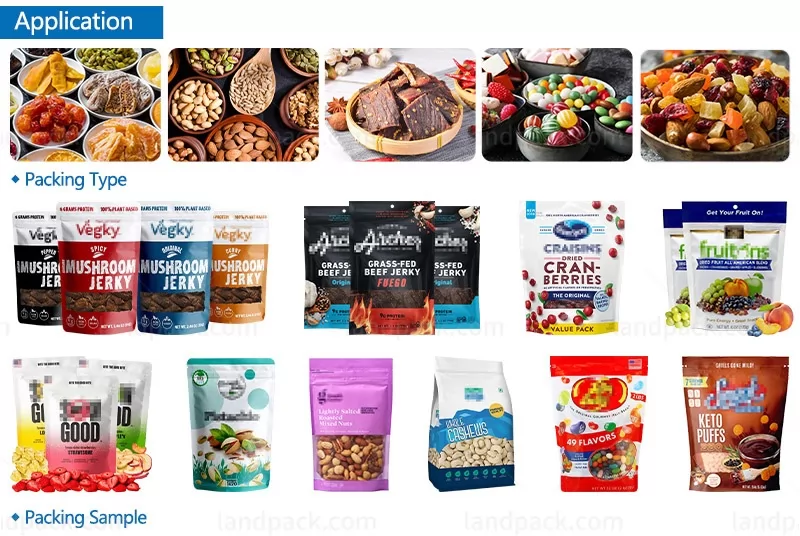

Application:

The mini doypack beef jerky packaging machine is suitable for various industries that require single-station premade bag packaging. It supports different pouch types such as stand-up pouches and flat pouches, and integrates automatic bag feeding, accurate weighing, filling, sealing, and output into one compact system - perfect for products requiring flexible, hygienic, and attractive packaging.

Package Type:

The Mini Doypack Packing Machine is designed to work with a wide range of premade pouches, offering great flexibility for different packaging styles. It is compatible with stand up pouches, flat pouches, and M shape/gusset pouches to increase volume capacity. It also perfectly handles standard doypacks and other premade pouches with or without zipper.

Suitable Products:

The Landpack Mini Doypack Packaging Machine is extremely versatile and was designed to handle a wide range of goods from many industries.

- Food items like nuts, beans and pulses, jerky, and dried fruits may be packaged with precision and precision with the intention of preserving their freshness and flavor.

- Pharmaceutical and health, it's ideal to pack medicinal granule tablets, capsules and vitamin granules using high-end hygiene and precision.

- Daily Necessity, able to pack pet treats, food, as well as pet products and desiccants. This will ensure that the appearance of an attractive seal.

No matter what kind of product, be it solid or smaller in size, the mini doypack packaging machine is a flexible, efficient and dependable packaging solution.

