The process of packing gummy candy might appear simple, but if operating a candy company you'll realize it's not. From counting gummies all the way to sealing bags with precision manual packing is slow, prone to error, and exhausting. This is where a gummy packaging machine can help. It doesn't matter if you need an automated packager for Gummy Bears, or a gummy counting machine, these devices can help you save time, increase accuracy and help your products appear professional. In this article, we'll guide you through the essential information you should be aware of, step-by-step.

Even if you're a small startup, these machines can make your production faster and more consistent.

| Advantage | Why It Matters |

| Faster Production | Pack hundreds or thousands of gummies in less time |

| Accuracy | Counting machines ensure every pack has the exact amount |

| Professional Packaging | Neat, uniform bags or containers look more appealing |

| Labor Savings | Reduce manual labor and errors |

| Flexible Packaging | Works with bags, bottles, cans, and different sizes |

3. Types of Gummy Packaging Machines

Depending on your production needs, there are different types of machines:

1. Vertical Packing Machines

Vertical Packing Machine: Form fill seals automatically. Suitable for start up business.

Vertical Packing Machine with Vibrating Plate: Helps counting and feeding gummies smoothly, especially small or sticky ones, improving counting and preventing jams.

2. Doypack Machines

Mini Doypack Machine: Compact, low cost, easy to operate for startups.

Horizontal pouch packing machine: It can feed single bag or double bags at the same time, which improves speed and efficiency compared with Mini Doypack Machine.

Rotary Packing Machine: High-speed option with multiple stations filling and sealing several bags simultaneously.

3. Filling Machines / Filling Lines

Bottles/Cans Filling Machine: Weighs and fills gummies into bottles or cans.

Bottles Filling Capping Labeling Line: Automates weighing, filling, capping, and labeling.

Cans Filling Seaming Labeling Line: Perfect for canned gummies.

Bottles/Cans Counting Filling Machine: Counts and fills exact gummies into bottles/cans.

Bottles/Cans Counting Filling Line: Combines counting, filling, capping/seaming, and labeling in a fully automated line.

