Nowadays, product packaging is everywhere. What kind of packaging to choose and what machine to use for packaging? Many people are still struggling with this issue in the early days of starting a business. In reality, you will find that the most important packaging tool for products is the packaging machine, which has a very wide range of applications and can be adapted to the packaging of various granular, block, strip, liquid, solid, and other items. It is widely used in all walks of life. Such as the food industry, pharmaceutical industry, daily chemicals, hardware accessories, etc. The difference between the vertical packaging machine and the doypack packaging machine is that the supply cylinder of the packaged materials is set inside the bag-making machine, and the bag-making and filling of materials are carried out in the vertical direction from top to bottom. To put it simply, the vertical packaging machine makes bags and packages them at the same time, while the bag packaging machine uses premade bags for packaging. Can you tell the difference between manufacturers who want to buy packaging machines? If you don't know whether to choose a vertical packaging machine or a doypack packaging machine, let's talk about the difference between a vertical packaging machine and a doypack packaging machine:

Product features of vertical packaging machine:

1. All stainless steel exterior decoration, is in line with GMP specifications. All are made of 304 steel.

2. Equipped with safety protection to meet enterprise safety management requirements. The operation is safe and enterprises can use it with confidence.

3. It has the function of setting an automatic output alarm, and can also set the function of automatically displaying the packaging operating speed. The computer controller is a brand-new product, using high-quality CPU chips and an imported switching power supply. All functions are operated by buttons and displayed digitally.

4. The vertical packaging machine can set the bag length by computer, eliminating the pain of changing gears and adjusting the bag length. The touch screen can store the packaging process parameters of a variety of different products and can be used at any time without resetting when changing products.

5. The vertical packaging machine has high accuracy, with an error within 0.5mm within the speed range of 50-100 bags/minute.

6. Using an intelligent thermostat, the temperature control is accurate and the sealing is beautiful and smooth.

7. An optional rotary coding machine can be used to print batch numbers and shelf life in 1-3 rows. This packaging machine and metering configuration can automatically complete the entire packaging process of metering, feeding, filling and bag making, date printing, inflation (exhaust), and finished product transportation, and automatically complete counting.

8. It can be made into pillow-shaped bags, bags with hanging holes, etc. according to customer needs.

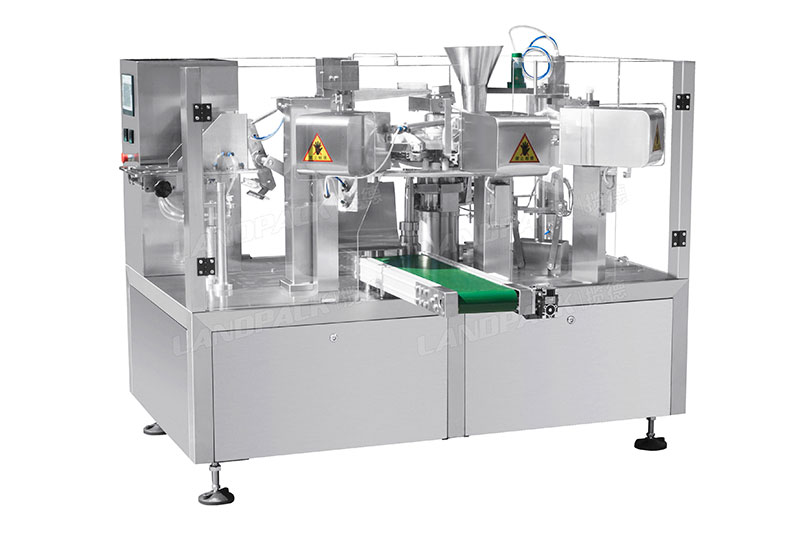

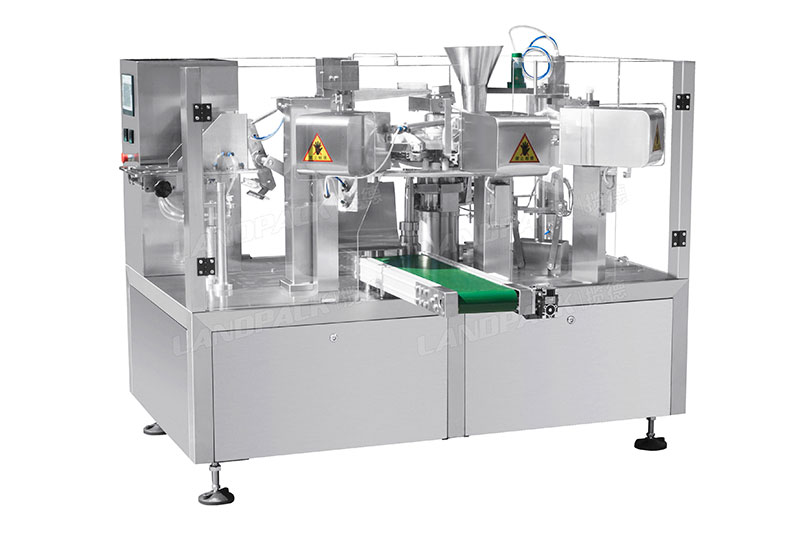

Product features of doypack packaging machine:

1. Fully automatic feeding, automatic bag feeding, coding, bag opening, quantitative measurement, filling, heat sealing, and finished product output.

2. The doypack packaging machine is an automated production equipment that directly replaces manual packaging production, allowing enterprises to realize packaging automation, thereby improving production efficiency and significantly reducing production costs.

3. The parts of the doypack packaging machine that come into contact with materials or packaging bags are made of stainless steel or other materials that meet food hygiene requirements to ensure food hygiene and safety and comply with food hygiene standards.

4. It adopts imported PLC system control + touch screen HMI human-machine interface system control, which is convenient and simple to operate. The use of stable cam mechanical transmission technology ensures stable operation of the equipment, low failure rate, and low energy consumption. At the same time, it adopts a high-end circuit structure to realize electromechanical integration.

5. The packaging machine implements functions such as self-automatic detection and information feedback. If there is no packaging bag or the packaging bag is not opened during production operation, the detection device will control neither filling nor sealing. The operating status will be displayed in real time and the fault alarm will shut down. Save packaging materials and raw materials, ensuring the environment of the packaging site and pollution of raw materials.

6. It has a wide range of packaging and can package: liquids, pastes, powders, granules, and solid materials. You only need to choose different metering and filling devices according to different materials.

7. The packaging bag has a wide range of adaptability and can be packaged in prefabricated bags and paper bags made of multi-layer composite films such as single-layer PE, PE composite materials, CPP composite materials, aluminum foil, and other materials.

8. The loss of packaging materials is low. This machine uses premade bags. The packaging bags have perfect patterns and good sealing quality, thus improving the product quality.

9. Quickly change packaging bag specifications, and the width of the robot device can be adjusted easily and quickly, which is convenient and simple, saving time and effort.

10. With the horizontal bag feeding method, the bag storage can store more packaging bags, has lower requirements on bag quality, and has a high bag dividing and bag loading rate.

Thank you for reading, please get in touch with us if you have any inquiries.

LANDPACK would be your reliable supplier of packing machines.

If you have any questions about the machine, feel free to contact us or leave your machine inquiry on our website, our sales managers and engineers will be here to support you and provide you with a suitable packing solution.

You could contact us by our website address or phone number, our sales managers will contact you in time and give you professional suggestions. And our engineers are willing to help you to solve the machine problem and teach you one step by step on video calling.