Application:

Landpack's honey filling machine is developed for flexibility and precision, which makes it the perfect solution for cosmetic, food and medical industries. Built to handle high-viscosity items without drips, this machine can be used as filling machines for honey jars and a filling machine for honey bottles and can be used with a wide variety of containers, including glass containers, plastic bottles and metal cans. With a capacity that can reach 60 bottles/min, this sturdy filling machine for liquids is not only ideal for raw and processed honey, but it is also extensively used to package syrups, jams made from fruit, tomato paste, and other daily chemical products, guaranteeing an efficient and reliable quality for your manufacturing line.

Package Type:

This honey filling machine is compatible with a variety of packaging formats, including bottles, jars, and cans. It supports common plastic (PET/HDPE), glass, and metal containers. It can handle round or square shapes with different neck openings (narrow-mouth bottles and wide-mouth jars), making it suitable for flexible filling line setups.

Suitable Products:

This machine can be used for a range of viscous to liquid products that are commonly employed in beverage and food packaging. It can handle all kinds of smooth sauces to sweet and sticky spreads to flowing beverages along with edible oils. It's ideal for the continuous, clean filling of different viscosities. This makes it a versatile choice for multiple-product lines.

- Sauce Category: Sauce, Coffee Sauce, Honey, Jam

- Beverage Category: Juice, Tea Drink, Energy Drink, Plant-based Milk

- Condiment & Oil Category: Vinegar, Olive Oil, Sesame Oil, Syrup

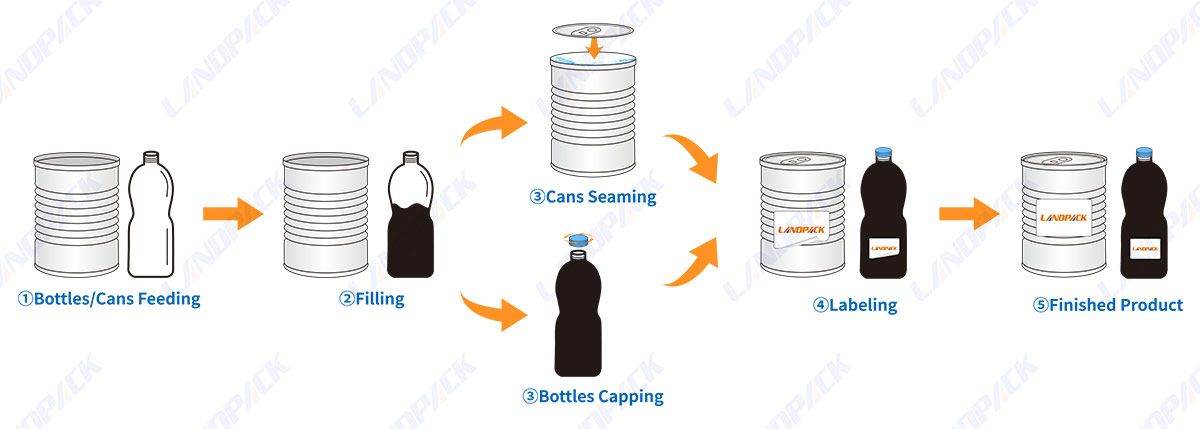

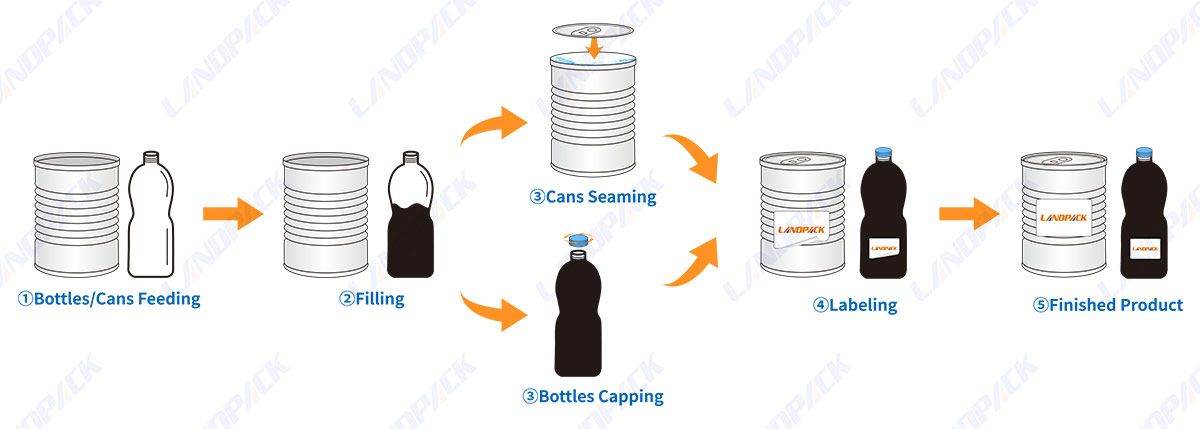

Workflow:

1. Bottles/Cans/Jars Feeding: Automatically conveys empty containers to the station, ensuring smooth feeding for the honey jar filling machine or bottle line.

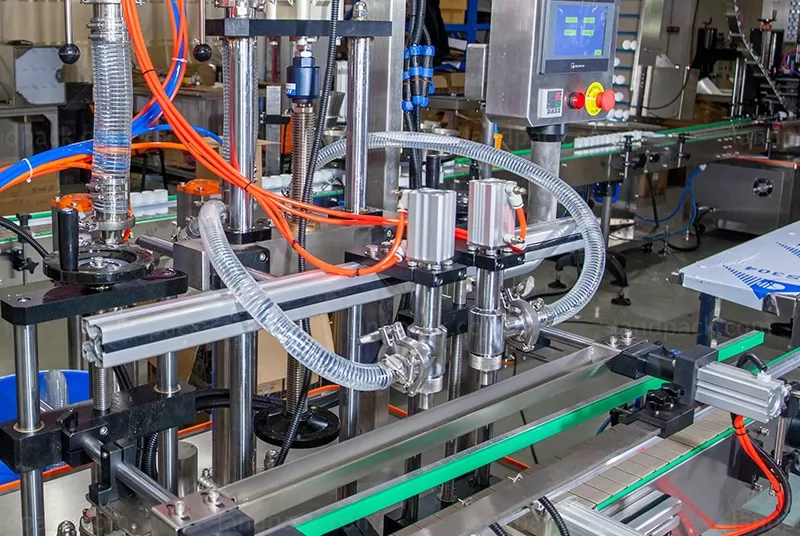

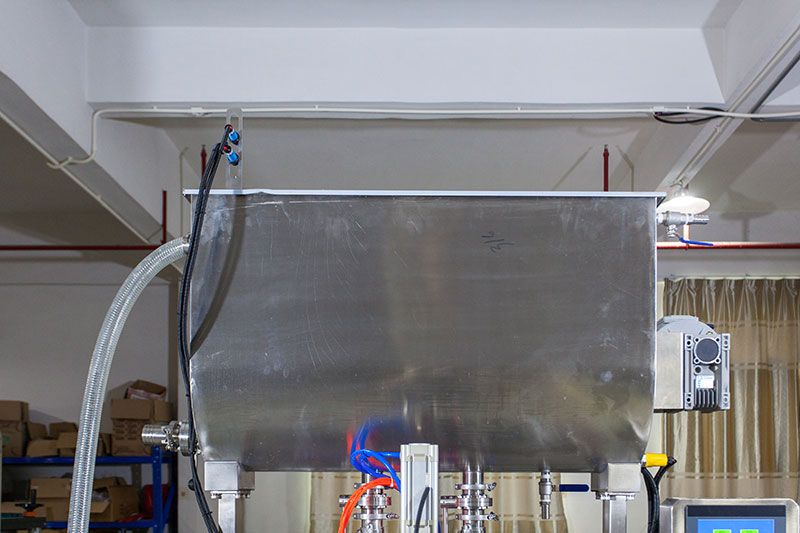

2. Liquid Material Filling: The honey filling machine precisely dispenses high-viscosity liquid at up to 40 bottles/min, ensuring drip-free accuracy.

3. Cans Seaming / Bottles Capping: Securely seals the containers to preserve freshness, capable of handling both bottles capping and cans seaming operations.

4. Labeling (Optional): Accurately applies brand labels to the containers, adding a professional finish to the honey bottle filling machines output.

5. Finished Product Output: Transports the sealed and labeled goods to the collection table, completing the liquid filling machine cycle efficiently.