Application:

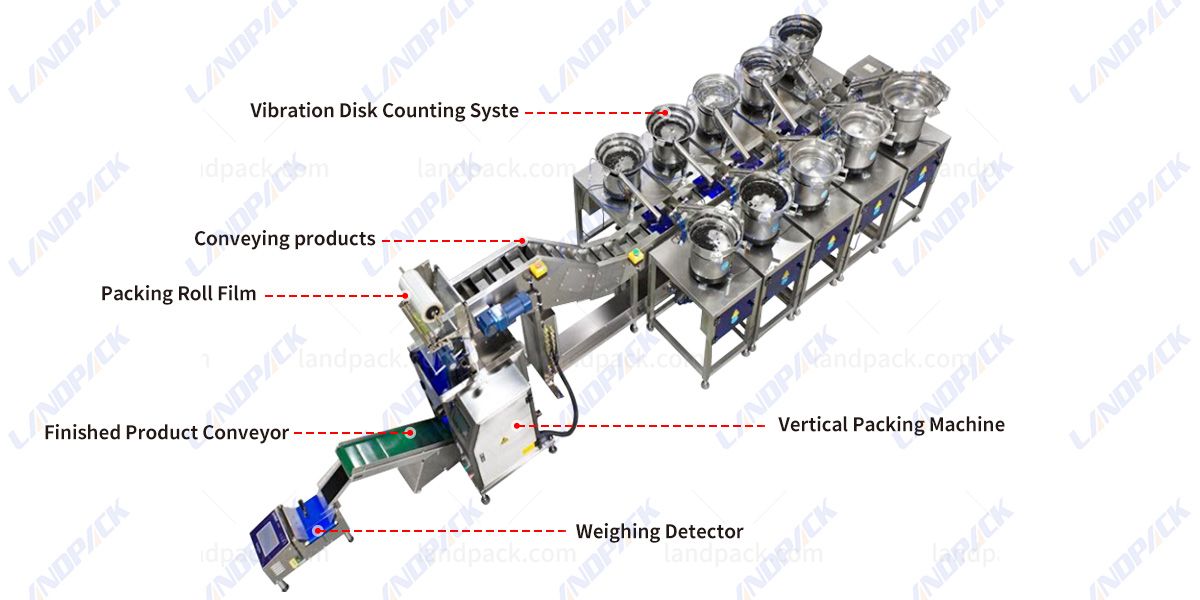

The machine is ideal for packaging various gummy products such as fruit gummies, vitamin gummies, collagen gummies, and functional gummies. It accurately counts and fills gummies into pillow pouches, back sealing pouch, ensuring consistent quantity and excellent product presentation.

The machine is widely used in the confectionery and health supplement and nutraceutical industry The machine is able to combine speed as well as precision and smooth handling to preserve the original shape, texture and quality, while also supporting various packaging formats that are suitable for bulk and retail production.

Package Type:

This machine is mainly designed for bag-type packaging, including pouches, back sealing pouches, flat pouches, and sachets. These flexible pouch styles are widely used for small granular products such as candies, nuts, tablets, and gummies. The laminated film materials (PET/PE, OPP/CPP, or PET/AL/PE) ensure strong sealing, moisture resistance, and extended shelf life.

Suitable Products:

The 10-Bowl Vibrating Feeder Counting and Packing Machine is suitable for a wide range of small granular or piece-type products. It is able to handle items like candies capsules, tablets, gummys, beans chewing gum, seeds and many other solid pieces that are uniform. The vibratory feeding system guarantees an uninterrupted flow of the product, without clogging or breaking, and precise counting assures exact portions for every packaging.

