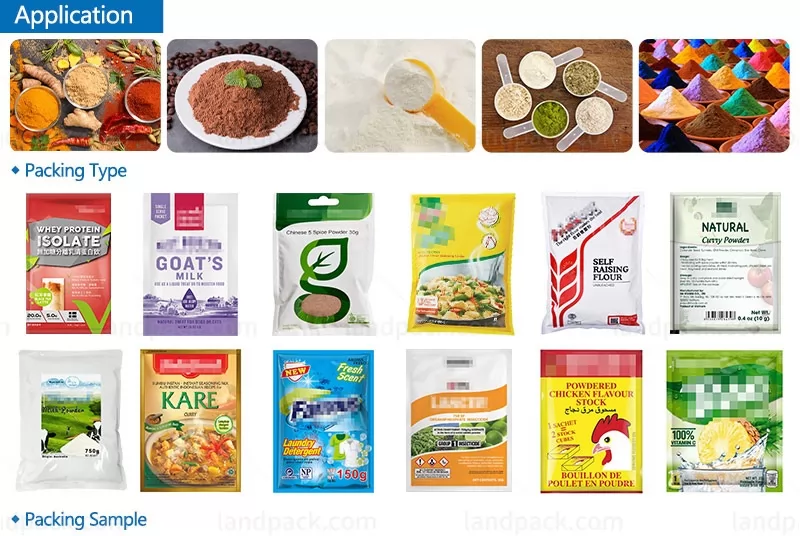

Application:

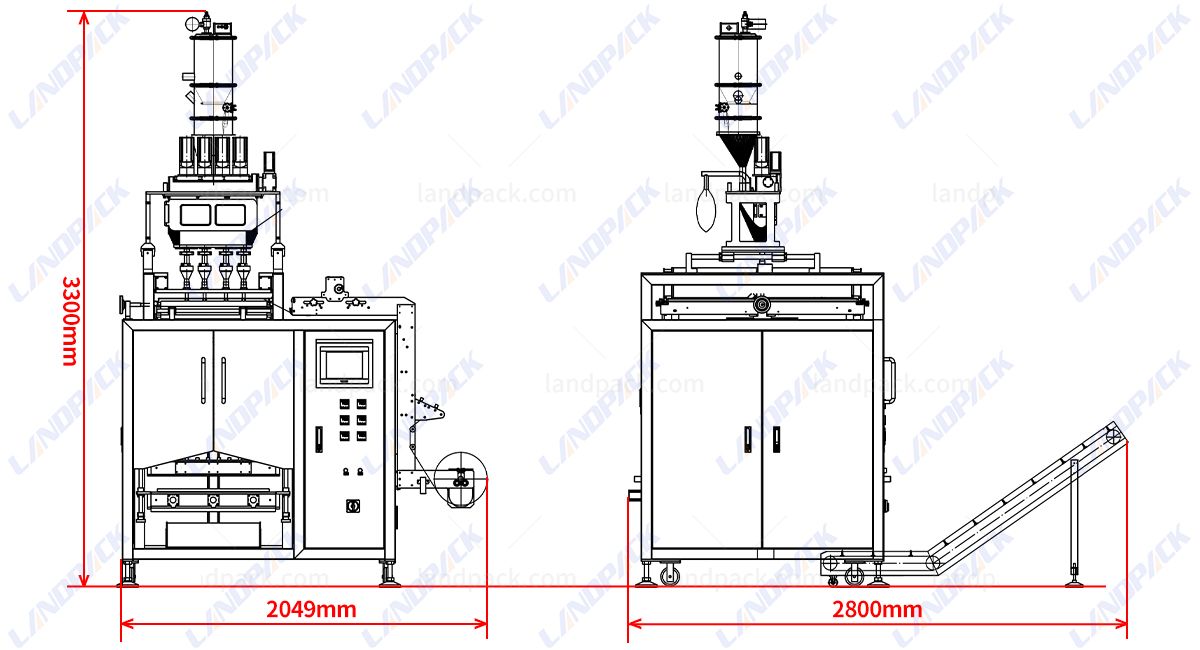

High-speed multi-lane powder sachet 4 side seal packaging machine designed for precise dosing and efficient packaging. Operating at 20-40 bags/min/lane, it ensures consistent quality for small powder sachets in various industries.

