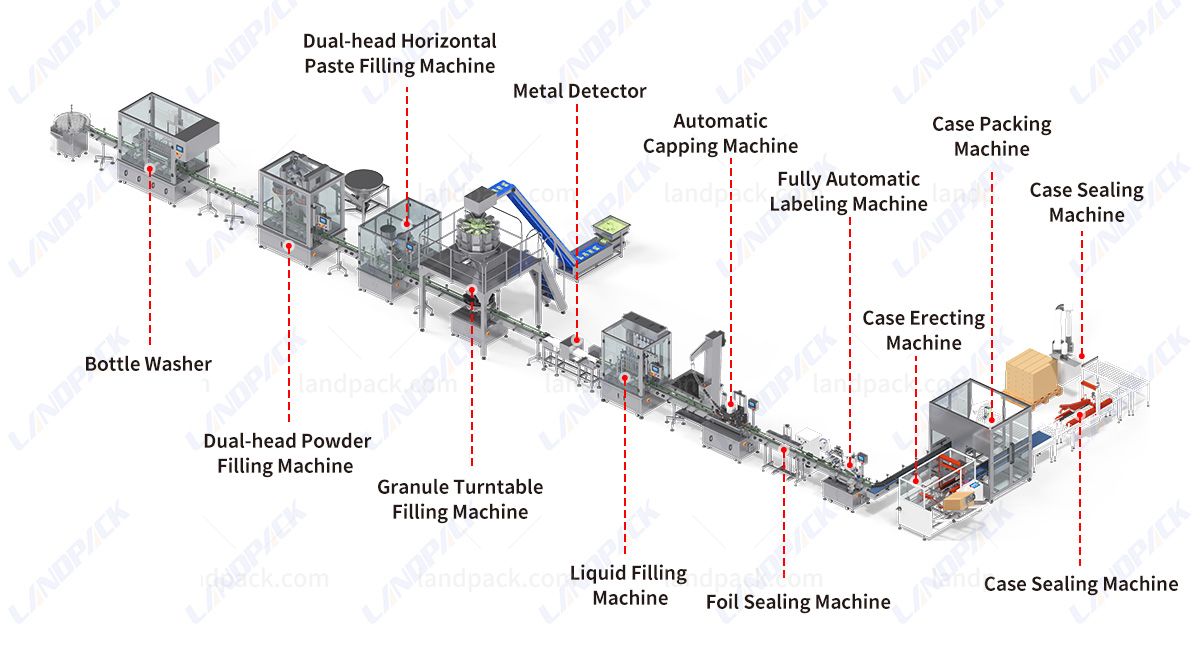

Packaging Style:

