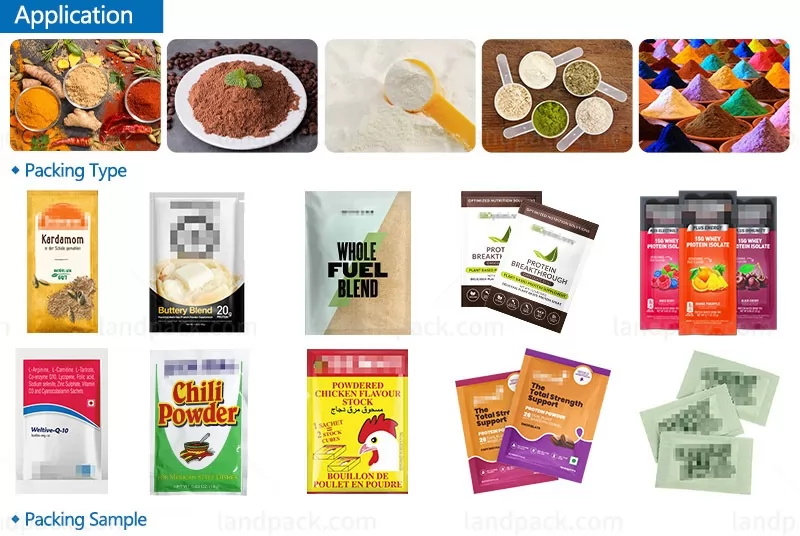

Application:

Powder packaging machines deliver precise metering and attractive four-side-seal packaging, complete with date/batch coding capability and thermal transfer printer for efficient date and batch control. This machine is ideal for packaging a range of powder products, all with an attractive four-side seal finish for professional-looking packaging.

Suitable Industry:

The four-side seal packing machine is an extremely flexible device. Common applications and product types for which it may be utilized:

Food & Beverage Powders - Milk powder, whey protein, coffee powder, flour.

Household / Cleaning / Chemical Powders - Detergent powders, soap powders, silica gel, agricultural additives.

Nutraceutical, Pharma, Cosmetic / Personal Care Powders - Turmeric, body powder, dry pharmaceutical powders, vitamin C powder.

Packaging Style:

It can be found widely used for sealing pouches of various sizes with four sides sealing mechanisms. Furthermore, its easy operation provides professional-looking displays.

