Application:

The Automatic Shampoo Hair Oil Filling Line is designed for high-efficiency liquid packaging in the personal care and cosmetic industries. This fully automatic bottle filling machine integrates bottle feeding, filling, capping, labeling, and shrinking into one complete filling production line, ensuring accurate dosing, no leakage, and consistent product presentation at a speed of 2500 bottles/hour.

Package Type:

The Automatic Hair Oil Filling Machine With Capping Labeling System can be used for various containers including glass and plastic bottles of different shapes, such as oval, round, flat and square bottles. The packaging of products such as shampoo, body lotions, hair oils, detergents, and disinfectants is handled perfectly by this machine. The line is compatible with different cap types, such as screw caps, flip caps and pump caps. It can handle a variety of liquid products, including shampoo, body lotion, hair oil, detergent, and disinfectant.

Suitable Products:

This automatic shampoo and hair oil filling line is ideal for a wide range of liquid and viscous products across multiple industries:

1. Hair & Personal Care Products: Shampoo, conditioner, body lotion, makeup remover, massage oil.

2. Household & Daily Chemical Products: Laundry detergent, hand soap, mouthwash, disinfectant.

3. Food & Beverage Products: Soy sauce, honey, vinegar, drinks, and other edible liquids.

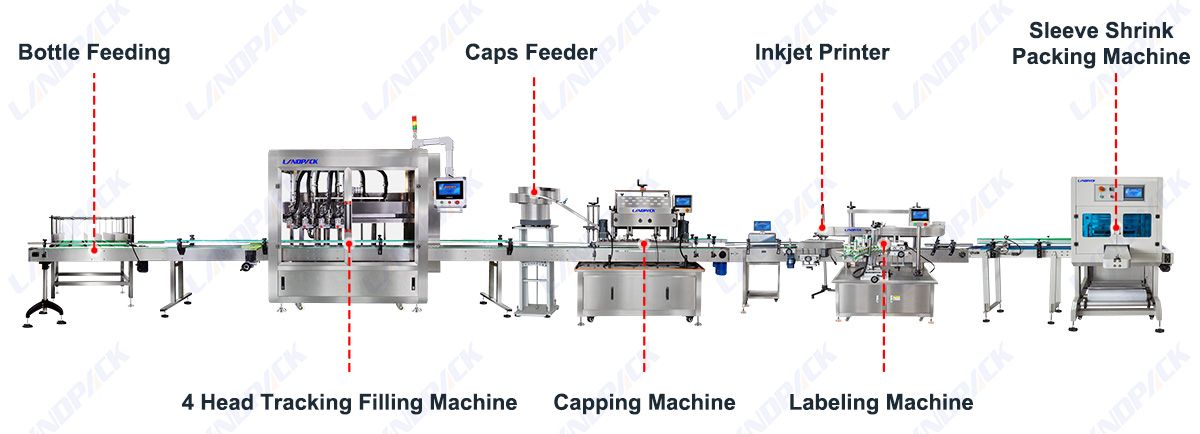

Workflow:

1. Bottle Unscrambler - Arranges and feeds bottles onto the line automatically.

2. Filling Machine - 4 Head Tracking Filler accurately fills hair oil or shampoo.

3. Caps feeder - Sorts and supplies caps automatically.

4. Capping machine - Tightens caps tightly to prevent leakage.

5. Inkjet printer - Prints batch codes and expiration dates.

6. Labeling machine - Applies labels neatly, precisely and accurately.

7. Shrink-Sleeve Machine - Shrinks sleeves to give a finished, clean look.