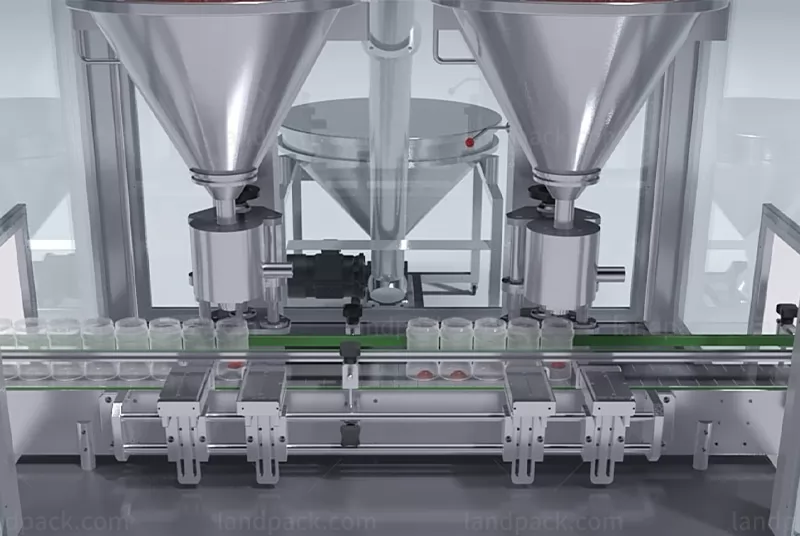

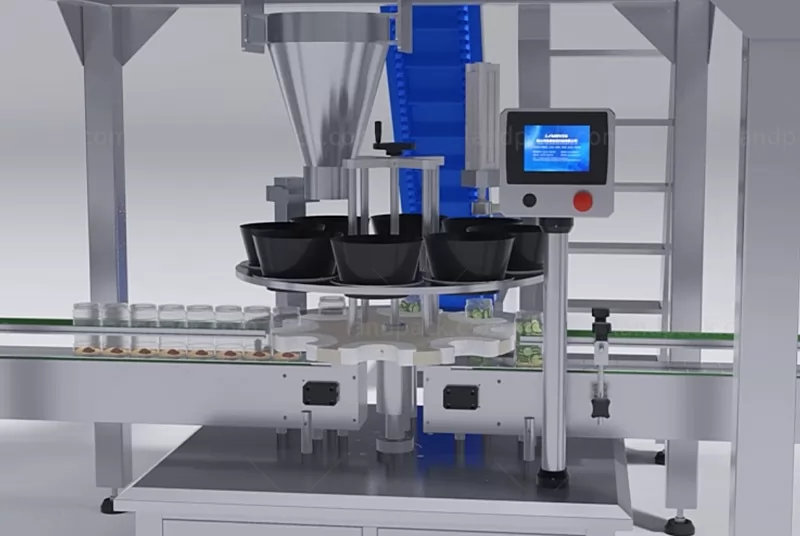

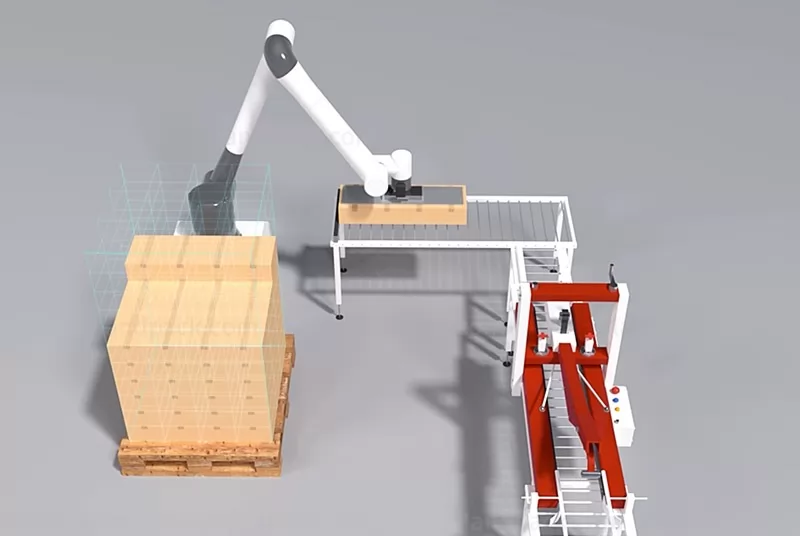

This filling, packaging and palletizing line is made for different rigid packaging containers like tin cans plastic bottles, glass jars and other can-type sealed containers. After the precise filling, items are arranged neatly into boxes using an automatic packing system, sealed and labeled, then placed on pallets using an automated palletizing system. This guarantees a uniform and efficient packaging and makes the items simple to handle, store and move.

