Application:

This automated filling and sealing line handles 6 types of granular snacks like gummies or nuts. It precisely fills tin cans, then uses advanced vacuum nitrogen flushing and sealing technology. This process ensures an extra-long shelf life, delivering premium, preserved quality for your diverse snack products.

Package Type:

This line is specifically engineered for tin cans (metal canisters, plastic cans), utilizing a robust vacuum nitrogen flushing and sealing process to ensure an ultra-long shelf life for granular products like nuts and gummies.

Suitable Products:

Our automated filling line is engineered for high-precision packaging of premium snacks, starting with delicate gummies and crunchy nuts. Beyond this, its multi-product capability is ideal for a vast range of granular and solid items, including: candies and confections, dried fruit pieces, coffee beans, loose-leaf tea, cereals & granola, rice & beans, small pasta shapes, seeds & spices, pet food kibble, desiccant packets, etc. This system offers versatile, high-speed filling for up to six different materials into airtight tin cans, utilizing vacuum nitrogen flush and sealing technology to guarantee long-lasting freshness and superior product quality.

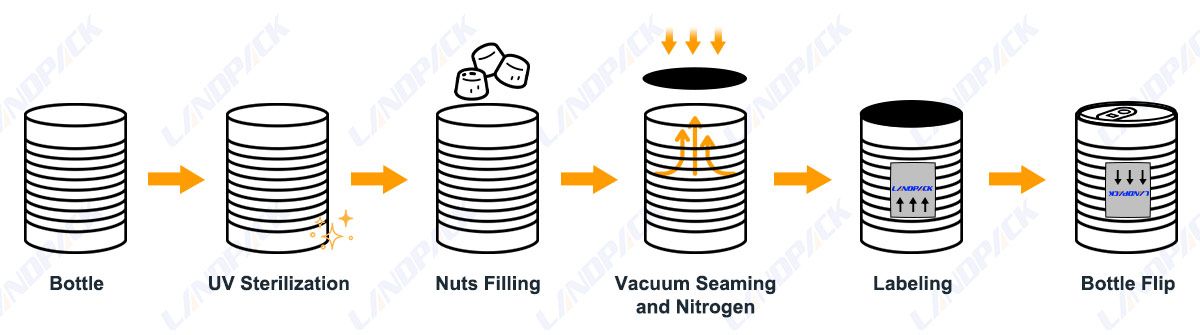

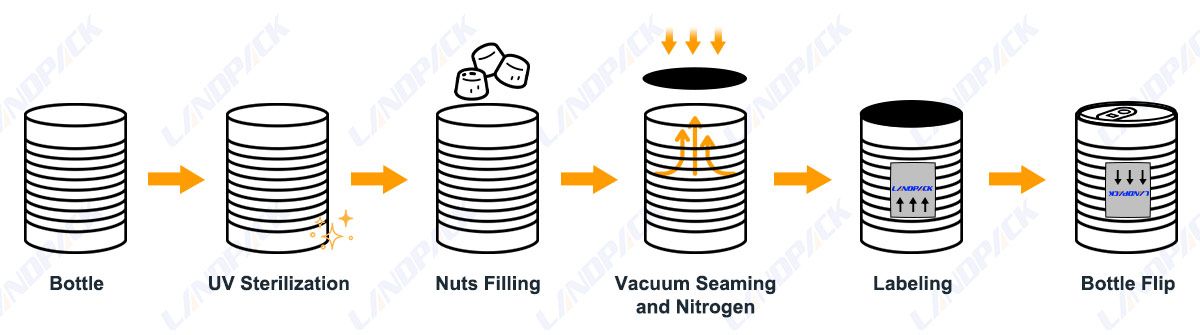

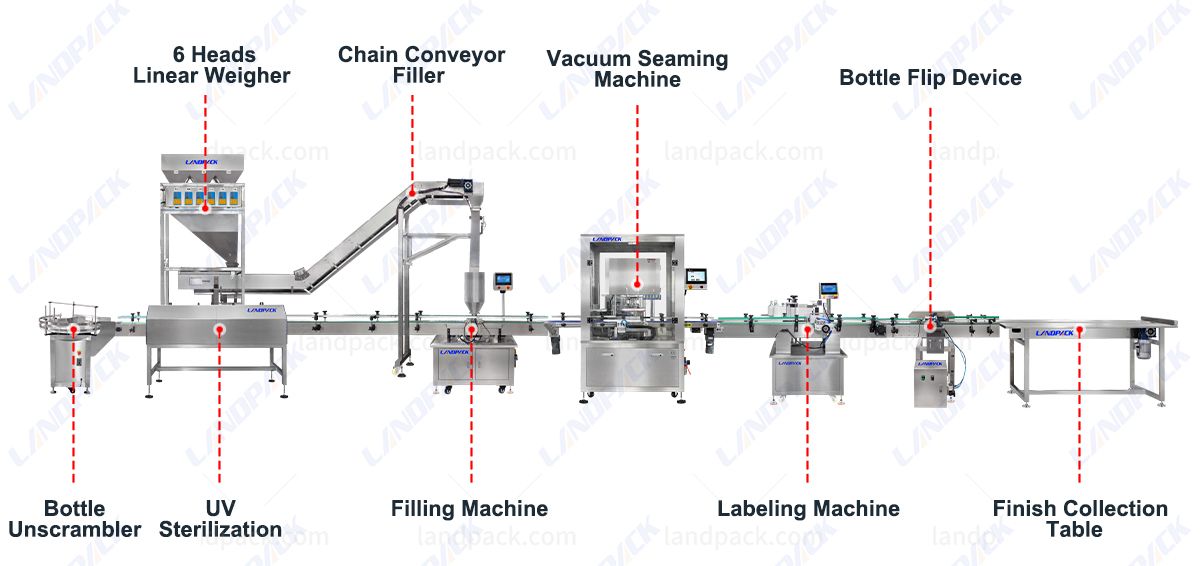

