Application:

The four side sealing packaging machine is suitable for granules, powders, and liquids. It guarantees flat, airtight Sachets of products such as coffee spice and nuts, dried fruits grains, tea, cosmetic masks, detergent, as well as health supplements. They provide top quality protection and attractive presentation.

Wide Application Range:

Four Side Sealing Packing Machine is extensively used to create precise and secure packaging in many industries. It's ideal to:

* Food Products:

Nuts and Seeds (almonds cashews seeds)

Coffee & Tea

Dried Fruits (raisins Mango slices Cranberries, raisins)

Spices and seasonings (pepper, curry powder chili flakes)

Grains & Beans (rice, lentils, soybeans)

* Daily Products:

Detergent Powder

Facial Mask

Desiccant Packets

* Others:

Pet Food Snacks

Agricultural Seeds

Health Supplements Powder

Packaging Style:

It is widely used in sachet, 3/4 sides sealing pouch, etc.In food products, daily needs as well as health products as well as other fields. It's easy to use and offers the professional appearance of a display.

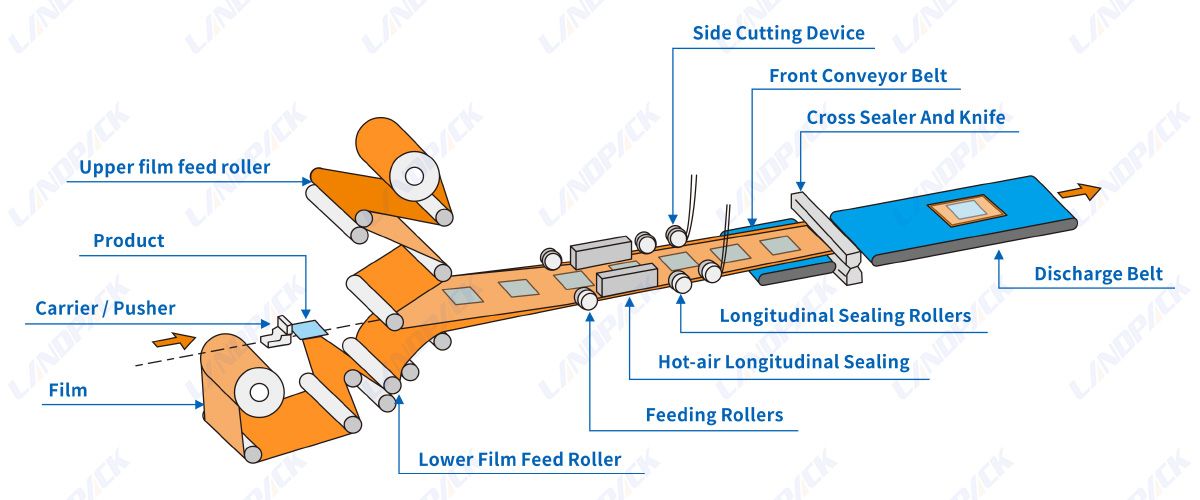

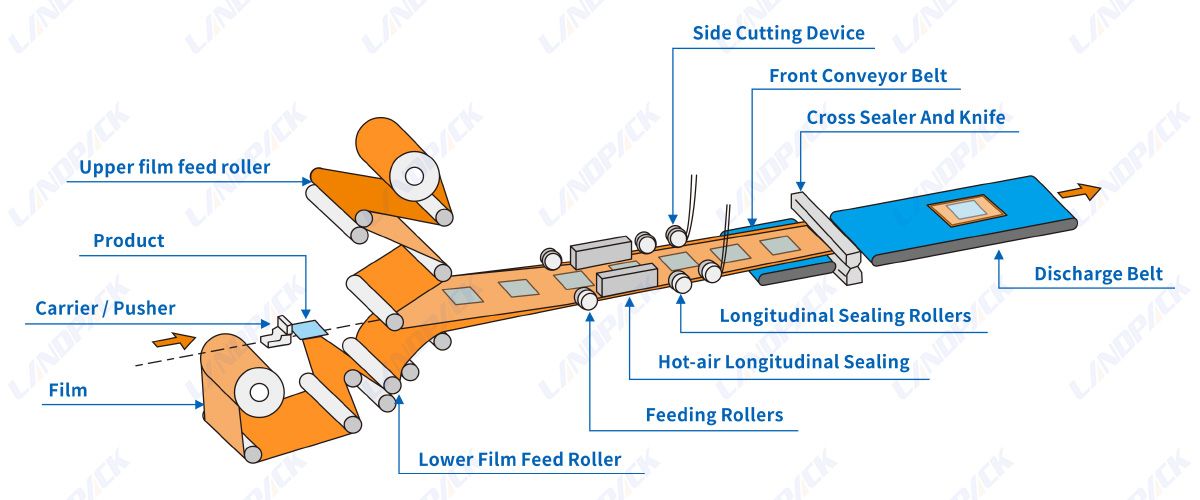

Process Workflow:

1. Film Feeding: The film is unwound automatically and then precisely inserted through the machine.

2. Marking/Printing (Optional): Date the batch or code could be printed onto the film prior to sealing.

3. Product Feeding: Products that are measured (powder and granules, as well as liquid) are dosed precisely and then incorporated in the films.

4. The first sealing (Longitudinal): Vertical sealing encases the film into a pouch.

5. Four Side Sealing: The four edges are simultaneously sealed to create flat, solid bags.

6. Cutting and shaping: Sealable sachets are cut to homogeneous sizes. This ensures clean edges and a premium look.

7. Completed Output: The final sachets are released in a timely manner to be packed for distribution, or storage.