Application:

This high-speed secondary packaging system operates at a capacity of 20 to 60 cartons per minute, catering specifically to the food, medical, beauty, household chemical, and retail sectors. The equipment automates the entire process—including case forming, product collation, horizontal side-loading, and final carton sealing—for various formats like sachets, sticks, bags, containers, and overwrapped goods.

Package Type:

This machine is engineered for pre-glued paper cartons, accommodating a wide range of styles including tuck-in flap cartons, straight-tuck, and reverse-tuck boxes. It is particularly optimized for gift boxes and premium secondary packaging, ensuring clean edges and precise flap alignment.

Suitable Products:

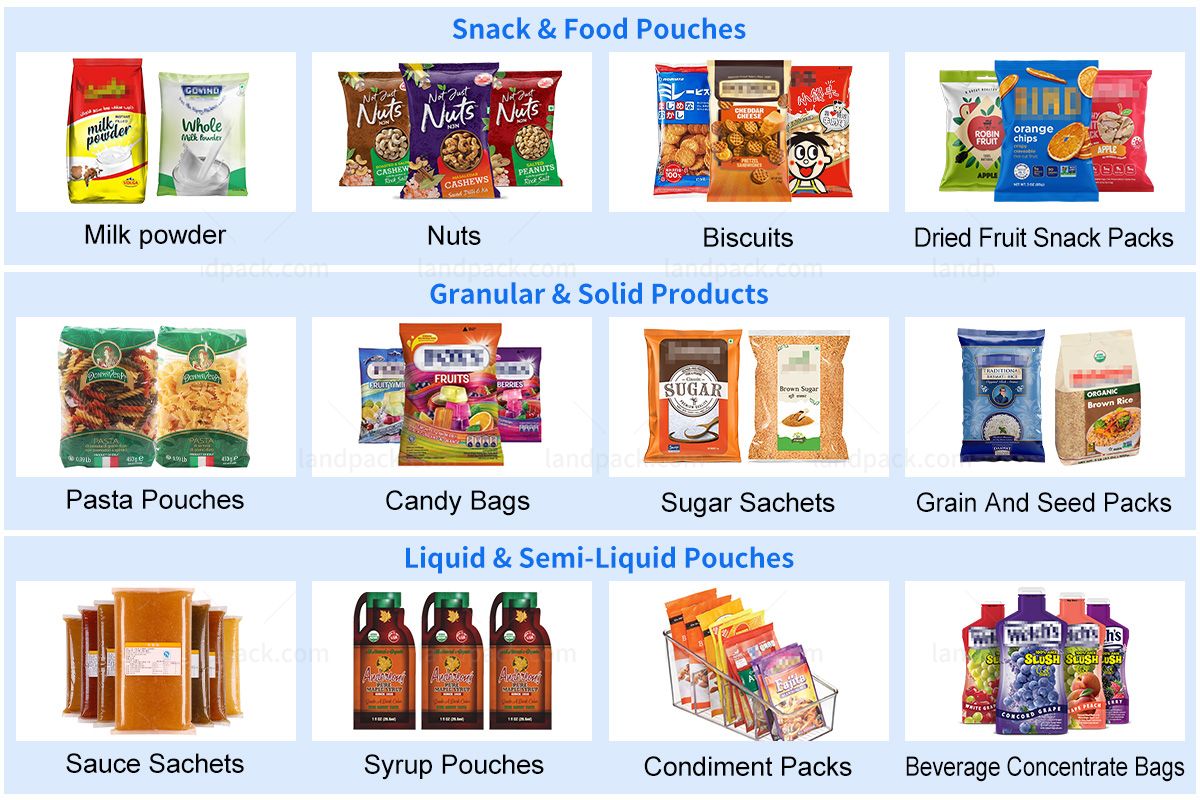

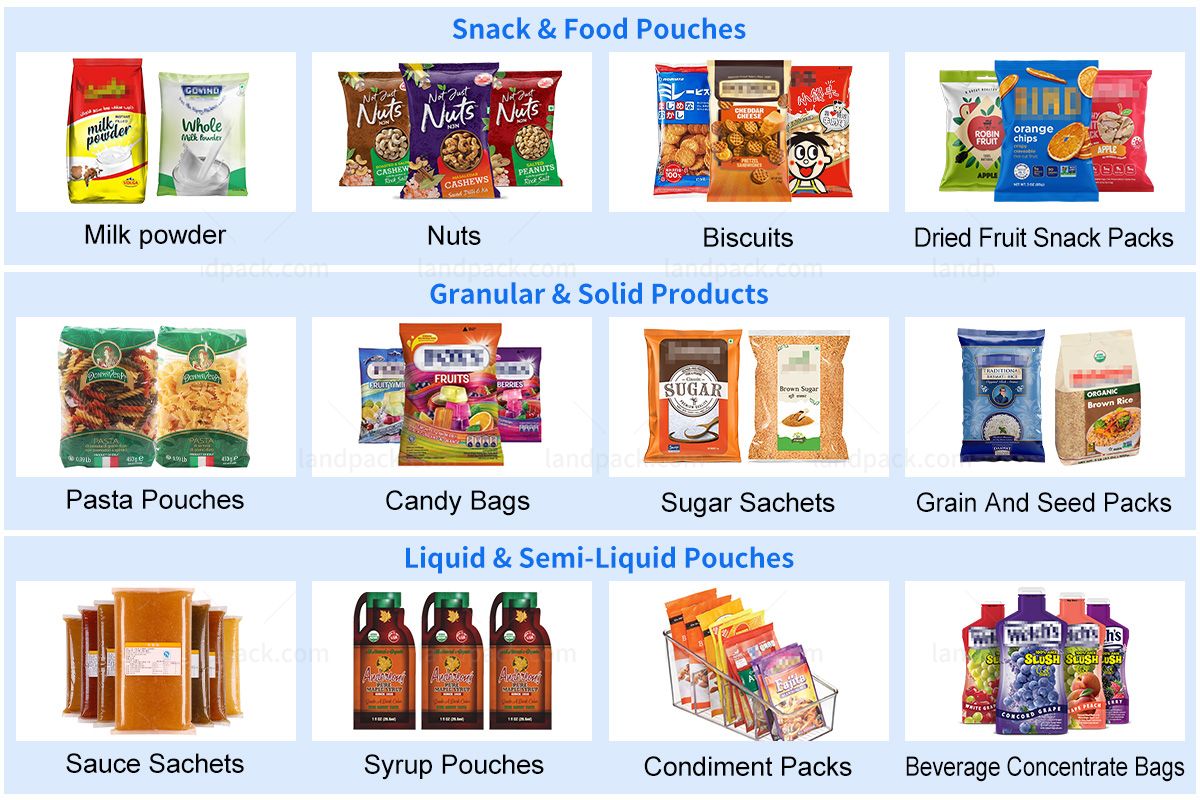

Food & Beverage: Stand-up pouches, coffee stick packs, instant noodle seasoning sachets, and snack bags.

