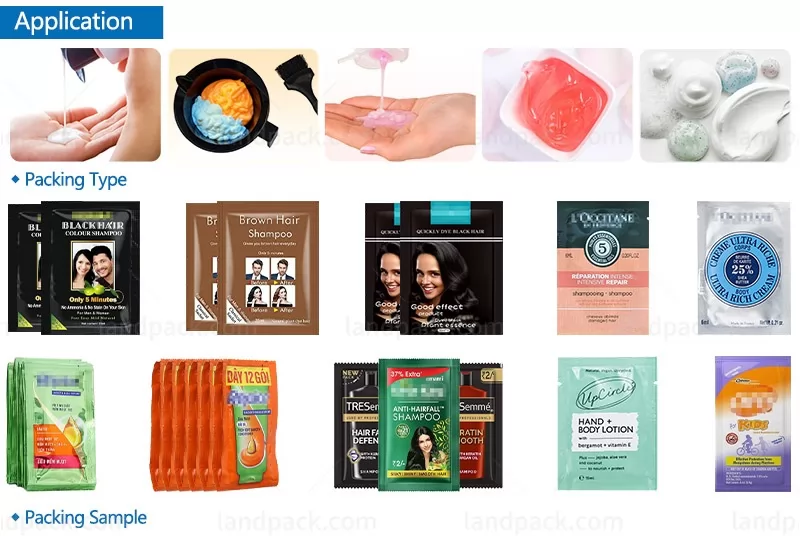

Application:

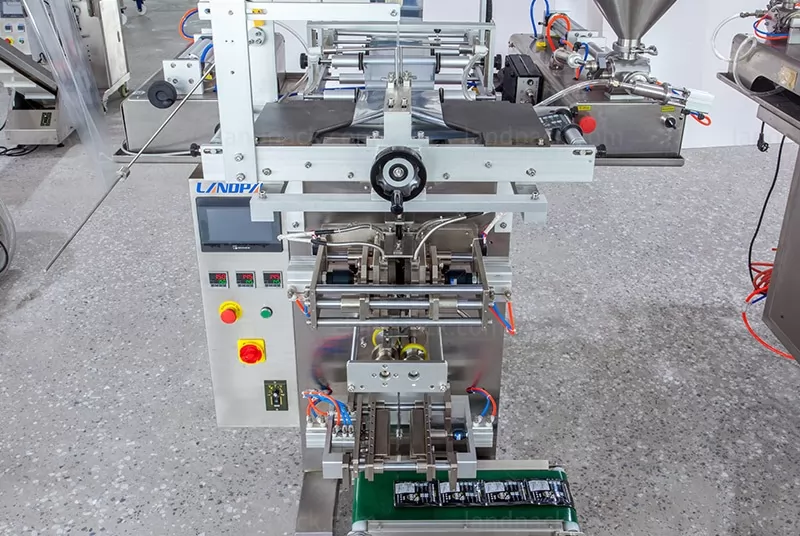

This vertical four-side-seal pouch machine features dual piston-pump filling for precise, hygienic dosing of liquids, pastes, and viscous products. Ideal for sauces, oils, shampoos, and detergents — it delivers leak-proof, retail-ready packages with stable speed and minimal waste.

