Application:

The four side sealing packaging machine is suitable for granules, powders, and liquids. It guarantees flat, airtight Sachets of products such as coffee spice and nuts, dried fruits grains, tea, cosmetic masks, detergent, as well as health supplements. They provide top quality protection and attractive presentation.

Wide Application Range:

This Four Side Sealing Packing Machine is used extensively to make airtight, flat pouches which are simple to keep and display. It can be used for:

* Food Products:

Seasoning Powder

Instant Soup Base

Sugar & Salt

Sauce & Condiment

Instant Coffee & Milk Powder

* Daily Products:

Facial Mask

Detergent & Washing Powder

Desiccant

Shampoo & Lotion

* Others:

Veterinary & Pet Medicine Powders

Agricultural Seeds

Health Supplement

Packaging Style:

It is widely used in sachet, 3/4 sides sealing pouch, etc.In food products, daily needs as well as health products as well as other fields. It's easy to use and offers the professional appearance of a display.

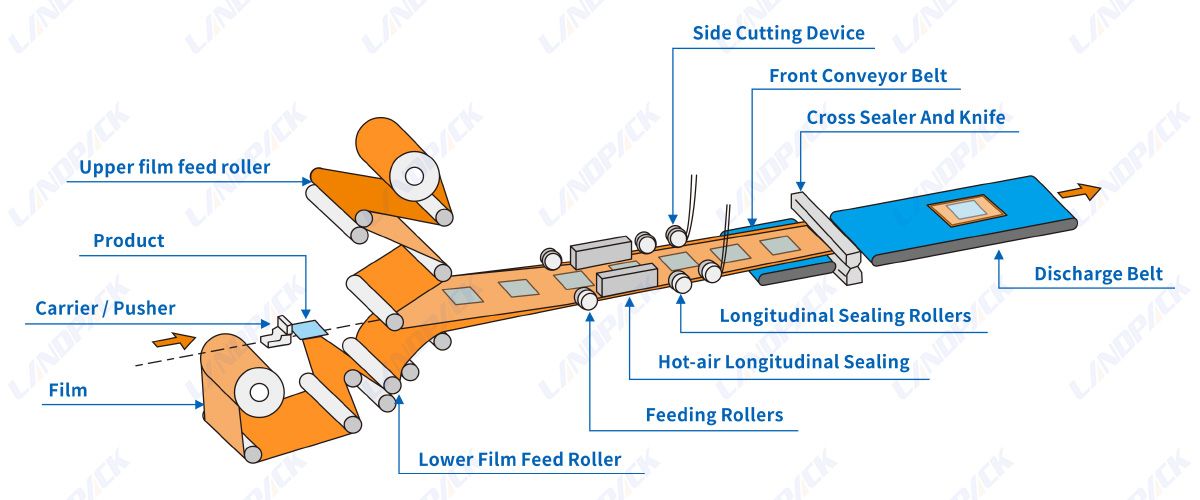

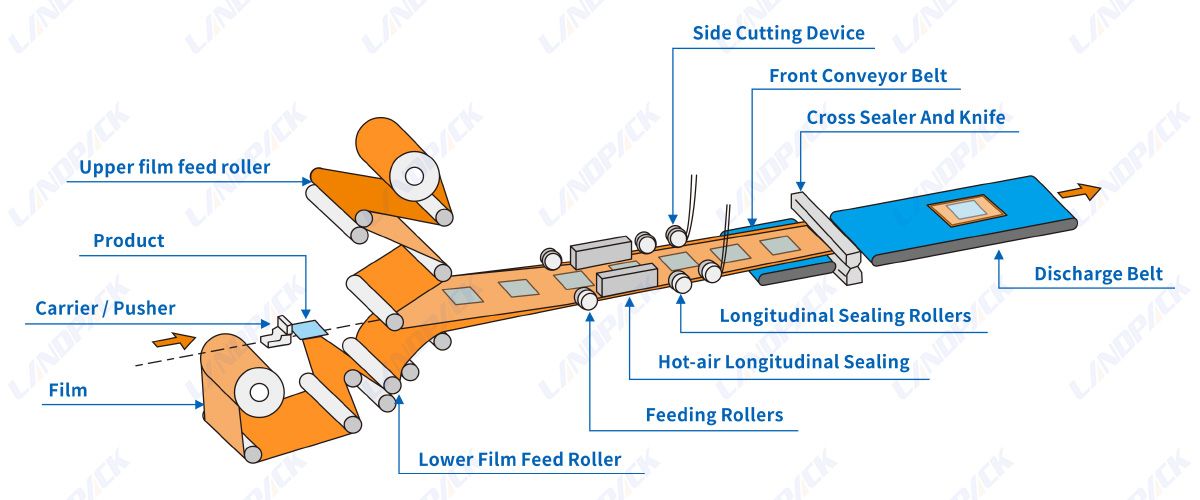

Process Workflow:

