Application:

A 4-sided seal pouch packing machine is used to create pouches by sealing all four sides of a flexible film pouch, protecting its contents from moisture, light, and oxygen - helping keep their freshness longer than otherwise possible.

Suitable Industry:

Below are key applications for this packaging solution:

* Personal Care and Hygiene Products - Facial masks, sanitary napkins, wet wipes, tissues

* Medical and Healthcare Products - Medical masks, ointment patches, medical test strips, single-use medical supplies

* Food and Beverage Products - Dried fruit slices or jerky, single-serve condiments, tea bags or coffee pods

* Stationery and Office Supplies - Cards and stickers, sticky notes or memo pads

* Electronics and Accessories - cables and adapters, screen protectors

Packaging Style:

It can be found widely used for sealing pouches of various sizes with four sides sealing mechanisms - making this device extremely useful in food, daily needs and health products packaging, as well as many other fields. Furthermore, its easy operation provides professional-looking displays.

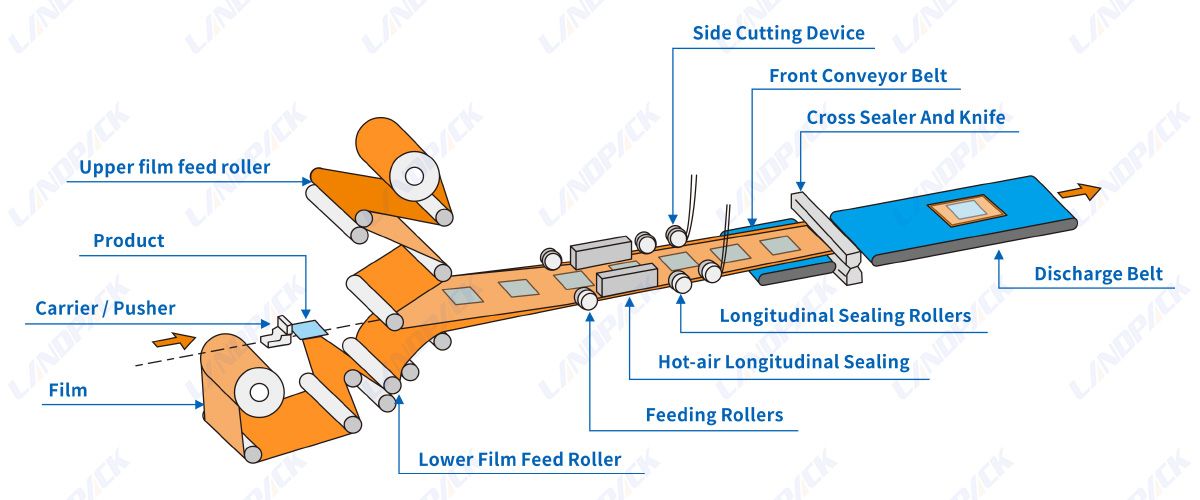

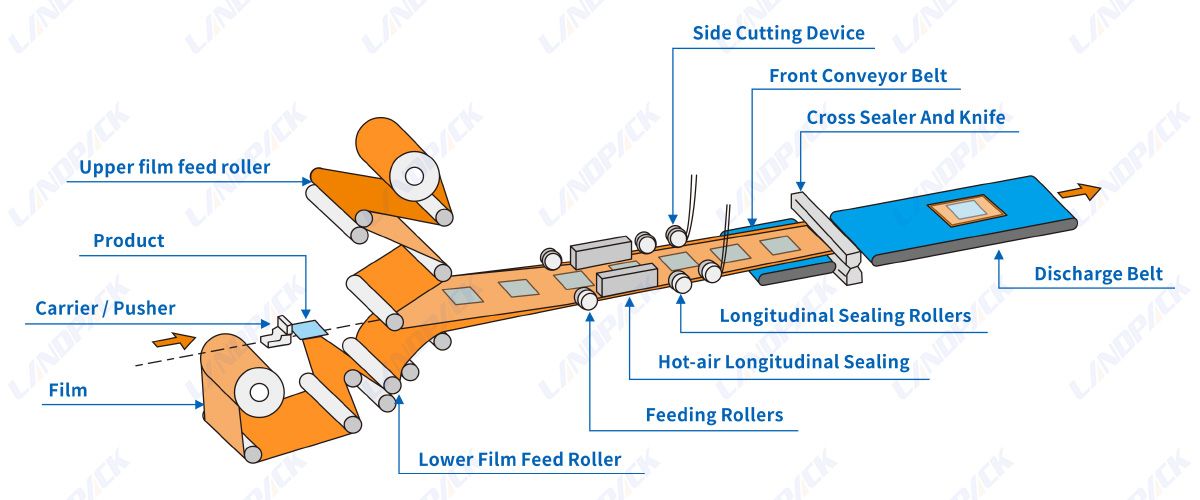

Process Workflow:

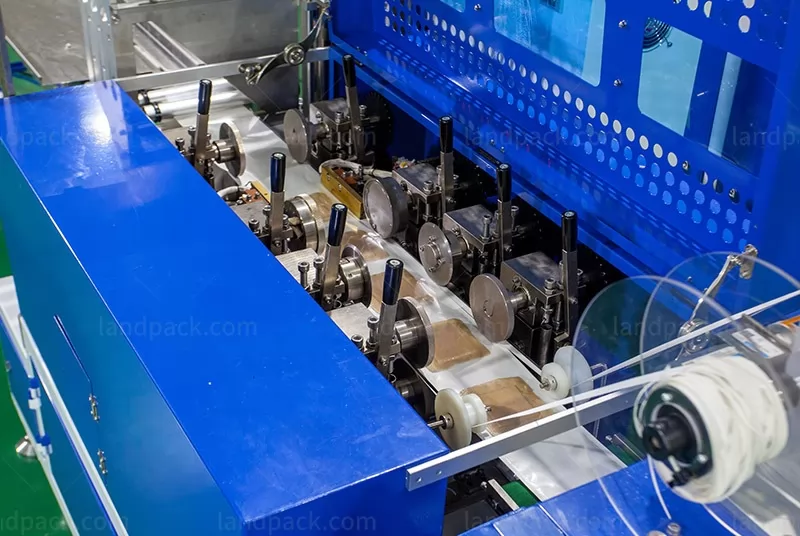

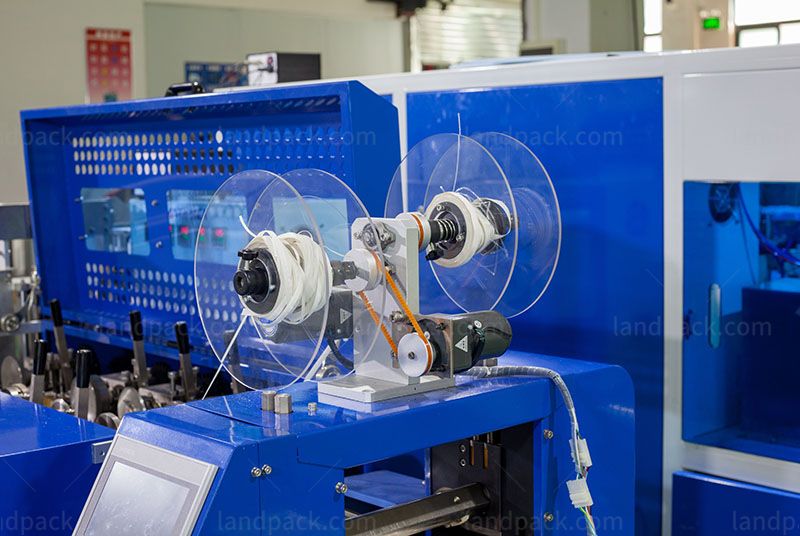

1. Film Unwinding and Material Feed - The film is unwound from the roll and fed through a series of rollers with a dancer-controlled system

2. Pouch Forming - The flat film is shaped into a sachet or 4 side seal bag suitable for the product.

3. Product Filling - The formed pouch is filled with the product

4. Four-Side Sealing - The pouch is sealed on all four sides to create an airtight package

5. Cutting and Discharge - The sealed pouches are cut to the desired size and discharged for further processing or packaging.

6. Control and Monitoring - The entire workflow is managed through an intuitive control interface.