Application:

A Four-Side Seal Packaging Machine is a type of automatic packaging equipment that produces pouches with all four edges sealed. Two long side seals (left & right), plus top and bottom seals, it's ideal for items where airtightness, moisture protection, or a tidy appearance are important.

Suitable Industry:

The four-side seal packing machine is versatile. Some common application areas and product types:

Food & Beverages - Snacks, powder (coffee, milk powder, spices), sauces, pastes, sweets, condiments.

Pharmaceuticals / Health - Single-dose sachets, powders, tablets, herbal granules, medical patches.

Daily Chemicals / Cosmetics - Shampoos, creams, lotions, small trial packs, detergents.

Hardware / Non-Food - Small parts, patches, hardware components; products needing dust-proof or moisture-proof packaging.

The machine can handle products in various forms: powder, granules, liquids or pastes, etc.

Packaging Style:

It can be found widely used for sealing pouches of various sizes with four sides sealing mechanisms. Furthermore, its easy operation provides professional-looking displays.

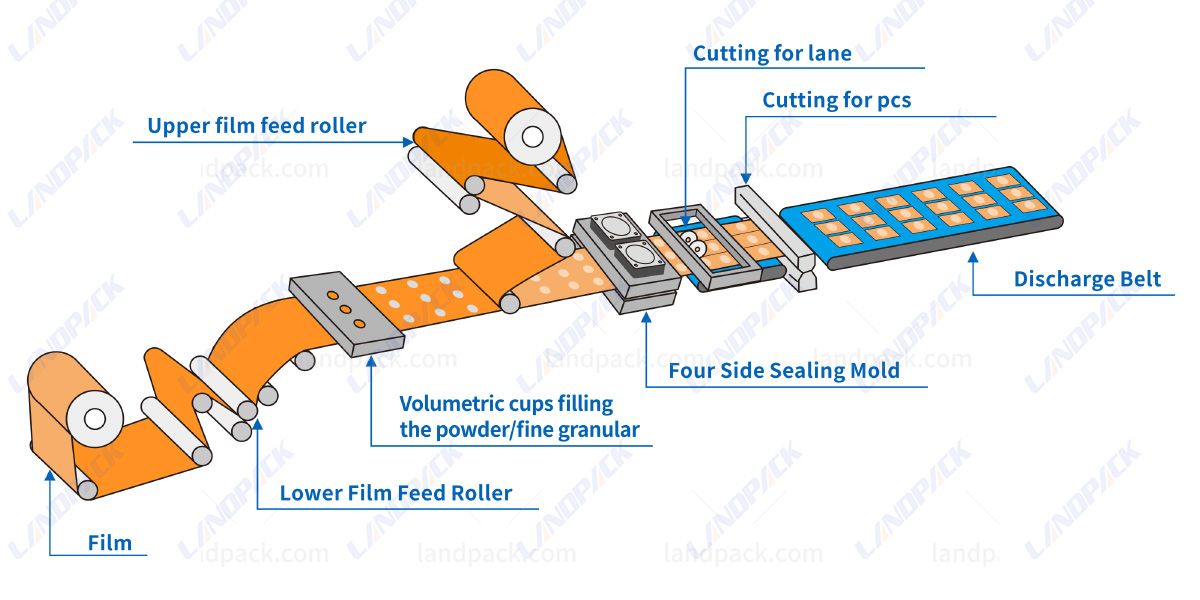

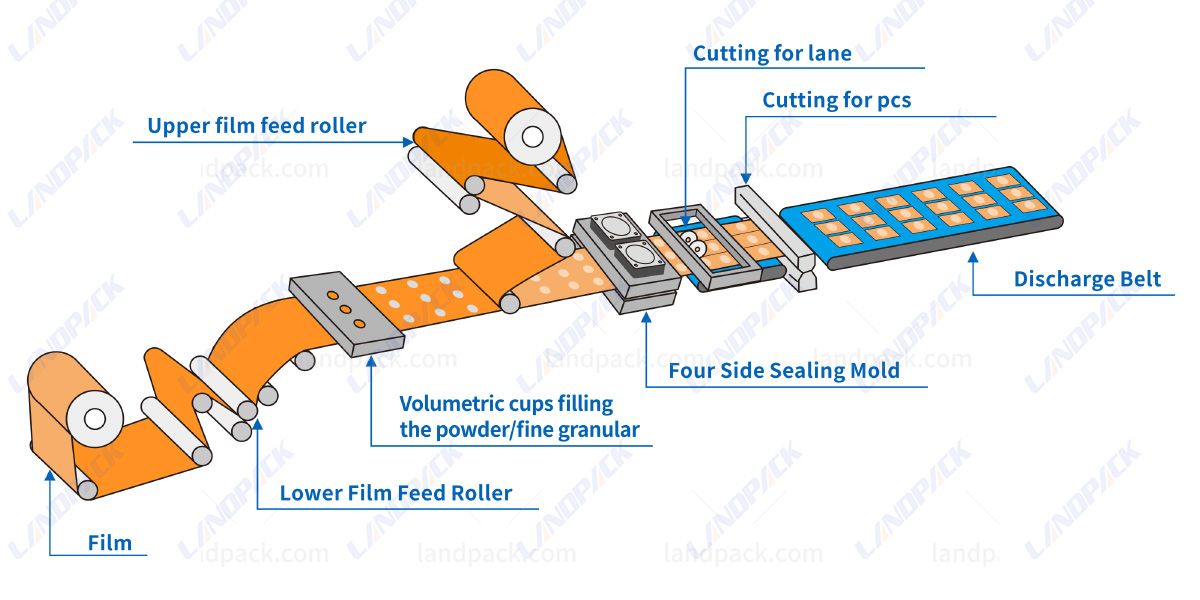

Process Workflow:

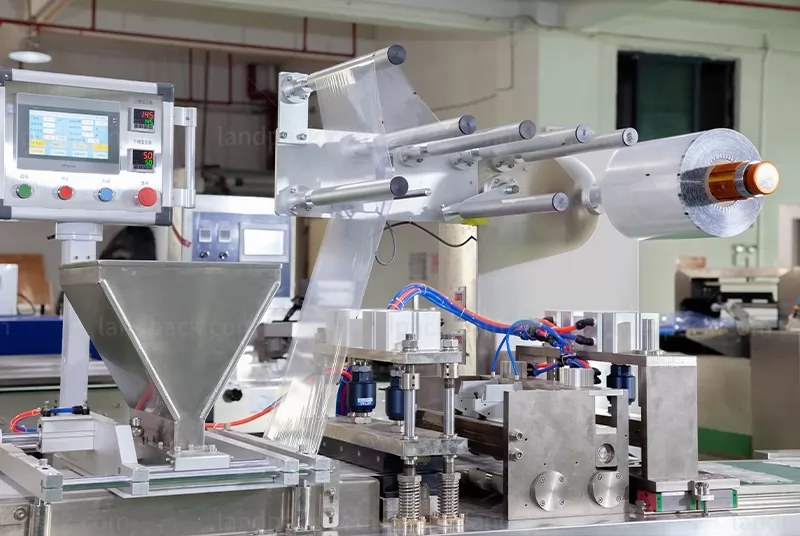

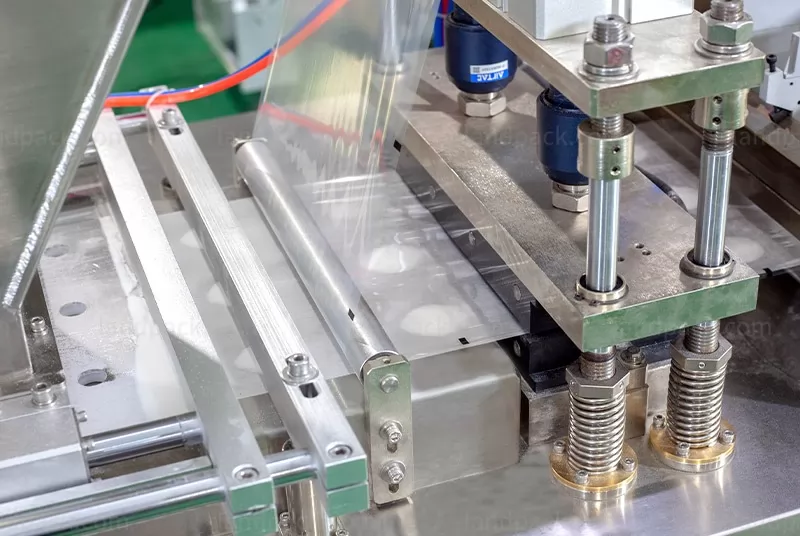

1. Film Unwinding and Material Feed - The film is unwound from the roll and fed through a series of rollers with a dancer-controlled system

2. Pouch Forming - The flat film is shaped into a sachet or 4 side seal bag suitable for the product.

3. Product Filling - The formed pouch is filled with the product

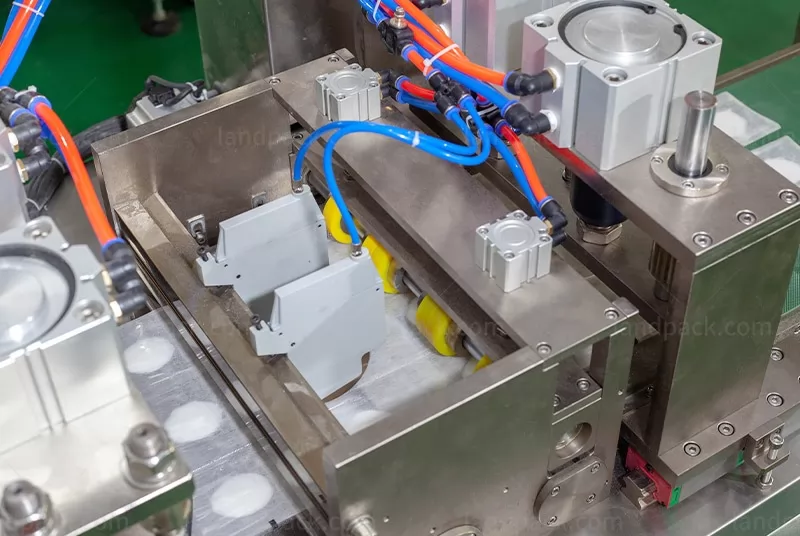

4. Four-Side Sealing - The pouch is sealed on all four sides to create an airtight package

5. Cutting and Discharge - The sealed pouches are cut to the desired size and discharged for further processing or packaging.

6. Control and Monitoring - The entire workflow is managed through an intuitive control interface.