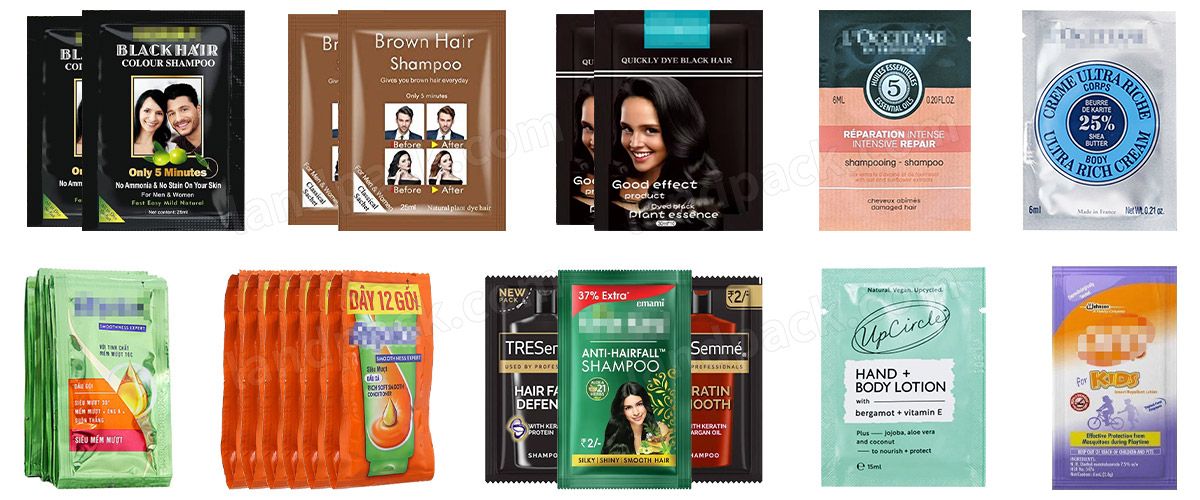

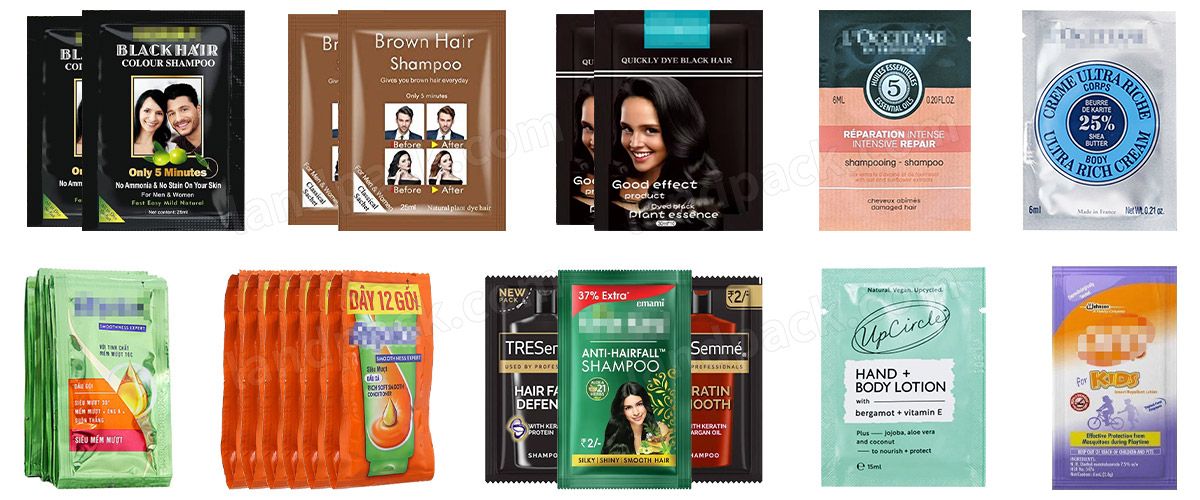

Package Type:

It supports small single-serve pouch formats commonly used for sauces, personal care liquids, cosmetic samples, lubricants, and daily-use household liquids.

Suitable Products:

Equipped with dual piston pumps, this machine is built for consistent dosing of liquids and viscous products used across food, cosmetic, and household industries.

- Sauces & Condiments: Chili sauce, ketchup, soy sauce, salad dressings, flavored oils, liquid seasonings, and cooking pastes.

- Personal Care & Cosmetic Liquids: Shampoo, conditioner, shower gel, lotions, essence liquids, beauty serums, and sample-size skincare products.

- Household & Daily-Use Liquids: Detergents, cleaners, disinfectant liquids, fabric softeners, lubricants, and other fluid household products.

