Application:

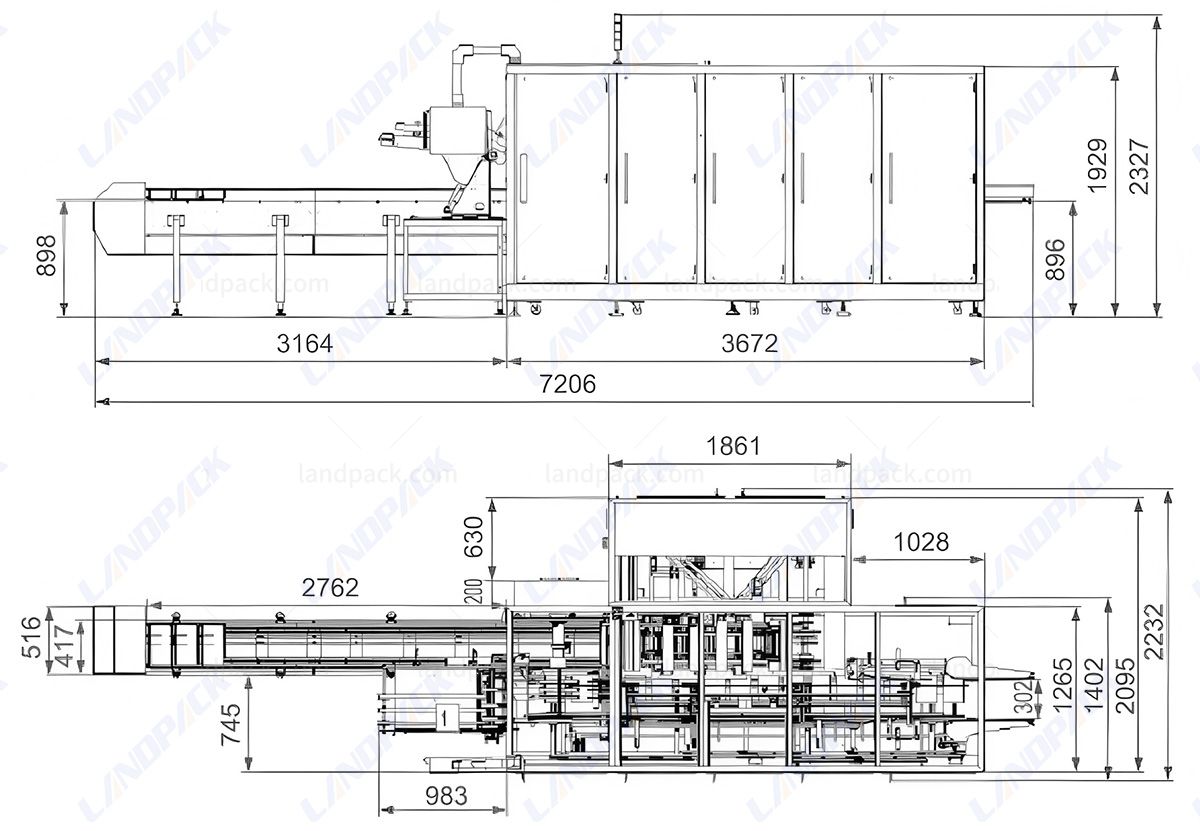

Automatic Horizontal End Load Cartoning Machine is for secondary packaging at 80–150 cartons/min, suitable for food, pharmaceutical, cosmetics, daily chemical and consumer goods industries. It automatically performs carton erecting, product grouping, horizontal end loading and carton closing for products such as sachet, stick pack, pouches, bottles, cans, and wrapped items. it can either operate independently or be integrated with packing and filling machines to create fully automated packaging lines.

Package Type:

This machine is suitable for pre-glued paper cartons such as tuck-in flap cartons, straight-tuck and reverse-tuck boxes, widely used for retail and secondary packaging applications.