Wide Range of Powder Applications

Our 4-side multi-lane seal powder packaging machine is designed to handle a range of fine powders in various industries, providing precise, efficient and safe packaging.

* Food & Beverage Powders

Milk powder, whey protein coffee powder and seasoning powders (spices chili powder, curry powder, etc.)

* Household / Cleaning / Chemical Powders

Powders for soap, talcum powder, fragrant powders (laundry fragrance powder and dust fresheners), additives for agriculture (fertilizer powder and feed additives)

* Nutraceutical / Pharmaceutical / Cosmetic Powders

Powders of vitamins, botanicals (green matcha powder, tea, and herbal powders), pharmaceutical powders (medicine premix oral supplements), and cosmetic powders (facial powder, mask powder)

Packaging Type:

This multi lane sachet packaging machine is compatible with 3/4 side seal bag with or without europe hole, providing flexible packaging options for various powder products.

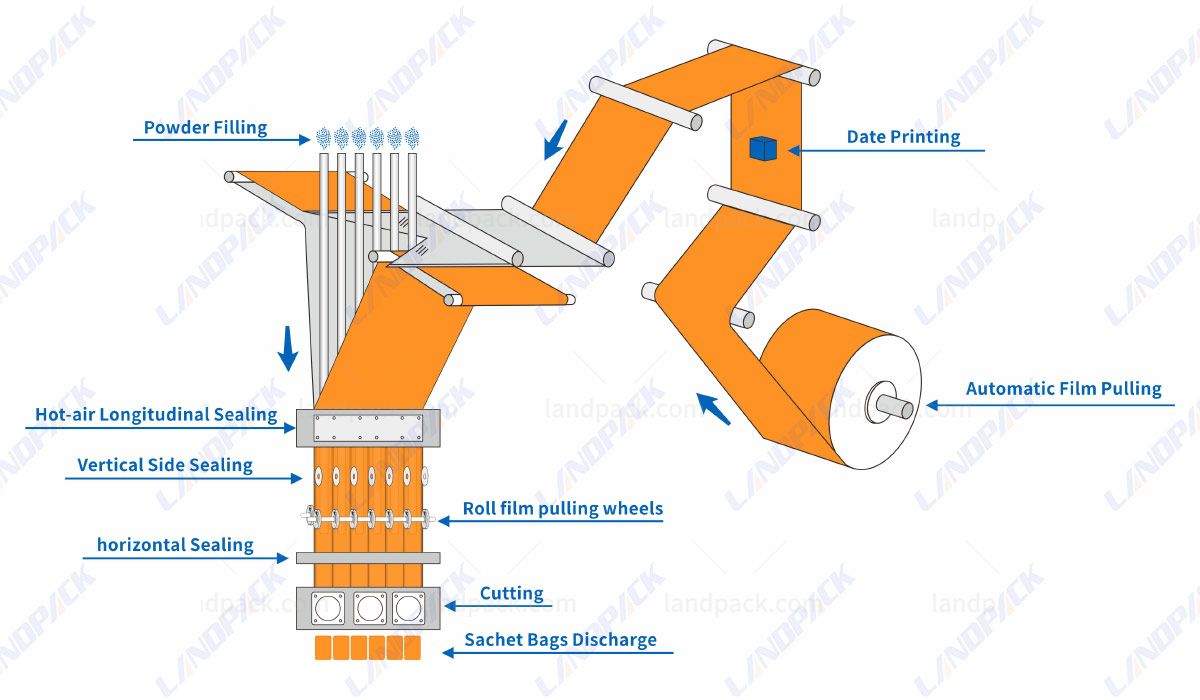

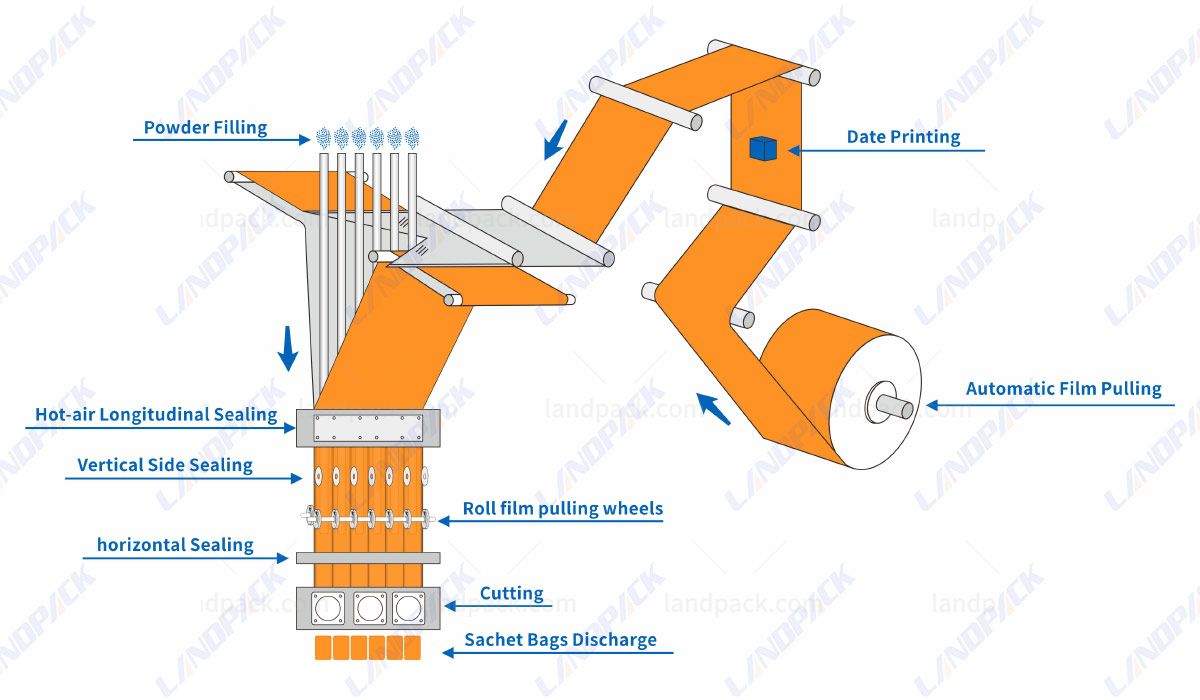

Workflow:

This is multi lane 4 side seal sachet packaging machine for powder products. Here's how it works step-by-step:

* Automatic Film Pulling: The packaging film is automatically pulled from the roll to start the process.

* Date Printing: A printer marks the production date or batch code onto the moving film.

* Film Guiding & Pulling: The film passes through guiding rollers and pulling wheels to ensure it moves smoothly and accurately into the forming section.

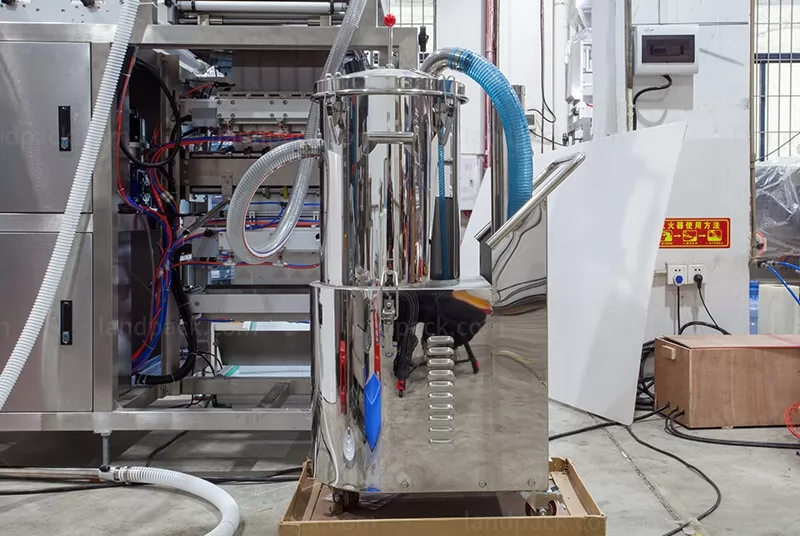

* Powder Filling: Multiple filling nozzles accurately dispense the powder into each formed film channel.