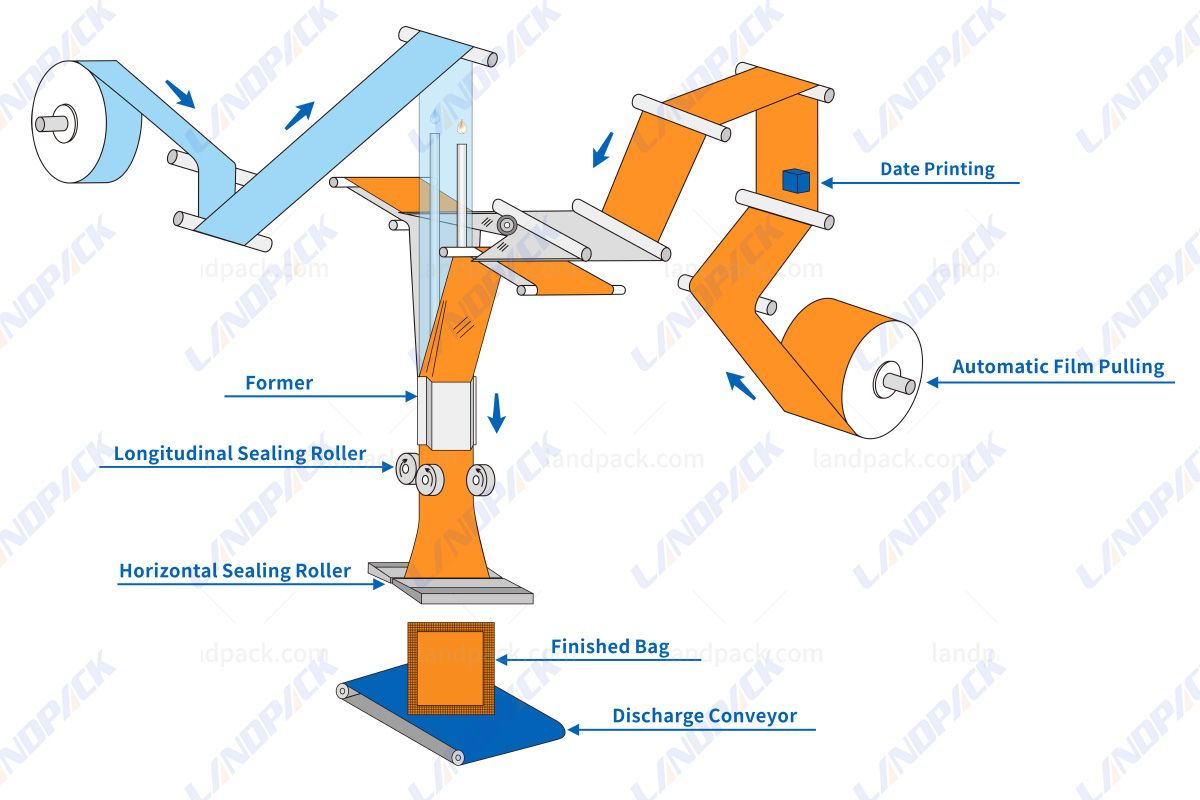

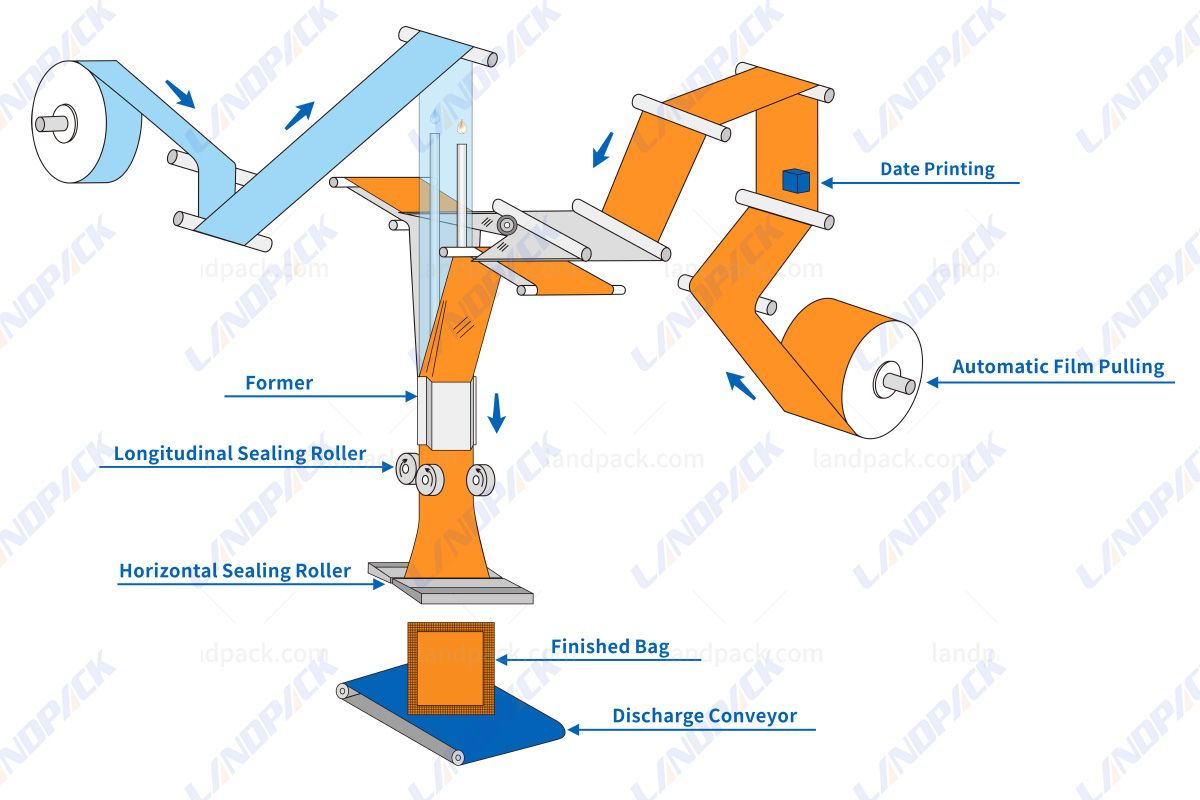

Workflow:

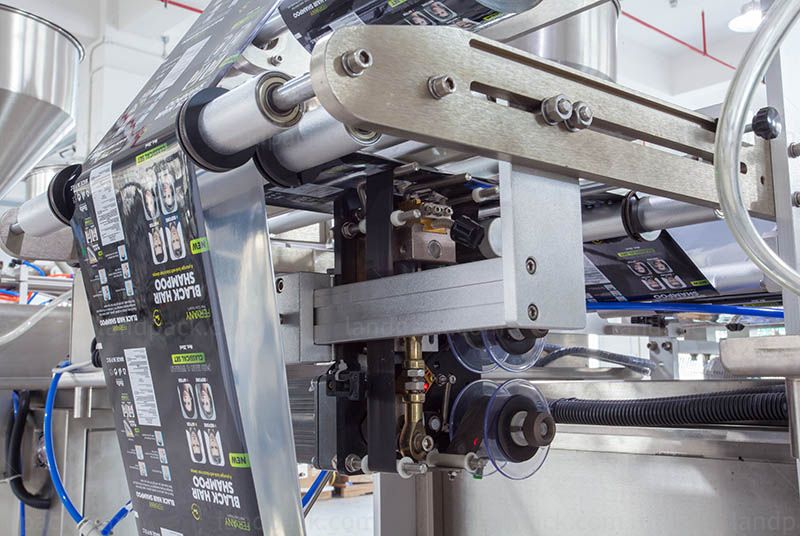

1. Roll Film Feeding - The film roll is automatically unwound and guided into the machine with stable tension control, ensuring smooth forming of 4-side seal sachets.