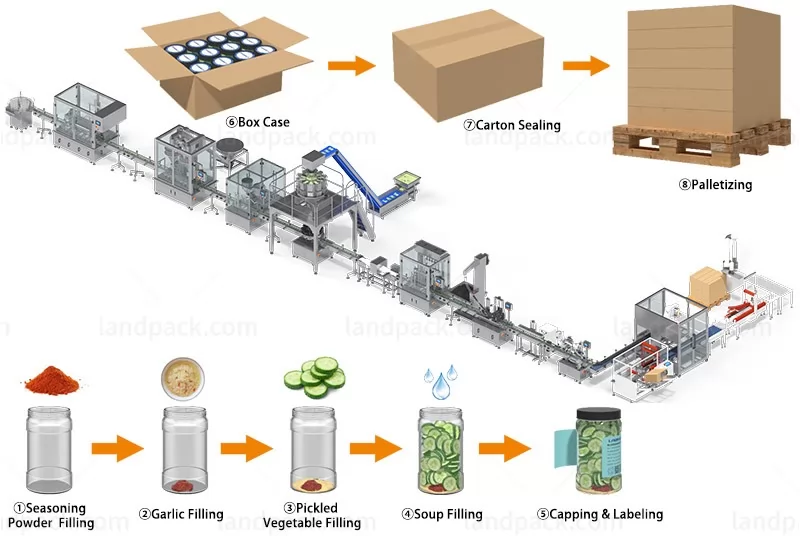

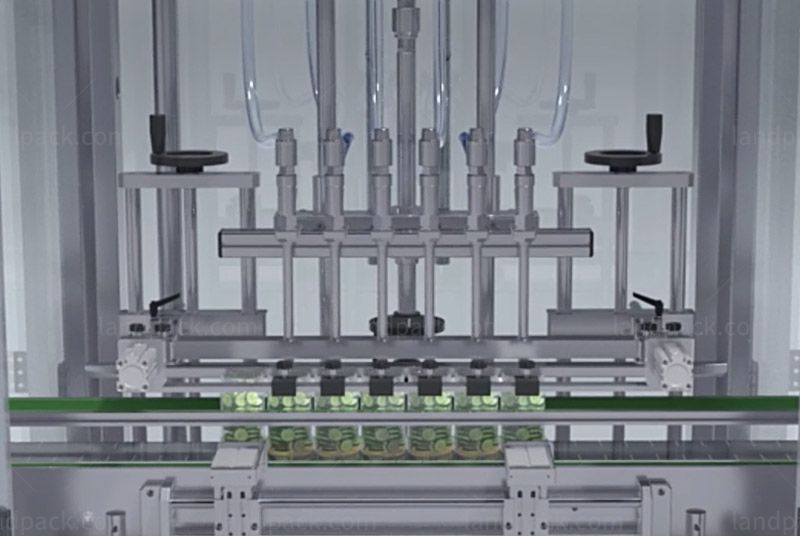

Process Workflow:

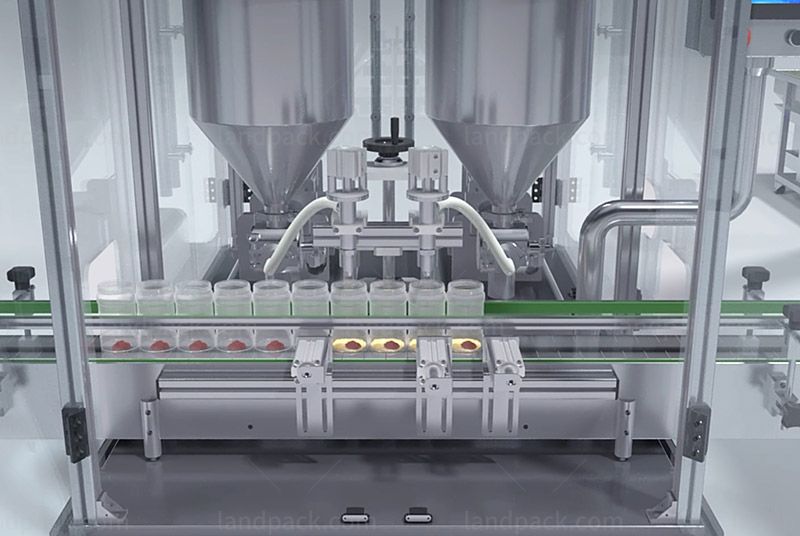

1. Seasoning Powder Filling: Add an appropriate amount of seasoning powder into jars, bottles or cans empty as a flavoring base.