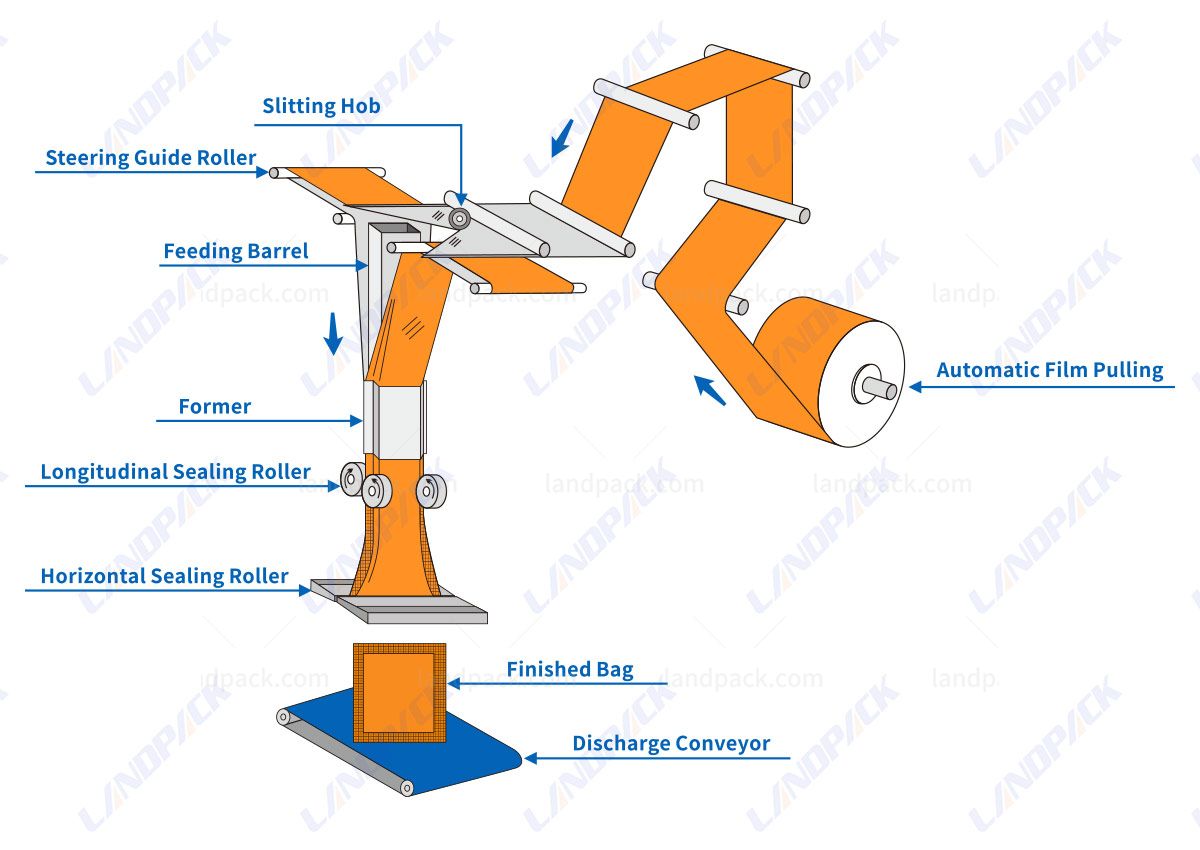

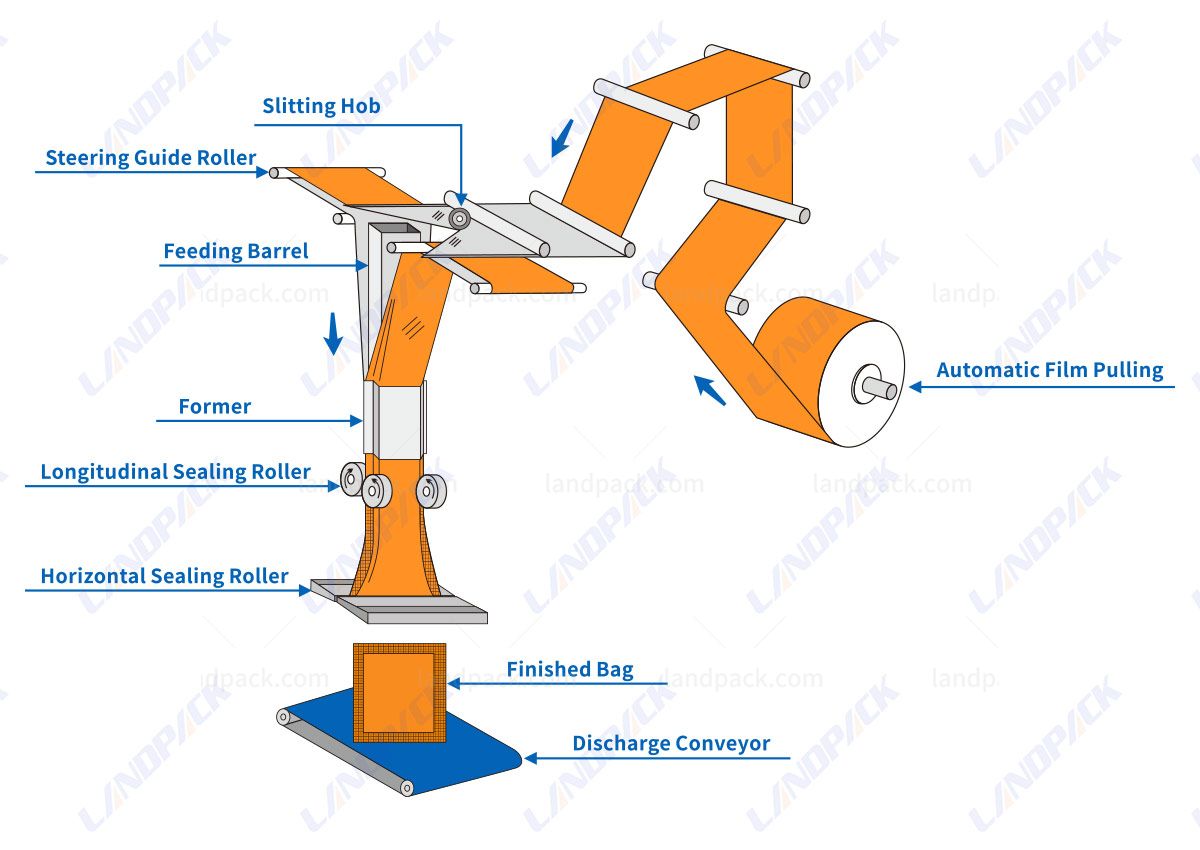

Process Workflow:

1. Film Unwinding & Feeding - A roll of flexible film or laminated composite material is mounted onto an unwind station.

2. Film Steering & Guiding - The film passes through the steering guide rollers to correct any misalignment, ensuring that it is accurately positioned before entering the forming section.

3. Film Slitting & Forming - The slitting hob precisely cuts and splits the film if needed.

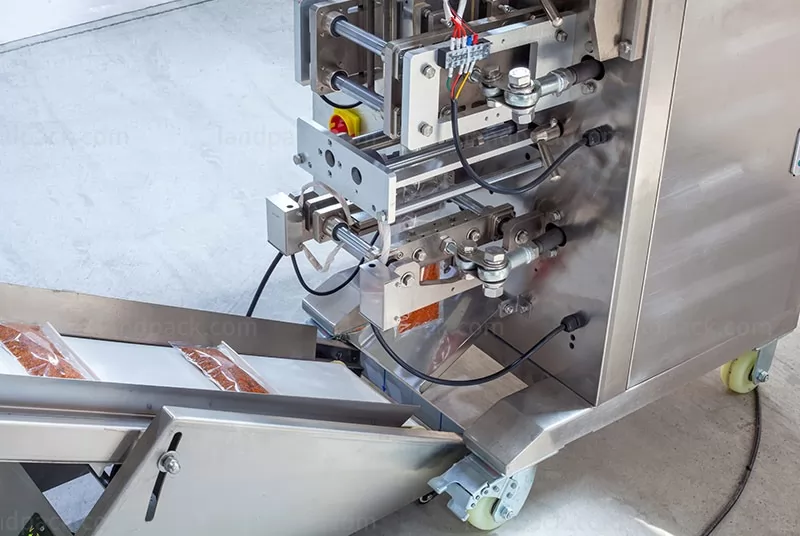

4. Longitudinal Sealing - Heated longitudinal sealing rollers create the vertical seals on both sides of the film, forming the pouch’s four-side seal structure.

5. Product Filling & Horizontal Sealing -Measured quantities of product are dispensated into pouches by means of the filling barrel and sealed by horizontal sealing rollers that create top and bottom seals to fully enclose them.

6. Cutting & Discharge - The machine cuts the sealed pouches into individual bags, which are then discharged onto the conveyor for collection or downstream packaging.