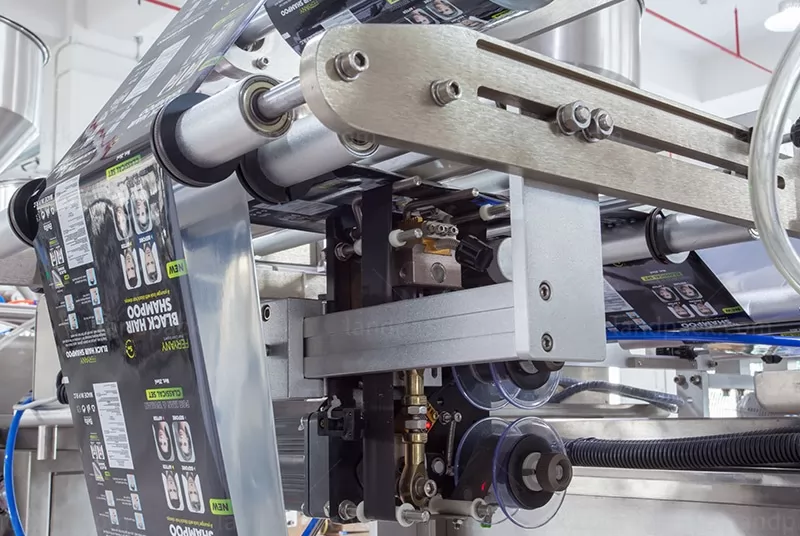

2. Ribbon Date Printing - A ribbon date printer marks each film section with batch codes or production dates before the pouch is formed.

3. Piston Pump Liquid Filling System - Dual piston pumps measure and inject liquid or viscous products with steady, repeatable accuracy, suitable for sauces, gels, and daily-use liquids.

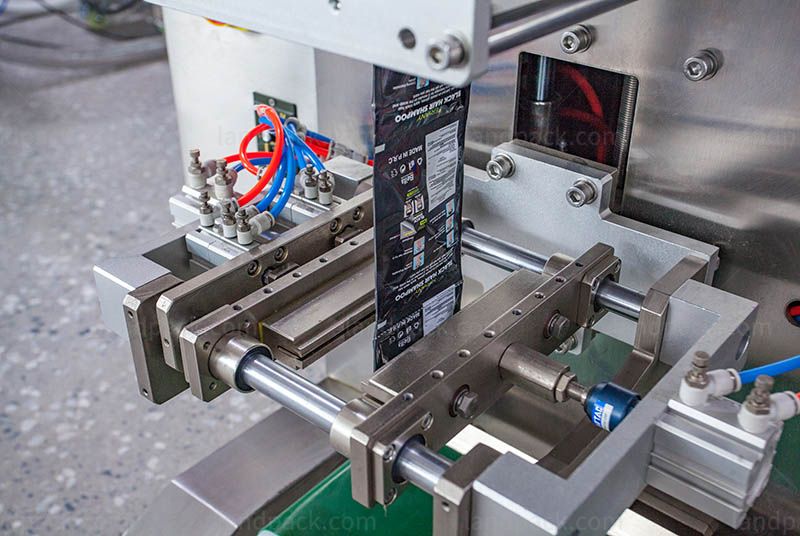

4. 4 Sides Vertical Sealing Bar - The film is sealed along all four edges to create flat sachets with uniform, high-strength seams that prevent leakage.

5. Horizontal Sealing and Cutting - Horizontal jaws complete the top seal and cut individual sachets in one cycle, maintaining pouch consistency at high speed.

6. Liquid Nozzle Drip Tray (Optional) - An optional drip tray collects any residual drops during filling, keeping the workspace clean and improving pouch appearance.

7. Finished Pouch Discharge - Completed 4-side seal sachets are conveyed out for inspection, boxing, or secondary packing.