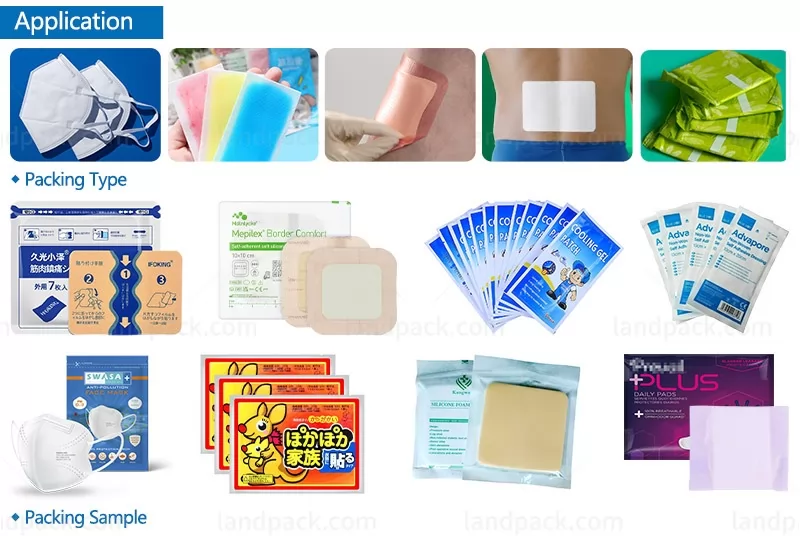

Application:

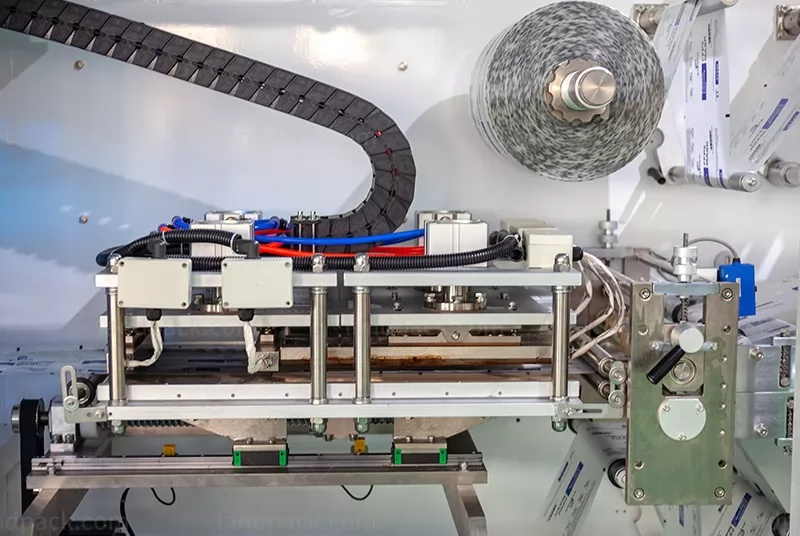

High-speed automatic double channel four side sealing packing machine, achieving outputs of 80-100 bags/min. Designed for food, daily necessities, & medical supplies. Our dual-line synchronous operation doubles productivity while ensuring precise and hermetic seals on all four sides for superior package quality. Perfect for high-volume production lines.

Wide Application Range:

Our dual-channel 4 side sealing packing machine is an automated packaging solution designed for modern high-speed production lines. Its innovative dual-channel system processes two product lines simultaneously, significantly boosting efficiency and output—making it the ideal choice for businesses seeking unmatched productivity without compromising quality.

* Food: Perfect for sealing gummy candy bars, beef jerky, seaweed, pet treats, etc.

* Daily Product: Ideal for packaging warm packs, facial masks, sanitary napkins, aromatherapy cards, etc.

* Medical Supplies: Suitable for packing masks, fever patches, silicone dressings, medical tapes, and gauze, etc.