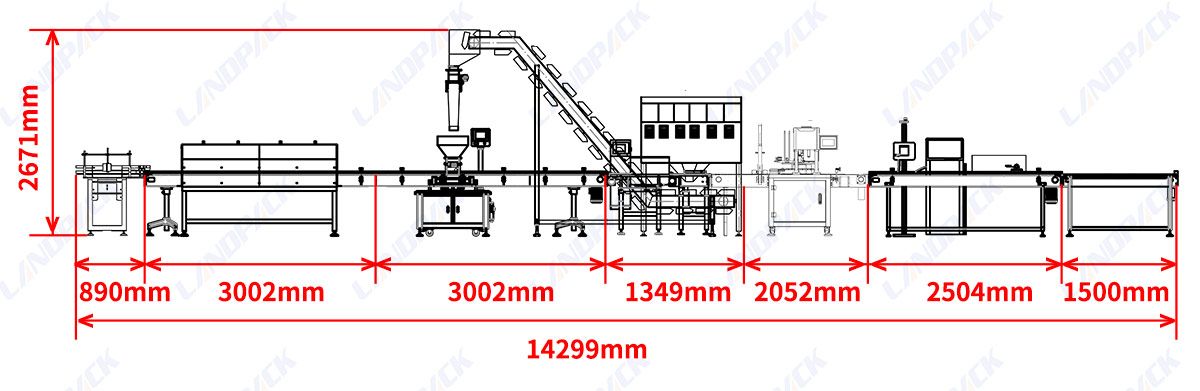

Workflow:

1. Bottle Unscrambler: Automatically sorts and aligns empty tin cans from bulk supply onto the conveyor belt in a single file.

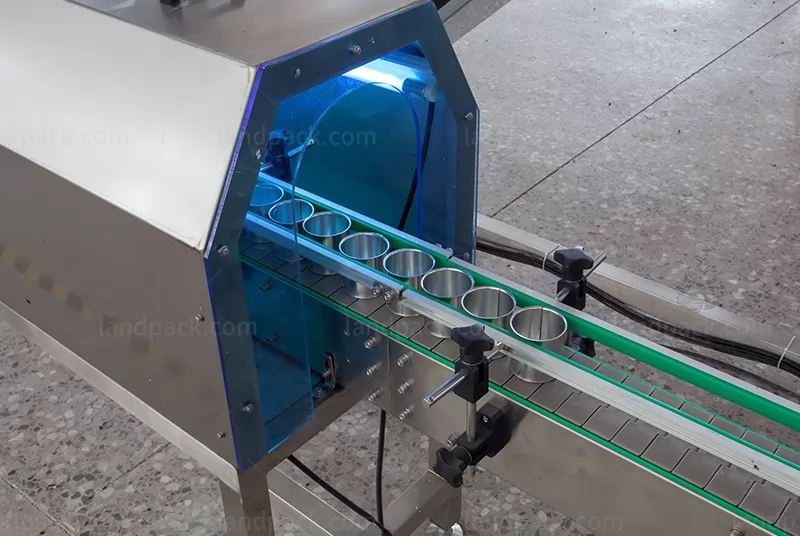

2. UV Sterilization Channel: Empty containers pass through this tunnel, using UV light to ensure a sterile environment for food safety and a longer shelf life.

3. 6 Heads Linear Weigher for weighing mixed-gummies: Precisely measures and combines the six different granular products into the exact target weight for consistent batches.

4. Straight Type Nuts Filling Machine: The straight-line filler gently and precisely dispenses the weighed mixed granules into the aligned tin cans.

5. Vacuum Seaming and Nitrogen Filling Machine: Removes oxygen (vacuum), flushes the can with nitrogen, and hermetically seals the lid to guarantee long-term freshness.

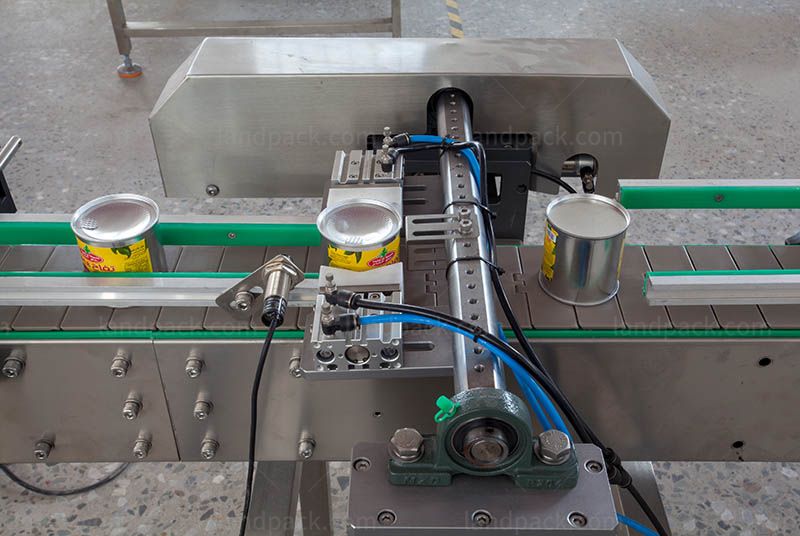

6. Round Bottle Labeling Machine: High-speed unit accurately applies pre-printed labels to the curved surface of the sealed cans for retail presentation.

7. Bottle Flip Device: Inverts the sealed cans to ensure contents are settled and to allow for a final seal inspection.

8. Finish Can Collection Table: The finished, labeled, and sealed products accumulate here for easy manual or automated transfer to final case packing.