Application:

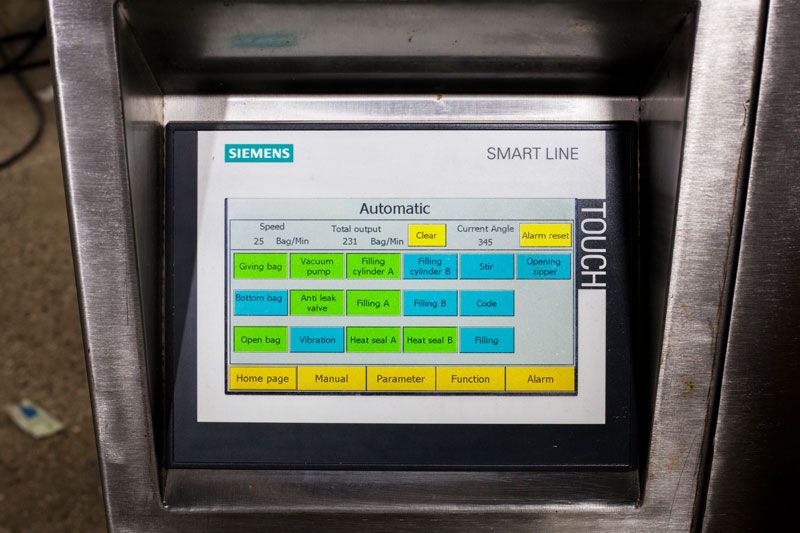

Capable of packaging pastes, detergent liquids, sauce, and syrup, it operates at up to 60 bags/min with minimal material waste. Its user-friendly interface permits rapid adjustments for various sizes and types of pouches with the assurance of flexibility, high sealing strength and reliable production capacity.

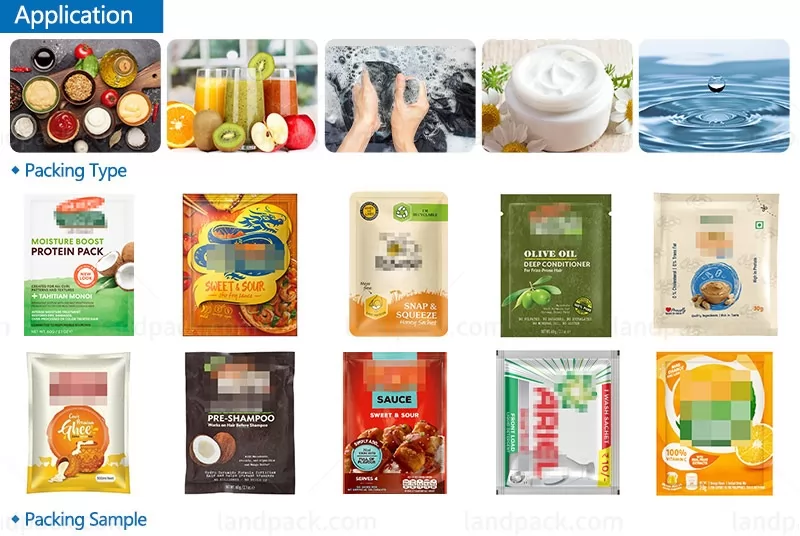

Wide Application Range:

The 4 side sealing bag packing machine is designed for a wide range of liquid and paste products. Below is common application areas and product types:

* Paste Products:

Peanut butter, chocolate sauce, mayonnaise, honey, ketchup.

* Juice & Sauce:

Mixed fruit juice, milk, syrup, olive oil, soy sauce.

* Daily & Industrial Liquids:

Liquid soap, disinfectant, detergent, engine oil, pesticide.

Packaging Style:

This machine supports lots of packing types, including premade pouches, 3 side sealing bags, and 4 side sealing bags, sachet.This pouch type supports small sachets or larger pouches, providing both convenience and premium shelf display.

Process Workflow:

1. Bag Feeding: The machine picks up 4 side sealing bags in the bag feeder and puts them neatly onto the running machine.

2. Bag Opening: Utilizing suction cups and mechanical armor, this bag can be unlocked from the top to ensure it's prepared for filling.

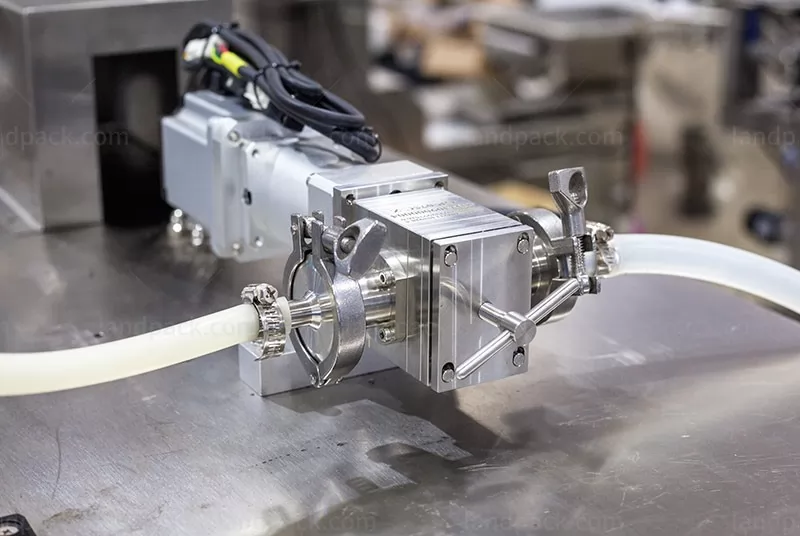

3. Filling: The product, whether it is liquid powder, paste, or granules is precisely put into the bag via Dosing System (pump or auger or weighing device).

4. Sealing: Bags are sealed on all four sides by heat and pressure, resulting in a an airtight, strong seal.

5. Finished Bag Output: The bags that have been made are then redirected onto the conveyor