4. How Does a Gummy Packaging Machine Work?

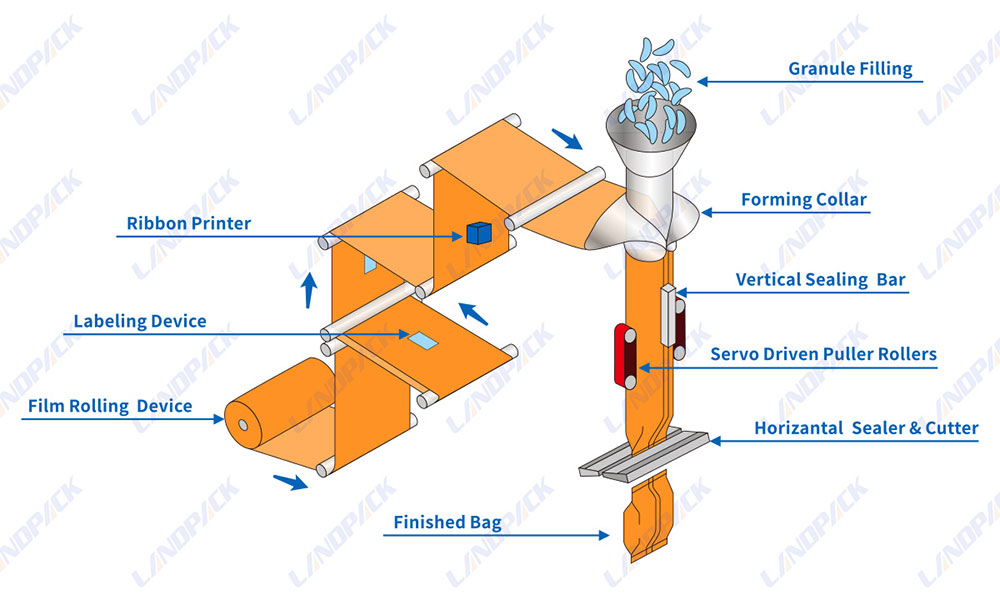

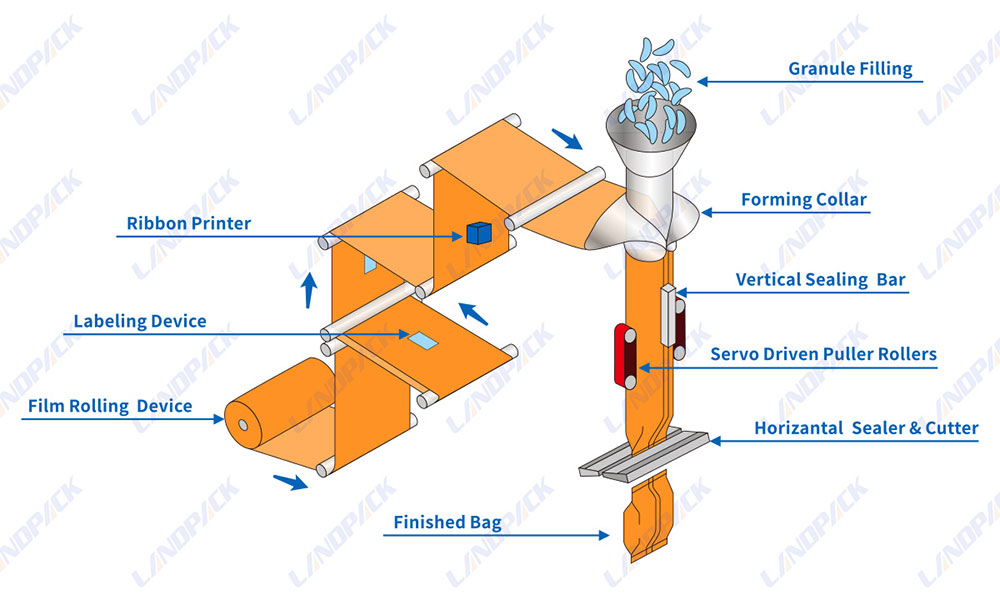

Vertical Packing Machines

1. Feed gummies into the hopper.

2. Bags forming automatically.

3. Gummies are filled, with vibrating plates helping small pieces.

4. Bags are sealed and cut.

5. Finished bags are collected.

Doypack Machines

1. Pouches are picked up and opened.

2. Gummies are deposited using cups, weigher, or gravity.

3. Sealed at the top.

4. Finished pouches output conveyor.

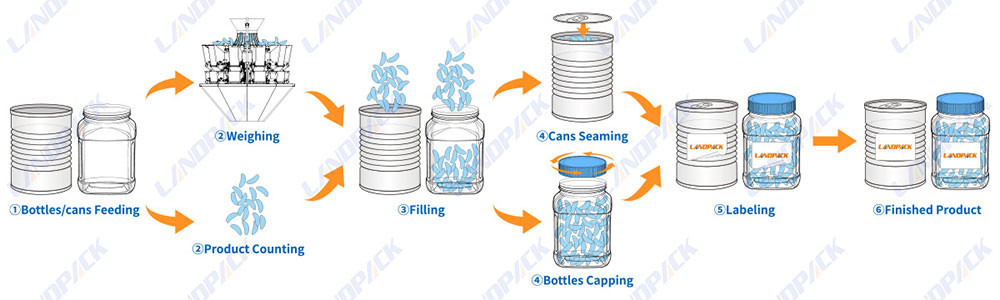

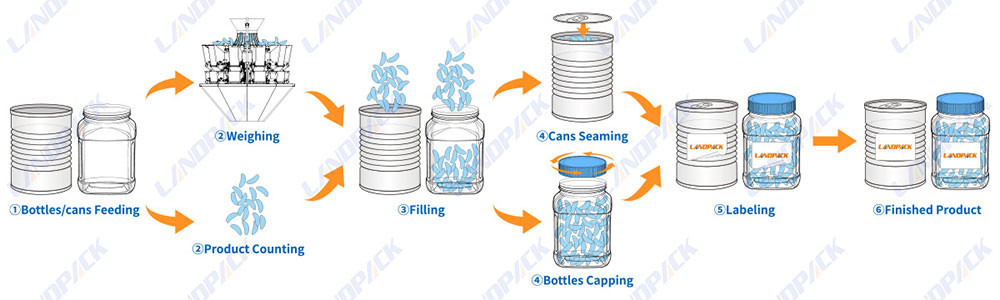

Filling Machines / Filling Lines

1. Bottles/cans are fed onto conveyors.

2. Weighing and feeding into hopper.

3. Gummies are dispensed into bottles/cans.

4. Capping/seaming.

5. Labeling.

6. Finished products outputted.

Counting Filling Machines / Counting Filling Lines

1. Count gummies individually via sensors or vibrating plates

2. Batch filling into bags, bottles, or cans

3. Sealing/Capping/Seaming and labeling automatically

5. How to Choose the Right Gummy Packaging Machine

Choosing the best machine for packaging is an important choice that will affect your production's effectiveness as well as the presentation of your product and the bottom line. With a myriad of options the most appropriate choice is a matter of assessing your requirements across five main areas.

1. Assess Your Production Volume

The output requirements of your business will be the most important factor determining what kind of machine you will require. The equipment you choose to match your needs will ensure the most cost-effectiveness.

Small Batches / Low Volume ideal for small-scale businesses or products that are niche. Small Doypack units or vertical single-station form-fill seal machines provide flexibility, simple switching, a compact footprint and low cost.

