Application:

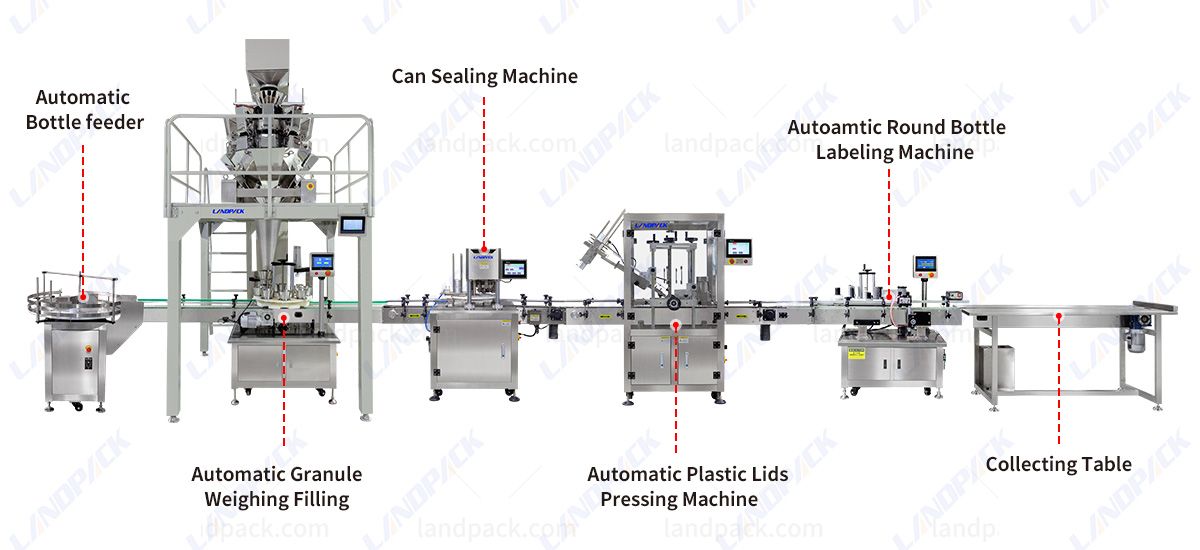

The Gummy Cans Filling Seaming Machine Line is specially designed for efficient and hygienic packaging of various gummy candies into metal or plastic cans. With a production speed of 30 cans/min, this gummy filling machine ensures high accuracy, minimal waste, and a smooth continuous workflow. The system integrates filling, vibration leveling, foil sealing, capping, and seaming into one fully automatic line, ensuring stable performance and excellent sealing integrity.

Package Type:

The Gummy Cans Filling Seaming Machine Line is designed to handle a wide range of bottles and cans made from different materials, offering full flexibility for various production needs. It is compatible with plastic bottles, tin cans, aluminum cans, glass jars, and PET containers, making it ideal for different packaging preferences and market requirements. This gummy filling machine can easily adapt to round, square, or customized container shapes, ensuring stable feeding, precise filling, and tight sealing. Whether for metal cans requiring seaming or plastic bottles with pressed caps, the line delivers perfect compatibility and high-speed performance.

Suitable Products:

The Gummy Cans Filling Seaming Machine Line is widely used across various granular and confectionery industries, offering accurate filling and reliable sealing for different types of products. It is perfectly suitable for soft gummy candies, vitamin gummies, jelly candies, and chewy sweets, ensuring each piece is handled gently without deformation. Beyond gummies, this machine is also ideal for nuts, trail mix, dried fruits, raisins, cranberries, beans, and pet food—providing stable performance and consistent weight control for all granular materials. The advanced weighing and rotary filling system ensures every can is filled precisely and sealed hygienically, maintaining product freshness and appearance.