2. Garlic Filling: Spread a small amount of chopped garlic in order to increase the aroma and flavor.

3. Pickled Vegetable Filling: Fill the jar with diced or cut picked vegetables.

4. Soup (Brine) Filling: Filling the soup into the bottle to maintain the vegetables fresh and tasty.

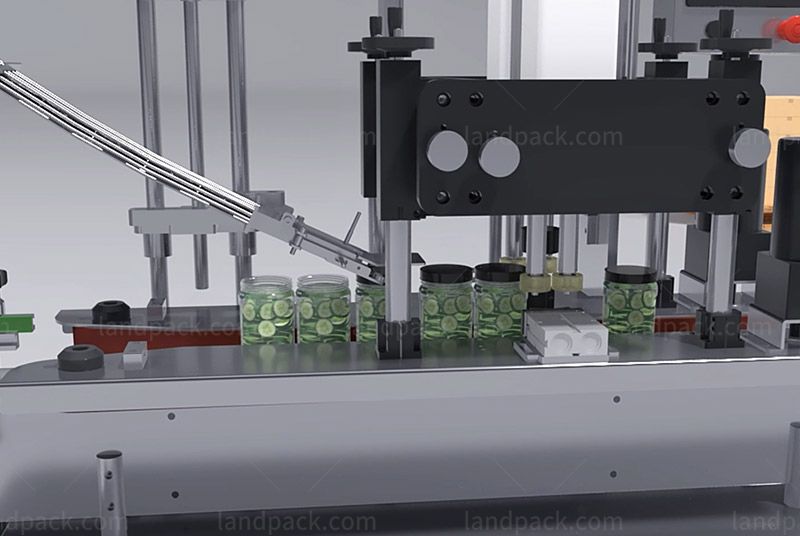

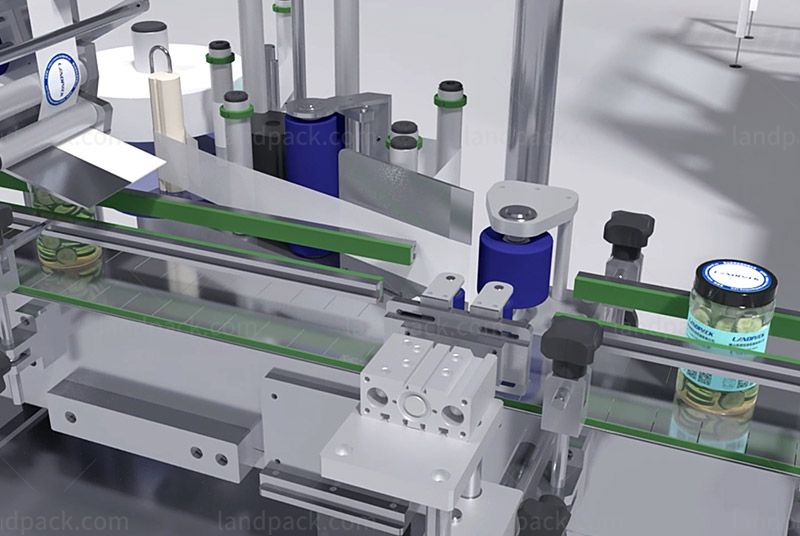

5. Canning/Bottling & Labeling: Securely capping the cans, bottles and jars. Label the bottles/cans/jars/cans to ensure the identification and for branding.

6. Box Case Packing: Case packing robot puts jars, cans and bottles neatly in boxes/cartons to make it easy to transport.

7. Carton Sealing: Seal the cartons to ensure the contents remain safe during shipping.

8. Palletizing: Palletizer machine puts the cartons that have been sealed on pallets to facilitate massive handling and delivery