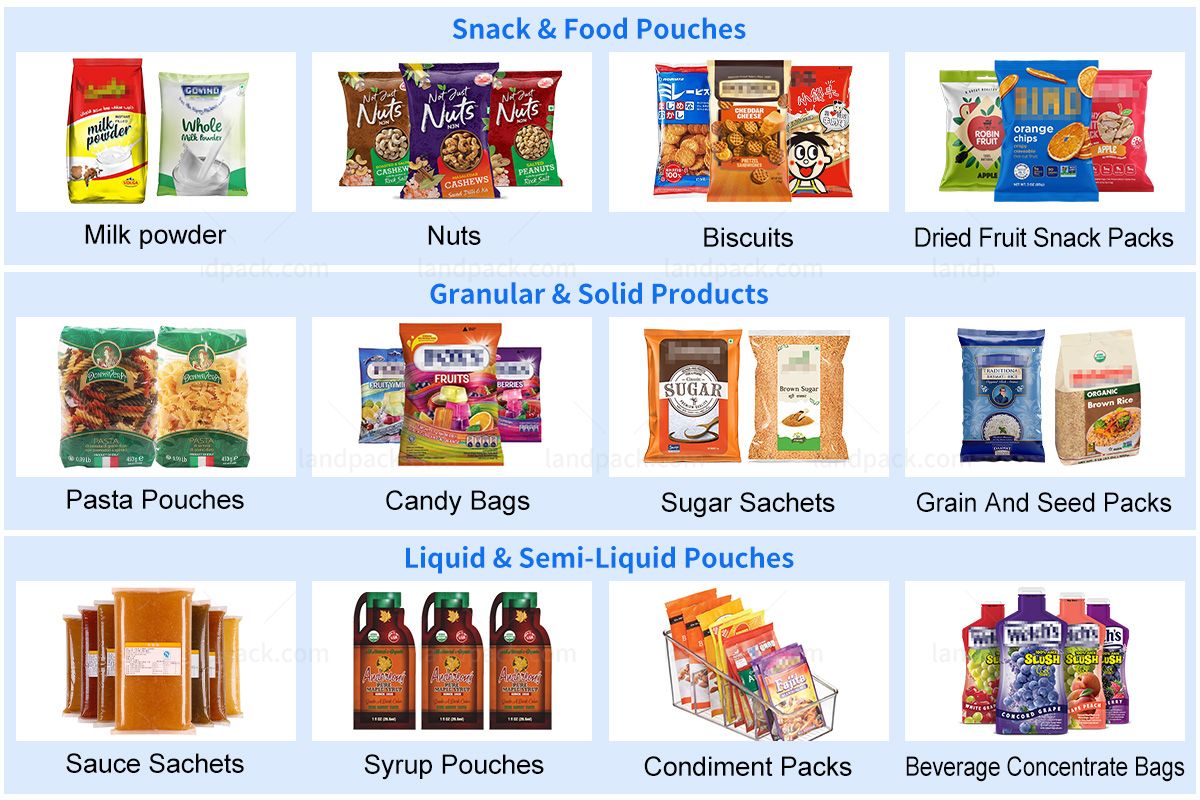

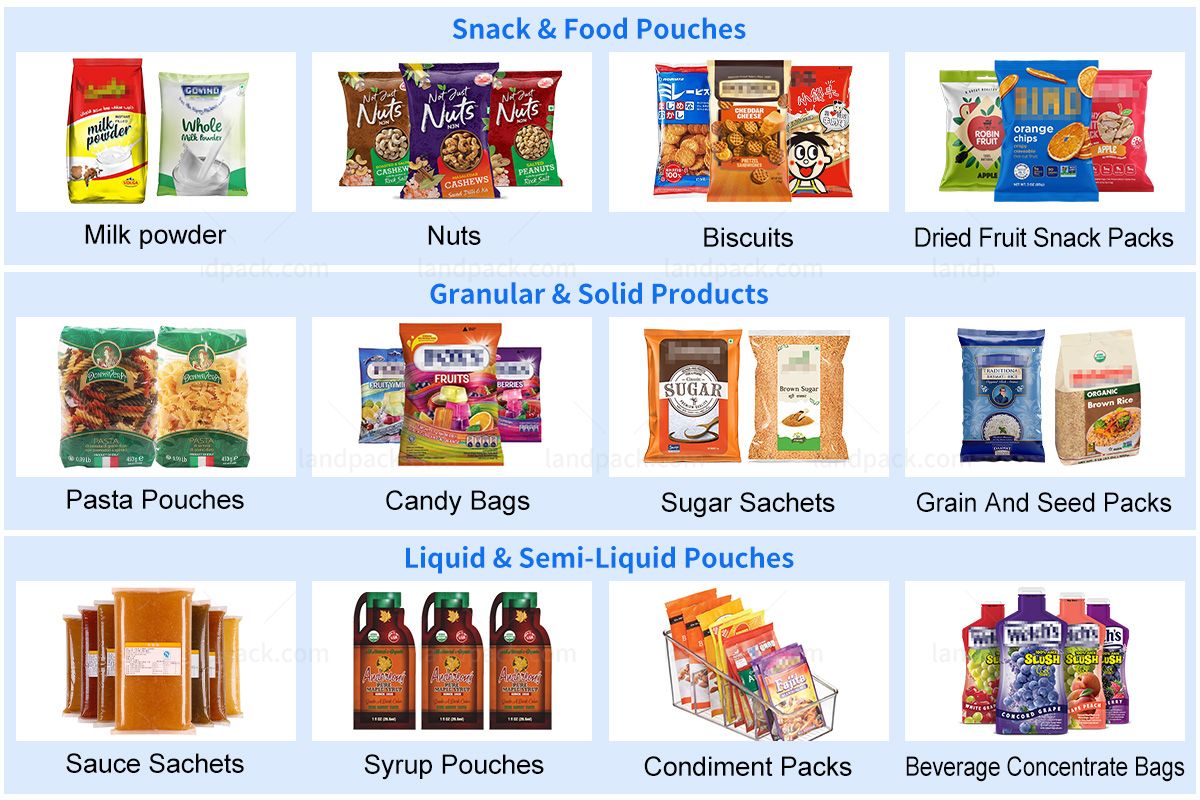

Suitable Products:

The Automatic Horizontal End Load Cartoning Machine is used in food, beverage, pharmaceutical, cosmetics, daily chemical, and consumer goods industries. It packs products such as bottles, cans, sachets, pouches, blister packs, tubes, and pre-wrapped items into cartons for retail or secondary packaging.

Workflow:

1. Carton Picking & Erecting – Pre-glued cartons are picked from the magazine and automatically opened into shape.

