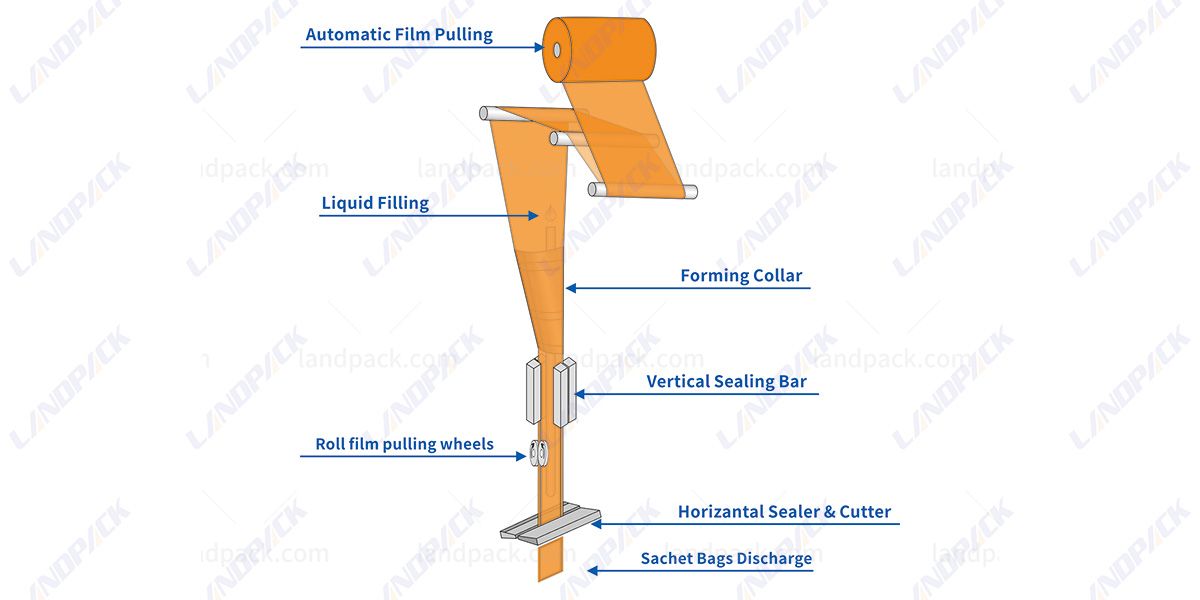

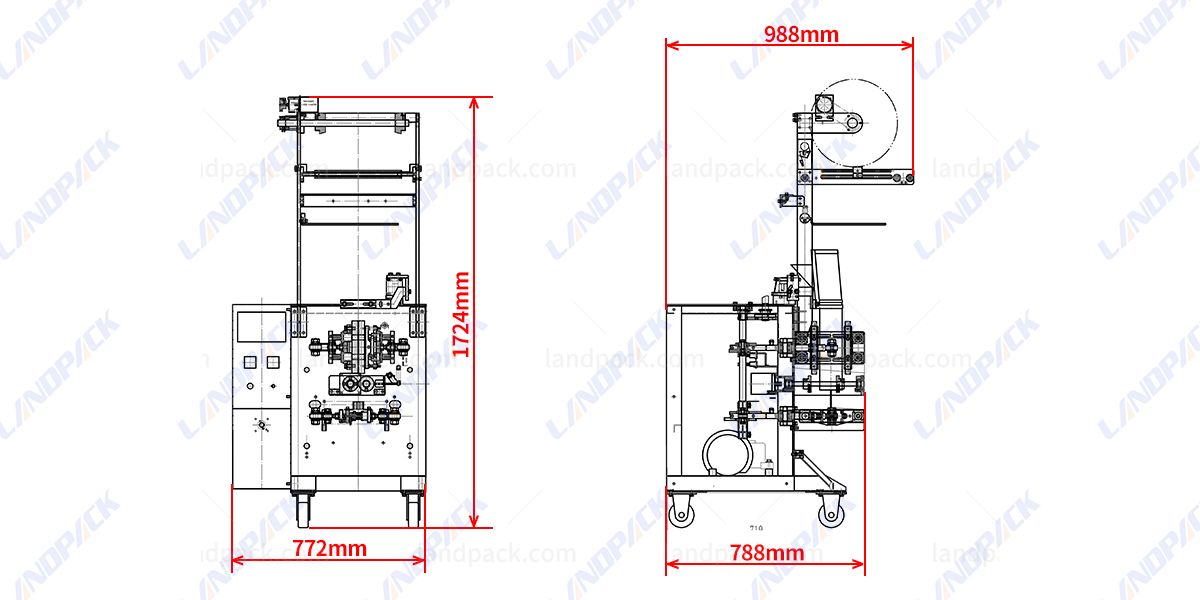

Machine Structure Description:

Feature:

PLC & Servo Intelligent Control System

The machine adopts PLC, full servo drive, pneumatic system, and HMI touch screen as the core control, supporting automatic bag forming, date printing, dosing, filling, sealing, counting, and finished sachet conveying.