Packaging Style:

Our dual-channel 4-side sealing packaging machine is an advanced system specifically engineered for 4-side sealing packaging processes. It supports various bag types and materials, ensuring perfectly sealed, neat, and high-quality packaging for every product. Whether for food, daily products, or medical supplies, this machine delivers efficient and reliable 4-side sealing performance.

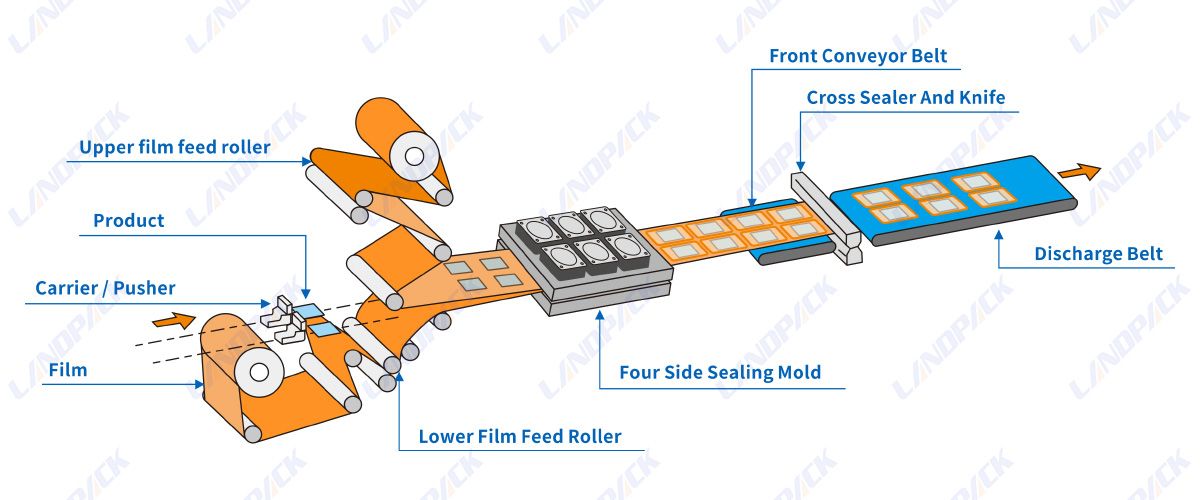

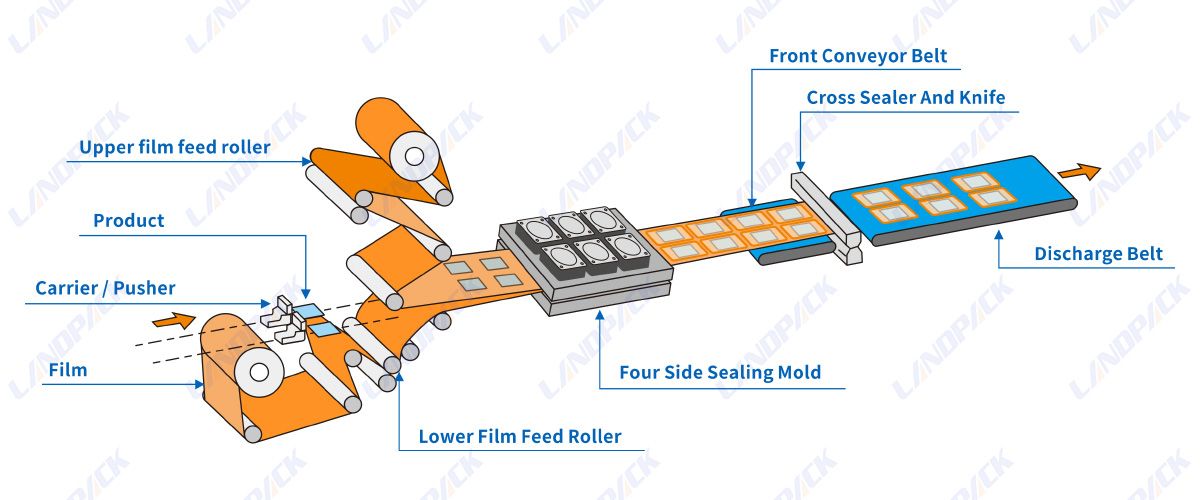

Workflow:

This four side sealing packing machine is for food, daily products, Medical Supplies in 4 side sealing bag. Here's how it works step-by-step:

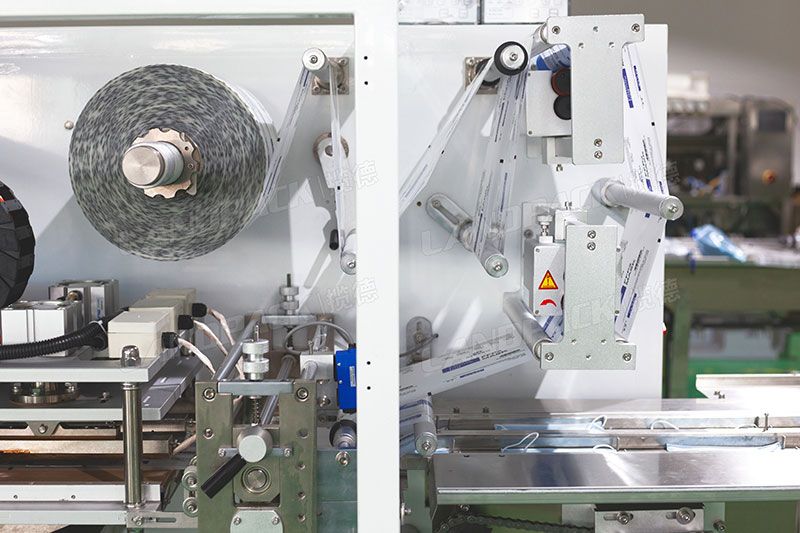

1. Film Feeding: Upper and lower film rolls are automatically fed into the machine to prepare for wrapping.

2. Product Loading: Products are placed on the carrier/pusher and moved forward into the packaging section.

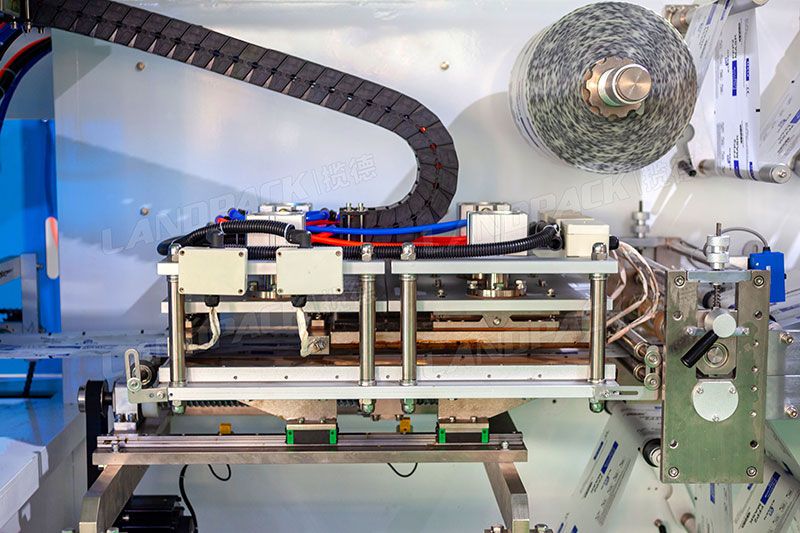

3. Four-Side Sealing: The films are wrapped around the products and sealed on all four edges inside the sealing mold to form a tight package.

4. Cross Sealing & Cutting: The continuous sealed film strip is cut into individual packs by the cross sealer and knife.

5. Product Discharge: Finished four-side sealed sachets are delivered onto the discharge belt for collection or downstream packaging.