2. Product Feeding – Products such as bottles, cans, sachets, or blister packs are grouped and aligned for loading.

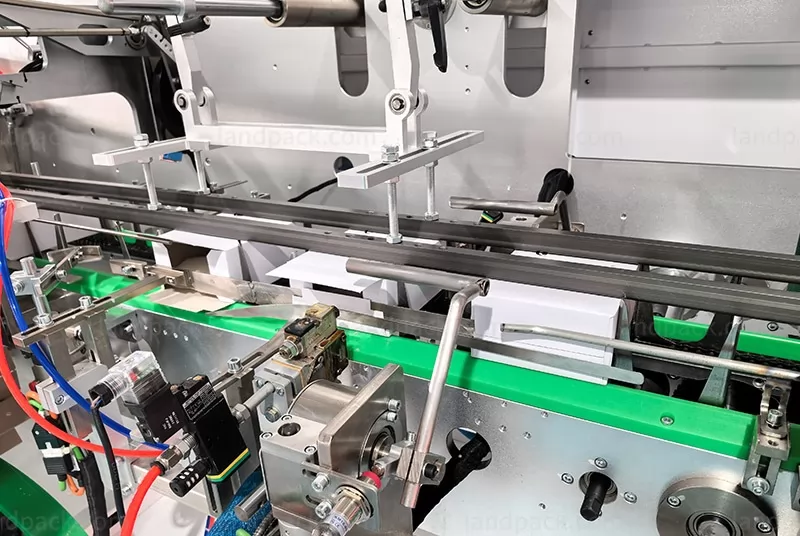

3. Horizontal End Loading – Products are pushed into the carton from the side (end-load style) precisely and efficiently.

4. Carton Closing & Sealing – The carton flaps are folded and sealed using tuck-in, adhesive, or hot-melt glue methods.

5. Discharge & Transfer – Finished cartons are discharged onto conveyors for packaging, labeling, or palletizing downstream.