Medium Volume / Stable Output: For businesses that are growing. Horizontal doypack machines or vertical counting packing machines can provide faster speeds and automated handling of products to ensure steady, efficient production.

High Volume/Mass Production for large producers. Rotary machines filled with automated lines and counting lines for filling provide maximum speed and constant operation, drastically cutting cost of labor.

2. Define Your Packaging Type

The design the final item determines the kind of machine you choose. Be sure that your packaging vision is aligned with the current technology.

Bags (Pouches) are the most popular type of bag. The range of bags is vast, including bags, premade pouches, M shape pouches, shaped pouches, etc. There's a packing solution for every bag type and production speed, like vertical packing machine, doypack machine.

Bottles & Jars: For rigid containers, you will need automatic filling machines or precision counting filling lines that accurately dispense the required amount of gummies into each bottle or can.

3. Determine the Automation Level & Ease of Use

The level of automation balances your labor costs with your operational complexity and upfront investment.

Semi-Automatic: These machines require some manual feeding. They represent a lower initial investment and are suitable for operations where labor cost savings are not the immediate priority.

Fully Automatic: The complete solution. These systems automatically pick, fill, seal, and label, outputting finished packages with minimal human intervention. They offer the highest long-term labor savings and consistency.

User-Friendly Operation: Modern high-quality machines feature intuitive touchscreen controls and quick-change parts, which simplify setup, operation, and cleaning, reducing downtime and training time.

4. Balance Your Budget & Factory Space

The ideal machine is able to find the ideal balance between cost, performance, and your factory limitations.

Budget Considerations: A higher level of automation usually means a greater upfront expense, but also more long-term savings in labor. Compare your initial investment to your goals for reducing operational costs.

Space Plan: Always confirm the footprint of the machine to ensure that it is a good fit within the factory layout permitting safety in operation, maintenance and the possibility of future expansion.

5. Make a partnership with a Trusted Manufacturer

This is the most important choice. An excellent machine is backed by a top manufacturer.

It is important to partner with a reliable partner such as Landpack Packaging Machinery Co., Ltd. Established manufacturers offer safe, certified equipment. We have a range of custom solutions to meet your needs. We also offer comprehensive after-sales assistance and support to ensure that your line of production will run smoothly for the decades to come.

6. Top Features to Look for in Gummy Packaging Machines

Accuracy: Especially for counting machines and multi head weighers

Speed: We always have the right solution for you, depending on your production volume and speed.

Flexibility & Customization: Bag sizes, pouch types, bottles, cans, even cartoning and palletizing.

Ease of Operation: Touchscreens, simple panels, quick-change parts

Safety & Certifications: CE, ISO, sensor protection, emergency stops and cover.

Durability & Maintenance: Stainless steel, easy cleaning, spare parts availability, and best after sales service.

7. Why Choose Landpack Packaging Machinery Co., Ltd.

Landpack is a leading name among gummy packaging machine manufacturers, offering:

- Experienced Factory: Years of producing packaging machines for candies and snacks

- Customizable Solutions: Tailored machines for any gummy type, bag, bottle, or can

- Certified Quality: CE, ISO, and other safety certifications

- Customer Support: Installation, training, and maintenance guidance

- Global Reach: Exported to 100+ Countries and Trusted by 5,000+ Enterprises

8. Tips for Maintaining Your Gummy Packaging Machine

- Daily Inspections: Belts, sensors and the hoppers

- Cleaning and Lubrication: Maintains the smoothness of the parts and helps avoid jams

- Check for wear and replace components in accordance with the time

- Secure storage: Keep belts and sensors while not when not in use

9. How to Solve Common Problems of a Gummy Packaging Machine

| Problem | Solution |

| Bag not sealing | Check temperature & bag material |

| Counting errors | Clean sensors & ensure proper feeding |

| Jamming | Check gummy size, moisture, feeding flow |

| Machine stops suddenly | Inspect emergency stop buttons & electrical components |

10. Conclusion

A gummy packaging machine is a game-changer for candy businesses. Whether it's an automatic packaging machine for gummy bears or a gummy counting packaging machine, choosing the right machine improves speed, accuracy, and product appearance. Landpack Packaging Machinery Co., Ltd. offers customizable, certified, and reliable solutions to meet your gummy packaging needs - no matter your production scale.

11. FAQs

Q1: Can one machine handle different gummy sizes?

A: Yes, many machines are adjustable for various shapes and sizes.

Q2: What is the typical production capacity?

A: From a few hundred to thousands of bags/bottles per hour, depending on machine type.

Q3: Do small batches need a counting machine?

A: Not always. Mini doypack or single-station machines are sufficient for small-scale production.

Q4: Can Landpack customize machines for my brand?

A: Absolutely! Landpack specializes in fully tailored solutions.