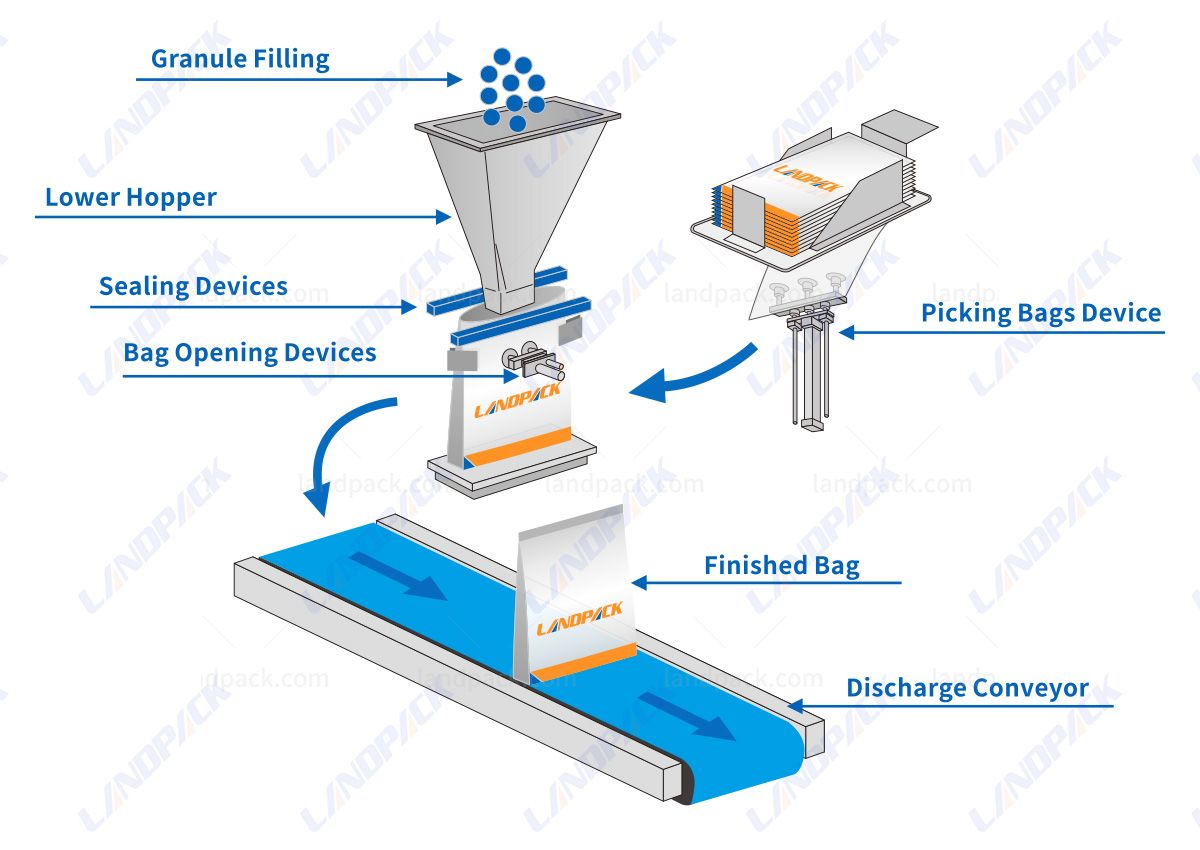

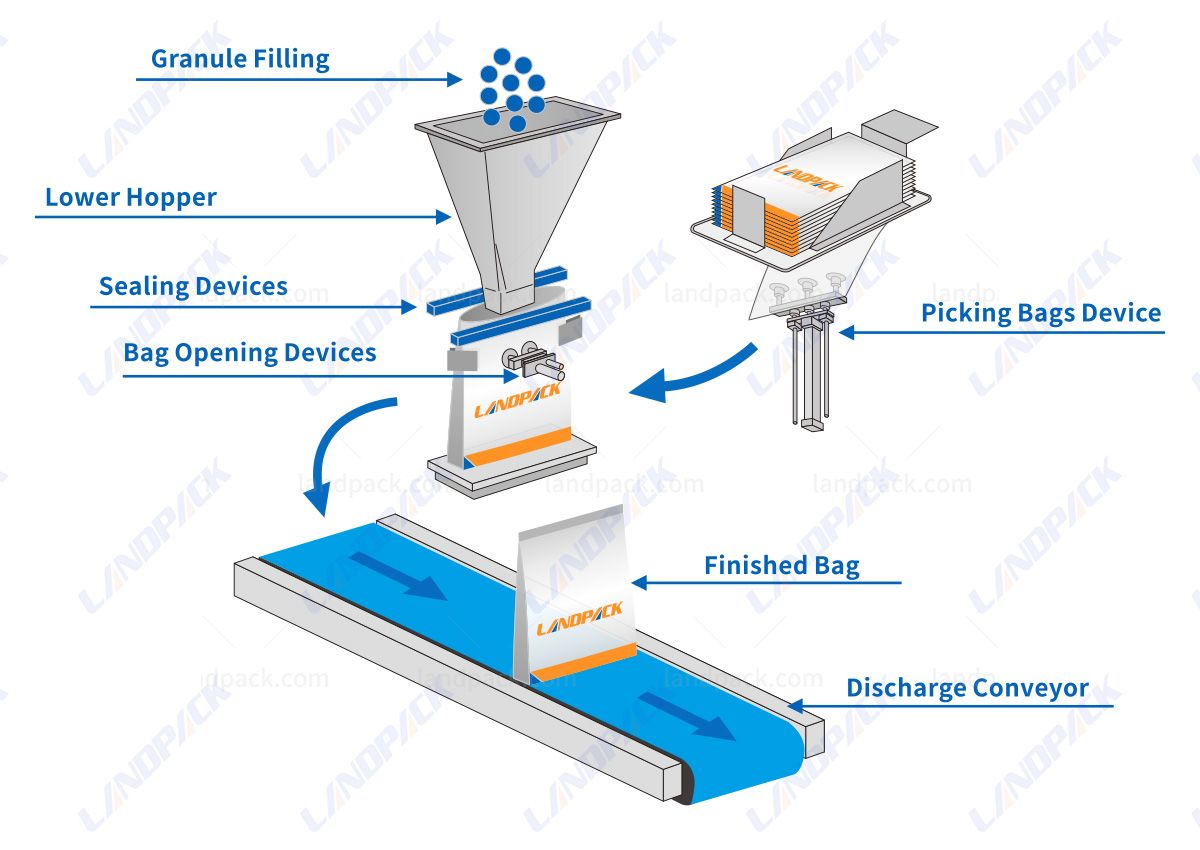

Workflow:

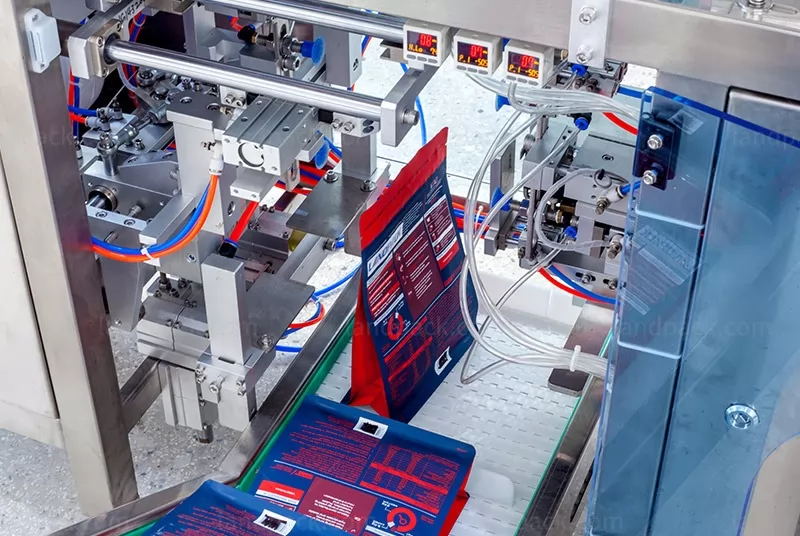