Pharmaceutical & Health: Granule sachets, medical patches, blister cards, and syrup bottles.

Personal Care: Facial mask sheets, travel-size tubes, soap bars, and wet wipe packs.

Workflow:

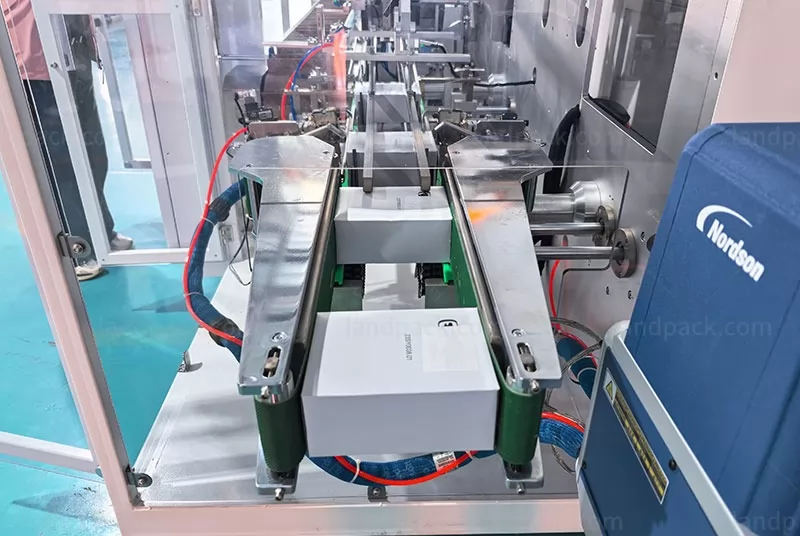

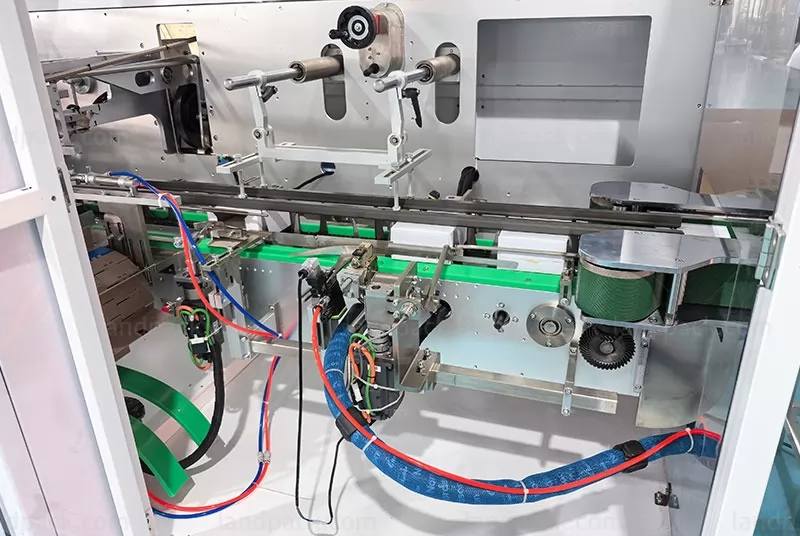

1. Suction-Feed Cartoning - The rotary vacuum arm extracts carton blanks from the magazine, snapping them into a rigid 90° structure.

2. Servo-Timed Infeed - Products are synchronized via the Clamp Belt and transferred to the loading station without jamming.

3. Lateral Insertion - A servo-driven pusher executes horizontal end-loading, ensuring zero-damage to fragile bag contents.

4. Integrated Sealing - Depending on the configuration, flaps are either tucked or precision-dotted with hot-melt adhesive.

5. Quality Outfeed - The Conveyor discharges the finished boxes for check-weighing or case packing.