1. The system employs intelligent weighing technology to ensure precise measurements during the packaging process.

2. It operates at high speeds while maintaining stability, resulting in efficient production.

3. The use of #304 stainless steel for food filling components ensures hygiene and durability.

4. Equipped with a Siemens PLC and a touch screen, the system is easy to operate and configure.

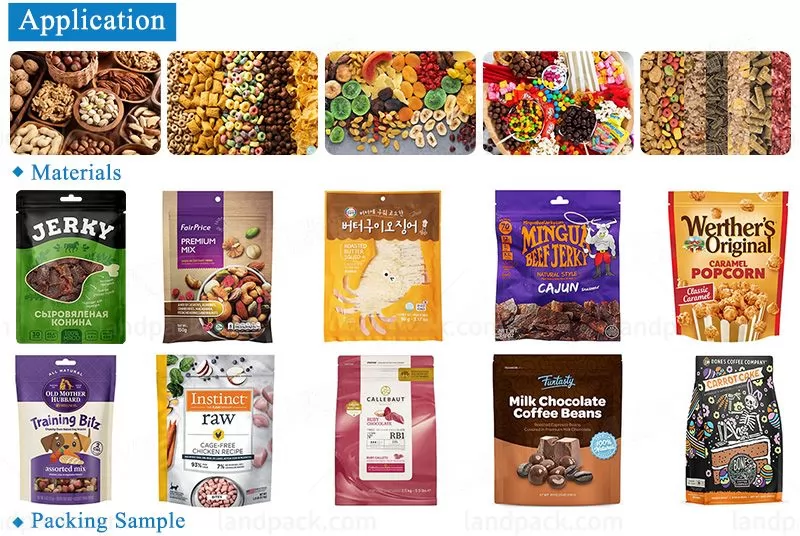

5. While it's well-suited for the food industry, it also finds applications in chemical, commodity, and toy industries.

6. The 110-degree customized widened automatic weigher enhances product flow, making it smoother and more shatter-resistant.

7. It accommodates different bag types and sizes, with a maximum size of 260 mm*350 mm.

8. All material contact parts feature a shockproof silicon plate, safeguarding fragile products.

9. The system boasts a 14-head, 2.5-liter multi-head weigher, ensuring high accuracy and easy attainment of target weights.

10. A retainer plate and conveyor chain support heavier and delicate products during the packaging process.

11. A desiccant dispenser keeps the interior dry to maintain product freshness.

Workflow:

1. Giving the bag

2. Open the bag

3. 14head 2.5L weigher for weighing the product with an anti-damage device protecting the raw material

4. Desicant dispenser

5. Collect hopper for raw material faster the speed

6. Retainer Plate to protect the raw material and reduce the buffer

7. Conveyor Chain for support the over 1kg heavier product

8. Tidy up the bag

9. Sealing the bag

10. Output for the finished bag