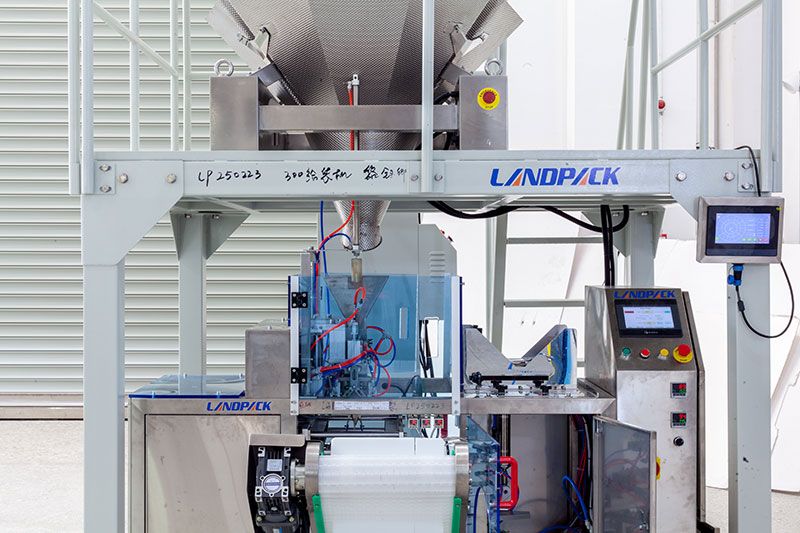

The working process of the Mini Doypack Packaging Machine is simple and efficient:

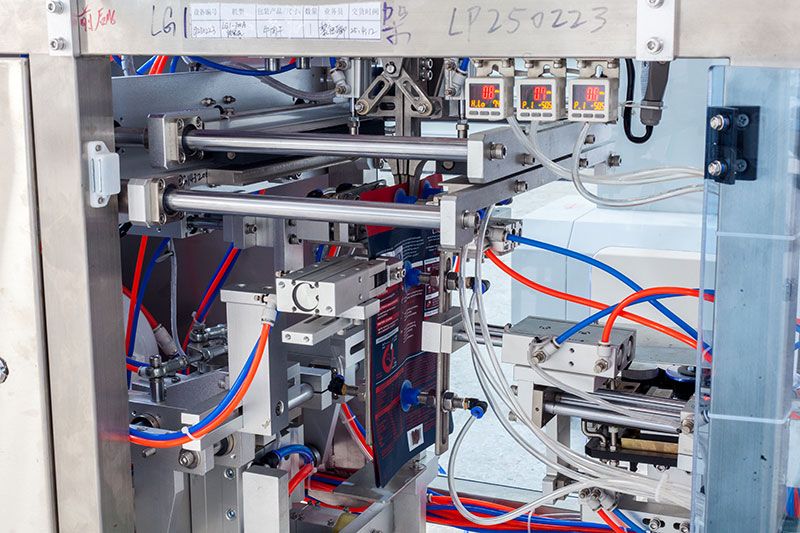

1. Picking Bags: The machine automatically selects each pouch from the magazine of the bag.

2. Bag Opening: Air blasts or mechanical arms can open the bag to make it ready for filling.

3. Granule Filling: Granules (such as jerky, beans, nuts, and more) are precisely dispensed inside the bag once it has been opened.

4. Lower Hopper: The hopper is lowered gently to guarantee the smooth and neat filling of the product without spills.

5. Sealing: Sealed tightly bag's top to ensure that the product remains fresh and safe.

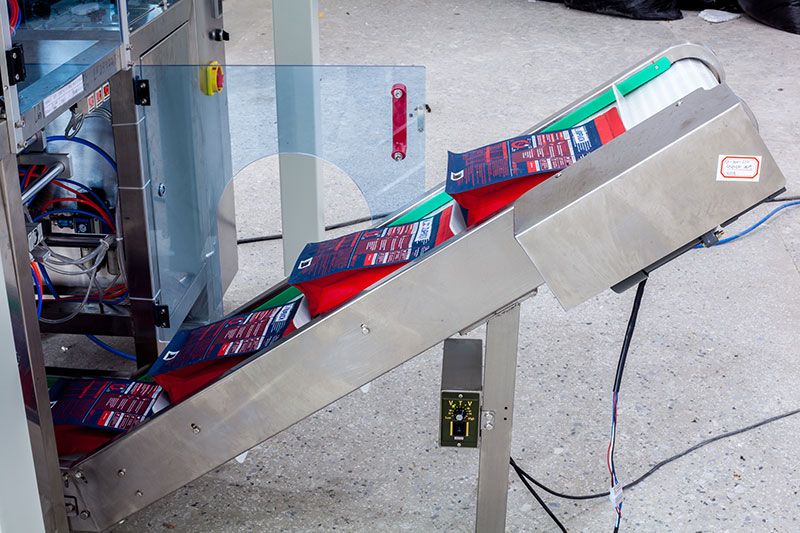

6. Completed Bag Output: The sealed pouch is discharged on the conveyor and is ready to be secondary packed or delivered.