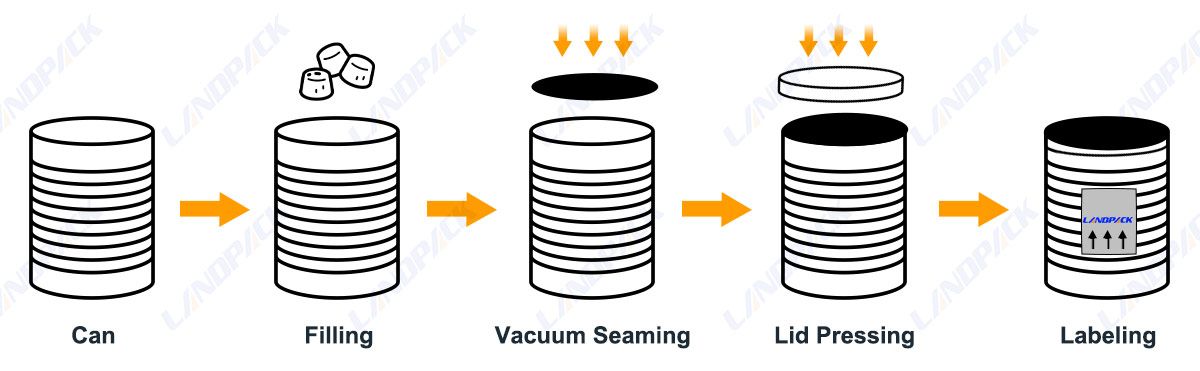

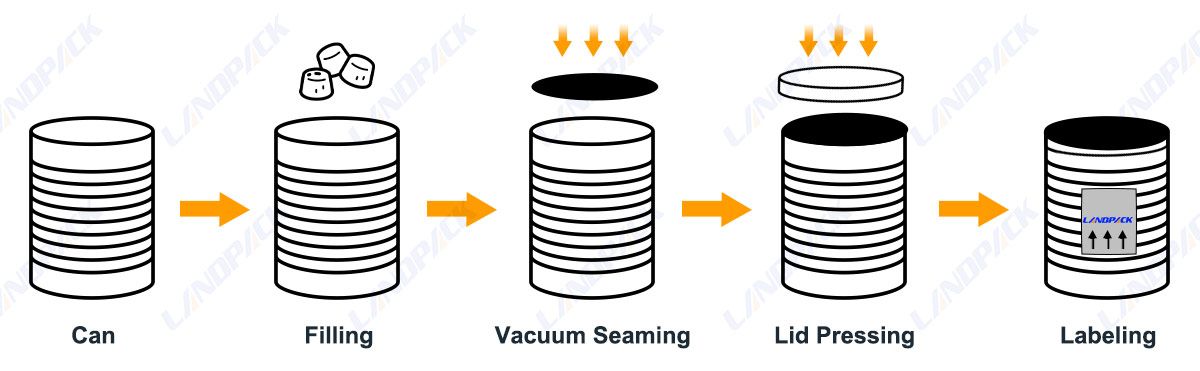

Workflow:

1. Bottles/Cans Feeding: Empty cans or bottles are transferred to manufacturing lines in an organized manner, and are ready for filling.

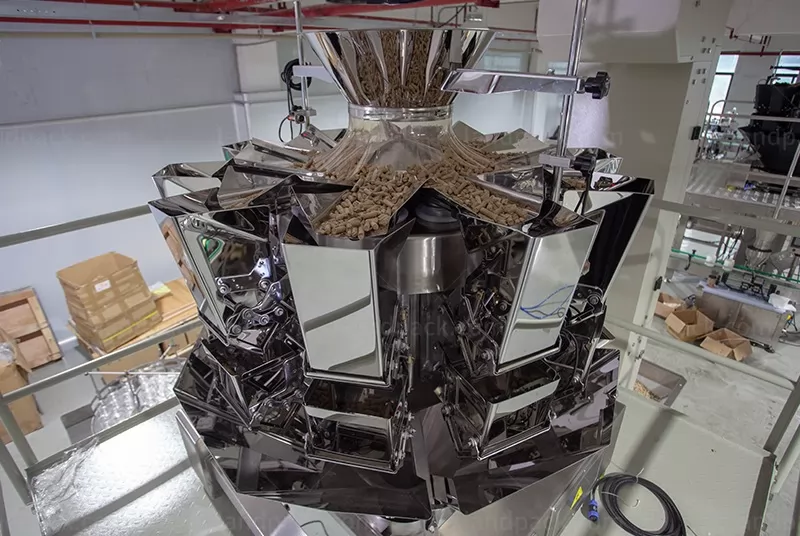

2. Weighing: This system accurately measures every Gummy's dose using a multi-head electronic weigher, which ensures an exact and consistent quantity of the product.

3. Rotary Filling: Gummies are gently filled into each can through a rotary filling system that prevents damage or sticking, maintaining the shape and quality of every gummy.

4. Cans Seaming: When filled, the cans are sealed using an automated seaming machine. This provides an airtight and tamperproof closure for a long shelf-life.

5. Plastic Lids Pressing: To provide additional security, lids made of plastic are pressed automatically onto sealed cans to give them an attractive and professional appearance.

6. Bottles/Cans Labeling: The labels are accurately applied to each bottle or can to ensure a neat display and clear information on the product for display in retail shops.

7. Finished Collecting: The completed and labeled cans are neatly collected at the end of the line, ready for boxing or further packaging.