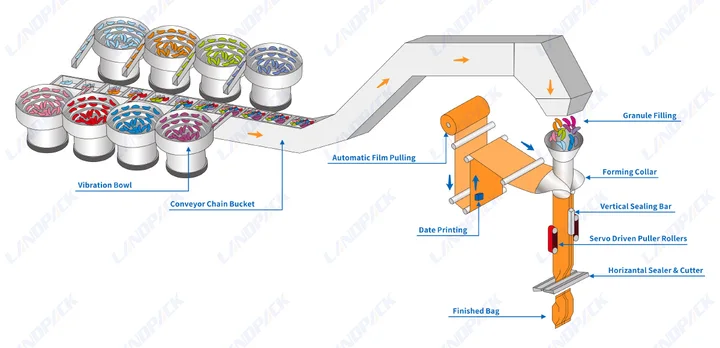

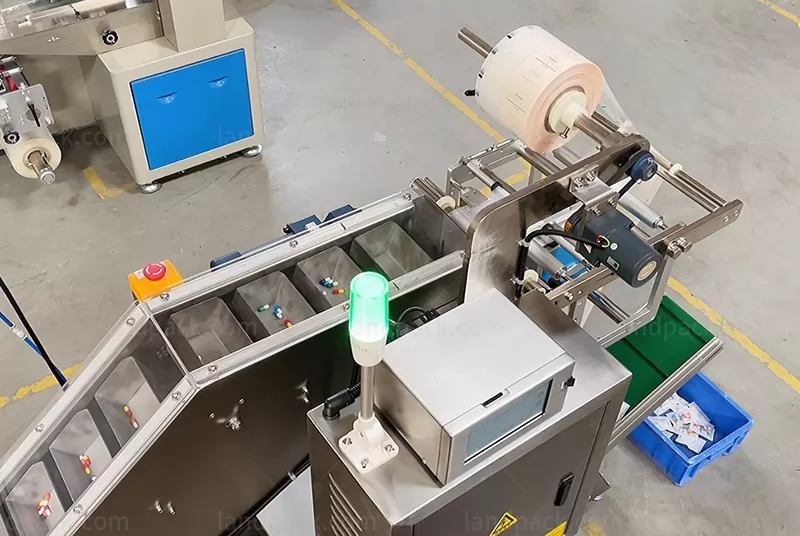

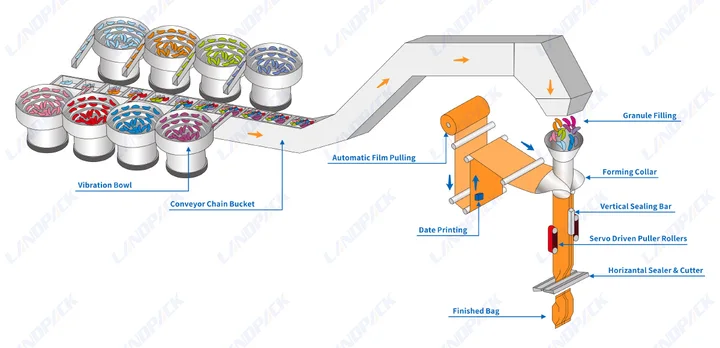

Workflow:

1. Gummy Feeding

2. Gummy Counting

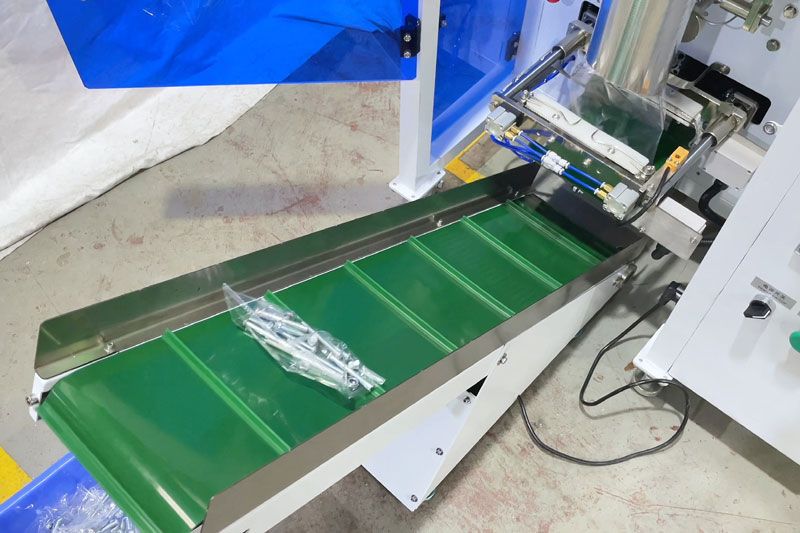

4. Bag Foming

5. Filling

6. Sealing