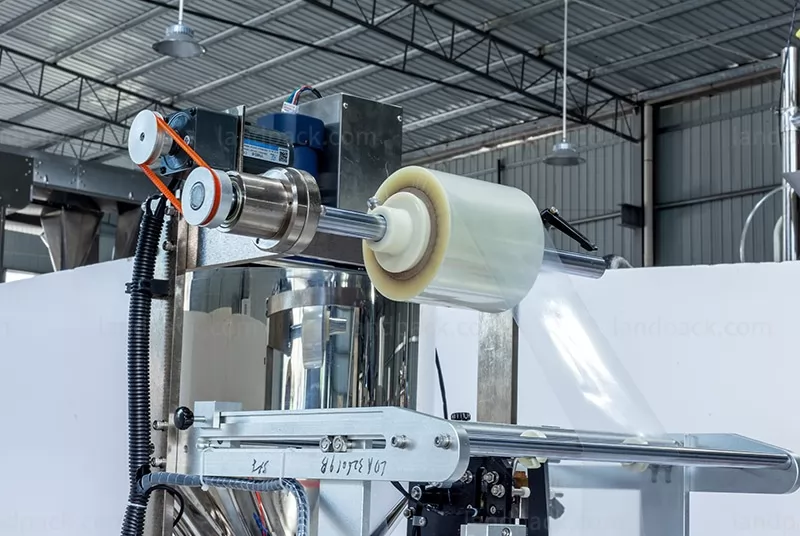

High-Precision Film Pulling & Bag Length Control

Servo-controlled film pulling ensures bag length andsealing quality, fully compatible with different packaging materials and film thicknesses used for ketchup, peanut butter, and other viscous products.

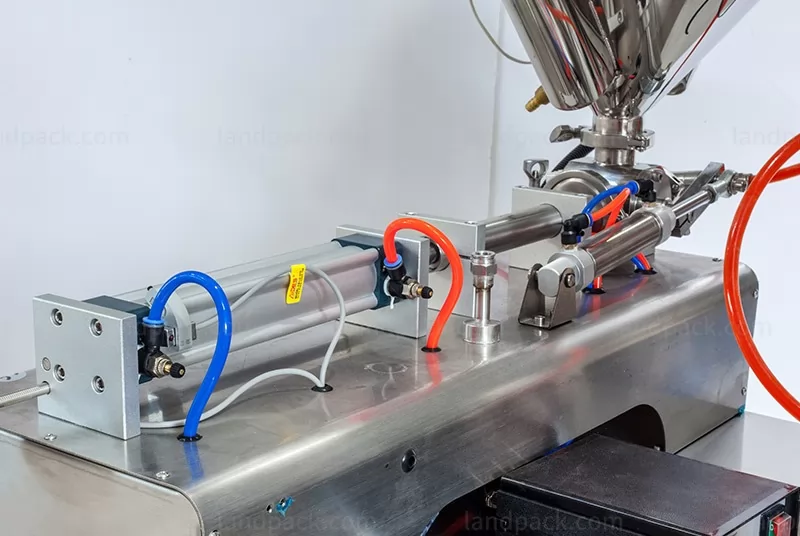

Flexible & Accurate Filling Compatibility

Can be integrated with screw dosing systems, electronic scales, measuring cup systems, or multi-head combination weighers, achieving filling accuracy up to ±1% for paste, liquid, or semi-viscous materials.

Stable Four-Side Sealing Performance

Independent temperature-controlled sealing units deliver strong four-side seals.

Easy Conversion for Different Bag Styles

By replacing the cutting blade, the machine can switch between flat cut and serrated cut sachets; changing the forming mold allows fast adjustment to different sachet sizes and specifications.

High Efficiency & Food-Grade Design

Production speed reaches 30–60 sachets per minute, depending on product and bag size. All product-contact parts are made of SUS304 stainless steel, meeting food hygiene standards and enabling easy cleaning and maintenance.