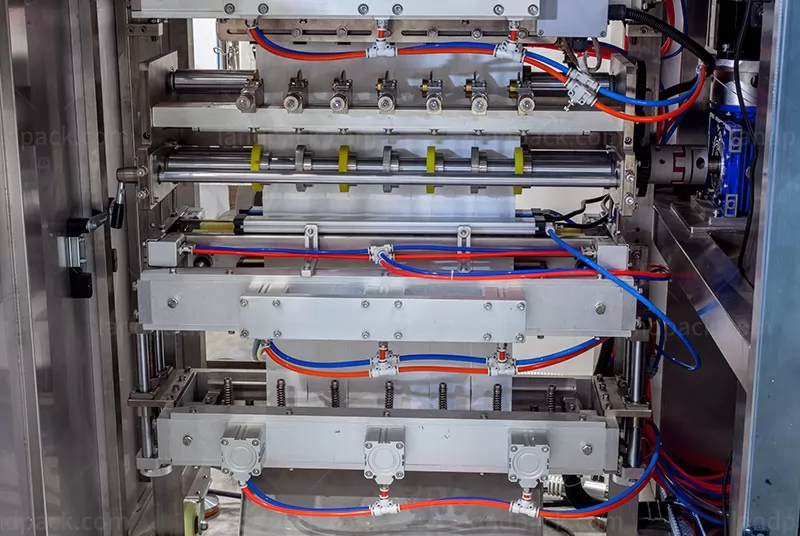

* Hot-air Longitudinal Sealing: Hot air is applied to seal the film along its length, forming continuous vertical tubes.

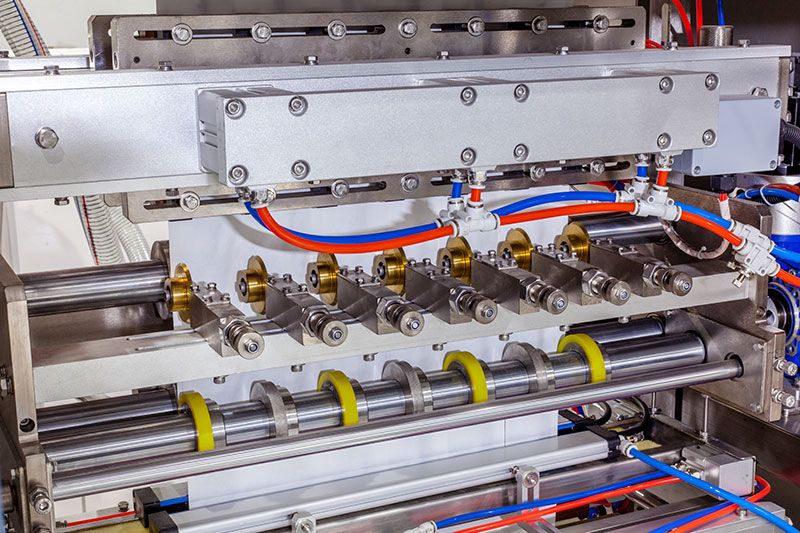

* Vertical Side Sealing: Each lane is sealed along its vertical edges to create separated sachet strips.

* Horizontal Sealing: Heat sealing bars press across the sachets to form the top and bottom seals of each bag.

* Cutting: The sealed sachets are cut apart into individual small packs.

* Sachet Bags Discharge: The finished sachets are discharged neatly for collection and further packing.