This is a fully automatic four side sealing packing machine for liquid/granule/powder products in sachets. Here's how it works step-by-step:

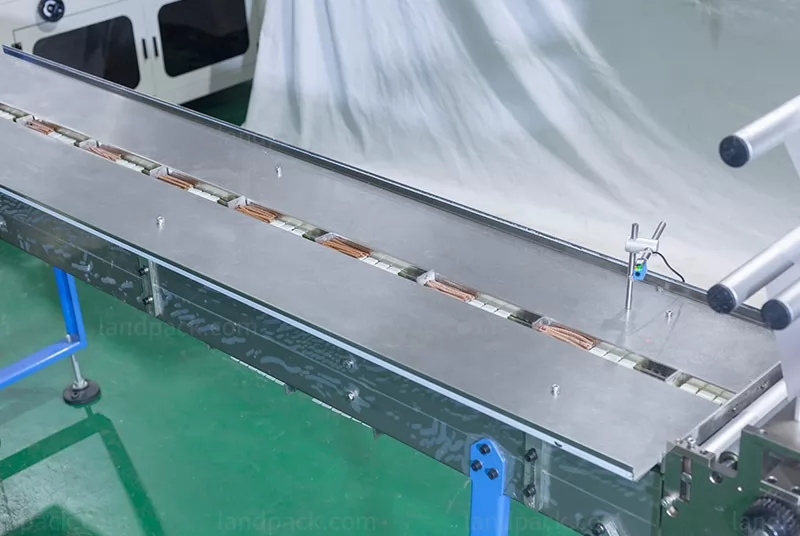

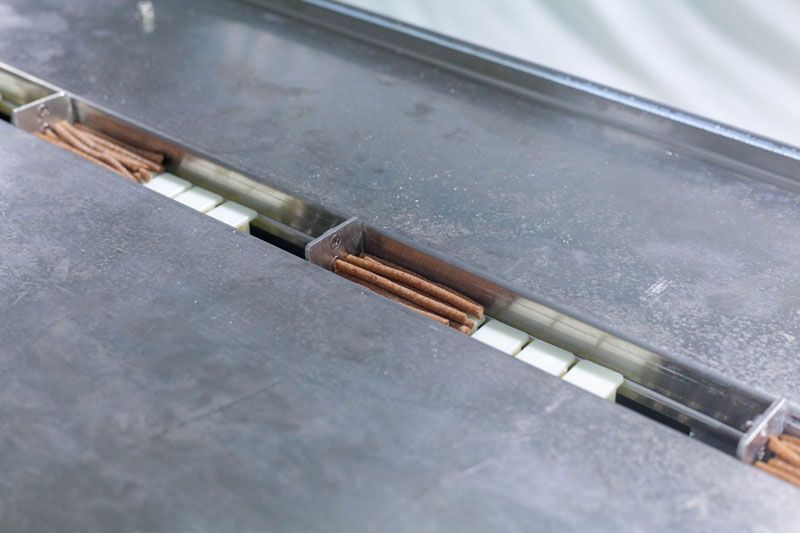

1. Film Feeding: This machine is able to feed flat films

2. Bag Formation: This bag is shaped into a bag, with precisely cut edges to seal the bag on four sides.

3. Product Filling: Product are precisely dispensed in the bags.

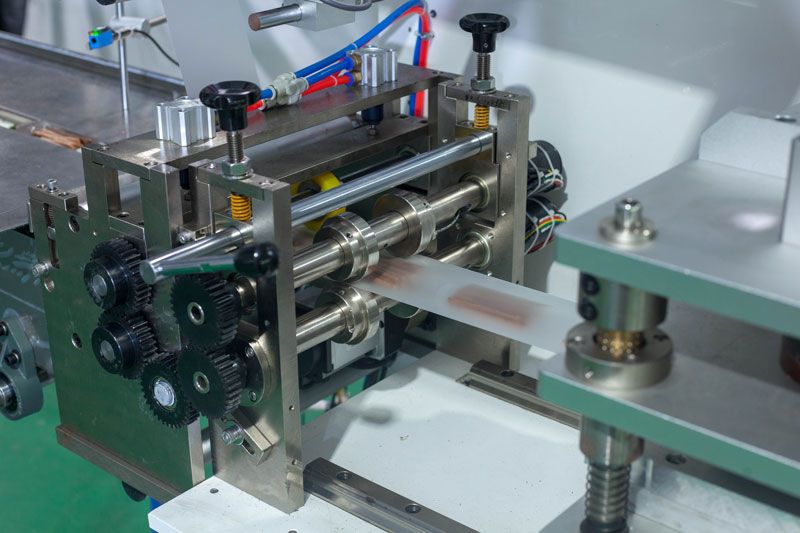

4. Bag Sealing: All four sides of the bag have been sealed to guarantee an airtight bag.

5. Final Product Outlet: Sealed bags are discharged to an easy-to-use conveyor for packaging or for later processing.